Summary

The National Fire Research Laboratory (NFRL) is a facility that enables large scale fire research in the areas including advanced firefighting technologies, engineered fire safety, materials flammability reduction and wildlandurban interface fire. With the completion of a significant facility expansion in 2015, the NFRL is now the premier facility in the world for scientists and engineers to conduct research on the response of realscale structural systems to realistic fire and mechanical loading under controlled laboratory conditions. This project provides support for the basic operations of the NFRL, coordinates research activities, and develops/evaluates metrology to measure structural and fire behavior.

Description

OBJECTIVE:

To develop, improve, and maintain capabilities necessary to safely conduct measurements of large fire behavior and structural-fire response with quantified accuracy.

TECHNICAL IDEA:

The new and unique measurement capabilities of the National Fire Research Laboratory allow scientists and engineers to conduct research on the response of realscale structural systems to realistic fires and mechanical loading ranging in size from small components to large systems (e.g. buildings up to 2 stories in height and 2 bays × 3 bays in plan). Fullydeveloped fires up to 20 MW can be generated using natural gas, liquid hydrocarbons, wood cribs, or actual building contents. Mechanical loading is applied using hydraulic actuators or fixed loads.

The NFRL is used to safely conduct fire and structural fire experiments, enable fire model validation studies, enable advances in codes and standards for structures in fire conditions, and support building and fire safety investigations and post disaster and failure studies. To meet the technical needs of the NFRL customers, new instrumentation and standardized test methods are developed to provide reference data for comparison against numerical predictions at multiple levels: single element scale, sub-assembly scale, and complete structures. Focus is placed on improving the measurement capabilities of the large fire calorimeters and relevant measurements for structure performance, such as strain and displacement. We will use statistical methods for uncertainty analysis and computational fluid dynamics modeling to systematically examine and improve the heat release rate (HRR) measurement system. Using the new NFRL capabilities, NIST will develop experimental data on the performance of largescale structural systems under realistic fire and mechanical loading. We will also develop new data acquisition and control methods, which will improve the measurement and safety systems in the expanded NFRL.

RESEARCH PLAN:

In the spring of 2014, NIST conducted a stakeholder workshop on the current and future direction of structural fire resistance research. The product of the workshop was an International R & D Roadmap for Fire Resistance of Structures. The roadmap emphasizes a multiyear, multiinstitution, largescale experimental program to support performancebased engineering and modeling/simulation. The NFRL research plan, experimental work, and associated model evaluation studies are directly aligned with the recommendations from this workshop and the roadmap.

The successful operation of the NFRL relies on uninterrupted service of several critical infrastructure systems. The operation, maintenance, and repair of these systems, such as the NFRL Emissions Control Systems are managed through this project. New instrumentation, data acquisition systems, and measurement test fixtures are developed and maintained. A new fuel delivery system was installed. Oxygen consumption calorimetry for the new hood and the NFRL Operations and Control Center instrumentation was completed. This allows both calibration of the new 20 MW calorimeter (15 m), as well as improvement of the operating capabilities of the three existing (3 m, 6 m, and 9 m) large calorimeters. The best practices (SOPs) for NFRL laboratory activities are refined, documented and include safety operation requirements.

New measurement capabilities are developed to allow accurate quantification of structural response parameters in a fire environment. Measurements under realistic fire conditions require instrumentation that can both withstand the harsh fire environment and account for thermal effects on measurement quantities. These measurement capabilities don’t exist or haven’t been validated in scenarios with open flames. Reliable and accurate measurement of deformations and strains in structures are essential for experimental control, safety, and the validation of computational models of fire effects. To measure displacement, multiple technologies are being investigated: mechanical (point), laser (point or line) and imaging methods (full-field). To measure strains, the two most promising approaches are based on photogrammetric methods and fiber-optic strain gages.

Electro-mechanical devices that measure displacement, such as string potentiometers, which are relatively inexpensive and widely used for room-temperature measurements, are being augmented to measure in fire environments. We compensate for unwanted thermal expansion of the probe that transfers displacements from the structure to the sensor by either measuring the change of resistance in the transfer wire (which varies with temperature) or by taking two simultaneous measurements using non-metallic fibers that exhibit distinct, nearly-linear displacement response at temperatures exceeding 1200 C.

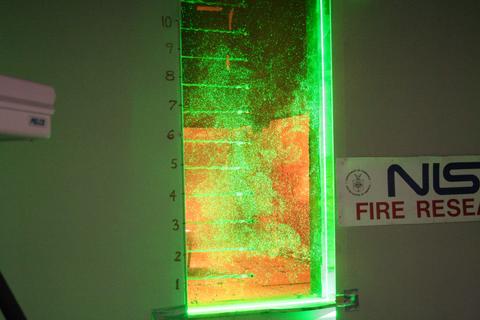

Commercially available laser displacement sensors that use triangulation or time-of-flight principles are being tested for suitability for use in open flames. The application of blue spectrum (405nm) lasers is particularly promising as they are less sensitive to error caused by radiation emitted in the red spectrum than the more commonly used red lasers. Coherent LADAR systems are also being investigated to generate 3D point clouds of object shapes and deformation in fire.

Imaging-based measurement methods such as Digital Image Correlation (DIC) offer the potential to provide full-field strain and displacement measurements over large regions of a specimen Digital Image Correlation photographically monitors the evolution of a random, highcontrast pattern of light and dark regions that define, through their gray level, a region that can be located in each image. Several candidate methods for marking this pattern on structural specimens have been identified, and must be evaluated. Small scale tests will be conducted with strain measurements validated by traditional extensometry methods to assess the accuracy of the DIC methods.

Fiber optic sensors measure strains and temperature at multiple points along the length of the fiber. The optical fiber must be either attached to the surface of a steel component or embedded in a concrete section. Similar to resistive strain gages, attachment methods other than epoxy bonds are required at elevated temperatures. Attachment methods between the fiber optic sensor and/or fiber and the steel or concrete component are not well developed for fire conditions.

Exploratory testing using various methods will be used during the NFRL experiments to assess the accuracy of these methods in measuring displacements and strains in a structurefire test in the NFRL, and to quantify the uncertainties associated with such measurements.

Accurate characterization of the fire environment is necessary to correlate the structural performance measurements to the thermal loading of the structure. This will provide fundamental data that allows performance evaluations and ultimately performance predictions of structural members when exposed to fire. New measurement capabilities will be implemented and developed to generate accurate measurements of the fire environment and therefore provide experimental data to support the development of models for interfacing computation fluid dynamics and structural simulations.

Improvements to the large scale heat release rate measurement, the primary measurement of fire hazard, will be implemented, such as improved calibrations, flow measurements, and overall characterization of the system to make significant reductions in the measurement uncertainty. Deployment strategies for thermocouples and infrared cameras will be implemented to improve surface temperature measurements. New measurement methods to accurately quantify the heat transfer to structural members will also be considered. Strategies to infer parameters, such as fire growth, fire spread and event correlation, from video documentation of the fire will provide supplemental and valuable data.

New instrumentation will be procured and deployed to measure post fire gas species composition and soot particulates. The measurement of soot used light extinction and volatile organic compounds using FTIR technology will help improve the heat release rate accuracy, provide data for model validation and provide data needed to demonstrate compliance with environmental requirements. The FTIR measurement will also be used to quantify acid gases and SF6 tracer gas dilution for volume flow rate verification.