Summary

The use of thermal insulation is a primary approach for reducing heating and cooling loads in buildings, which account for 42 %[1] and 24 % of energy consumption in residential and commercial buildings, respectively. Insulation is added to reduce heat flow in the building envelope, as well as in furnaces and other high temperature equipment installed in buildings. Phase Change Materials (PCMs) integrated into the building envelope can also enhance energy efficiency of buildings as a thermal storage source. This project will develop the measurement science needed to accurately determine the thermal properties of insulation materials, and disseminate the measured data to stakeholders by providing thermal insulation SRMs and calibration services. Furthermore, use of PCMs as a component of the building envelope will be investigated with regard to the need for improved measurements and standards. The primary focus for FY25 is upgrading the data acquisition and control systems of the NIST 1016 mm Guarded Hot Plate (GHP) apparatus and measurements of thermal conductivities and specific heat capacities of thermal insulations and PCMs. Outcomes of these tasks are essential tools for calibrating commercial insulation test instruments and demonstrating the thermal management of PCMs as an envelope component in cooling and heating seasons.

Description

Objective

To improve residential and industrial building energy efficiency by decreasing measurement uncertainties of the thermal resistance of insulating materials and develop measurement techniques for innovative insulation materials and systems using PCMs.

Technical Idea

One of the most cost-effective ways of reducing building energy consumption and associated greenhouse gas emissions is through thermal insulation. Insulation in the building envelope, thermal appliances, and process industries greatly reduces the demand for space conditioning, hot water, and other thermally active processes. Accurate determination of the insulating capability of these materials is critical to achieving the expected energy savings and thermal comfort.

NIST will address this goal by 1) developing and maintaining rigorous quality systems for insulation measurement consistent with standard practices; 2) developing data sets that provide accurate thermal transmission values in wider ranges of temperatures and pressures, and 3) investigating new thermal measurement approaches for innovative insulating materials and systems using PCMs. After achieving high confidence in measurements and promulgating test data, NIST will develop measurement services and reference materials for use by industry in calibrating equipment used to determine the thermal performance of insulation.

A new measurement challenge is determining thermal conductivity and specific heat capacity of innovative insulating materials and PCMs. Innovative insulating materials such as vacuum insulation panels and aerogels have been proposed to reduce heating and cooling loads in buildings, but the measurement challenges, including thermal conductivity measurement, have not been fully solved due to the heat flow, their geometry, or other material properties. Promising results related to the dynamic insulation concept with a switching thermal conductivity pattern depending on the surrounding temperature needs to be considered in conjunction with PCMs for future measurement challenges. In FY24, a transient plane source instrument was used to measure thermal conductivity of various EPS boards and PCM composites. The measured thermal conductivity values of EPS samples obtained from the transient method showed reasonable agreements with HFM. In FY25, NIST will continue using transient methods (transient plane source and transient hot wire) to measure these materials in comparisons with HFM under various conditions

Research Plan

The current year's research plan covers three related areas: 1) updates on data acquisition-control system of the 1016 mm GHP; 2) comparisons of the 1016 mm GHP and 500 mm GHP using SRM 1450e; and 3) developing new measurement approaches for insulations and PCMs. Concurrently, NIST staff will continue to participate in ASTM activities to ensure a path to promulgate products of their research.

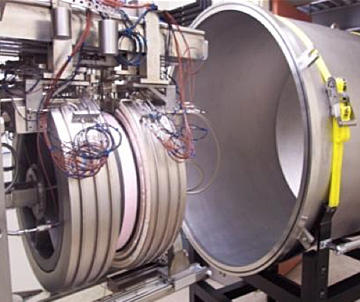

The 1016 mm GHP has been the primary instrument used to provide measurement services for the industry for several decades, but the software and hardware that control its operation are outdated. The fragile system will jeopardize the ability to provide such measurements. Software and hardware that control the 1016 mm GHP will be upgraded, and results will be verified against those previously obtained. This upgrade planned for FY25-26 will allow NIST to continue providing measurement services for the industry as it explores measurement approaches for emerging insulation.

The 500 mm GHP provides a unique measurement capability at NIST to test insulation specimens over wider ranges of temperature and air pressure compared to the 1016 mm GHP. Although measurement principles of the two GHP apparatuses are the same, a different mechanical design to guard the specimens were applied for the 500 mm GHP. In FY25, thermal conductivity data will be obtained from two NIST GHP apparatuses using SRM 1450e at mean specimen temperatures below 60 °C. A level agreement of the measured data will be statistically analyzed. The purpose in doing these tests is to better assess the uncertainty of SRM 1450e by capturing data from two different apparatuses.

The measurement data from the instrument will be prepared for entry into the database after sufficient quality control checks. Furthermore, following successful intercomparisons with the Laboratoire National de Metrologie et d’Essais and the National Physical Laboratory, NIST will prepare data from these intercomparisons and other experiments to populate the datasets intended for release as part of Standard Reference Database 81 (NIST Heat Transmission Properties of Insulating and Building Materials: http://srdata.nist.gov/insulation/). The database provides heat transmission properties – thermal conductivity, resistivity, conductance, and resistance – for building and insulating materials. These data are useful for building designers, material manufacturers, and researchers in the thermal design of building components and equipment.

Innovative insulation materials and PCMs have gained significant research interest to improve building energy efficiency. Several commercial PCM products have been applied in thermal management of various buildings. Depending on encapsulation methods of PCMs, these products form a pouch or grid pattern on a single flexible or rigid board. These non-continuous geometries are difficult to measure using GHP and HFM apparatuses due to inconsistent thermal contact with a hot plate surface. In FY25, NIST will use transient measurement methods to measure thermal properties of raw PCMs and PCM boards and compare the data with a steady-state method (e.g., HFM). Outcomes would result in a draft test method or draft reference material for evaluating these products in future years. Additionally, the performance of these materials is sensitive to installation in wall and roof assemblies. In FY24, NIST began designing a study to evaluate the performance of phase change materials in a small scale model roof. In FY25, that study will continue to help understand how laboratory measurements of phase change materials can be used to assess in-field energy efficiency performance over the course of a year.

REFERENCES:

[1] 2010 Buildings Energy Data Book, Table 2.1.6 and 3.1.5, respectively.

Major Accomplishments

Outcomes:

- Re-issue SRM 1453, Expanded Polystyrene Board, for thermal conductivity by NIST Office of Reference Materials (640).

- Zarr, R. R. and A. L. Pintar, "Standard Reference Materials: SRM 1453, Expanded Polystyrene Board, for Thermal Conductivity from 281 K to 313 K," NIST Special Publication 260-175.

Impact of Standards and Tools:

- NIST-issued Standard Reference Materials for Thermal Insulation mandated by law to be used by insulation industry to meet Federal Trade Commission labeling rules.