The act of grasping and shaking hands is a defining human ritual, with the grip intimating traits of each person involved. But what about our android counterparts?

What does the grip of a robot's hand say about the machine's capabilities, especially its dexterity—the ability to wield and manipulate different objects under challenging circumstances, such as in manufacturing or assembly operations?

Researchers at the National Institute of Standards and Technology (NIST) are developing tests to take full measure of robotic grasping—specifically, the motion and effort that gripping and manipulating entail. Their immediate goal: To provide useful performance-benchmarking tools to support research and innovation leading to ever-more handy capable robot appendages.

Ultimately, the team aims to create a suite of metrics and tests that manufacturers can use to assess whether a particular robot has the fine-motor skills necessary to perform different types of tasks in a factory.

University and industry robotics experts will get a chance to review the first set of NIST tests during the May 30 Workshop on Robotic Hands, Grasping, and Manipulation in Seattle. Held in conjunction with ICRA 2015, a conference organized by IEEE's Robotics and Automation Society, the workshop will survey the current state of practice and research on robot dexterity.

"Intelligent grasping requires precise control of motions and forces," explains NIST mechanical engineer Joe Falco. "This level of control results from the effective coupling of hardware—robot hands—and software, especially the algorithms that function like a brain. The performance of both parts of this combination needs to be benchmarked."

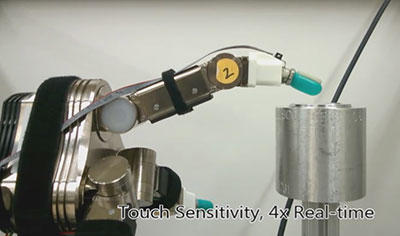

Falco and colleague Karl Van Wyk will demonstrate six tests, developed with an informal working group of collaborators that included start-ups, a U.S. auto manufacturer, and several universities. Designed for easy set-up and to accommodate most budgets, the tests measure touch sensitivity (the force exerted at the point of contact), finger and grasp strength, resistance to slipping, and a finger's ability to maintain contact at the desired level of force.

"We'd like the participants to react to and comment on the metrics and test methods and to propose improvements or additions that can increase the usefulness of these tools," says Elena Messina, who leads NIST's Robotic Systems for Smart Manufacturing Program. "We're offering these tools as a starting point for a community-driven effort to develop and implement standardized performance measures."

Called hands, grippers, manipulators and end effectors, the business ends of robots are now largely single-purpose tools, designed to grasp parts with a specific shape at a defined orientation. However, more capable, multiple-function grippers with hand-like capabilities are edging into the market, opening the way to more flexible manufacturing operations that are geared to small-batch production of multiple products.

On the way toward a universal gripper—the field's holy grail—test methods will help the research community communicate results, compare designs, and identify opportunities for progress.

At the workshop, Van Wyk also will report results of his efforts to develop an automated, force-based control strategy that coordinates "digits" on a multi-fingered robotic hand and enables robust grasping and manipulation of objects.