Summary

Currently there is a significant interest in using additively manufactured parts in high-performance applications. However, due to a lack of publicly available high-fidelity additive manufacturing (AM) material properties data, confidence levels in such parts are low, creating a technical barrier to widespread use of this technology. Solving this problem is not trivial, since the large number of AM machine manufacturers, large number of process variables, evolution of machine control software/hardware versions, and the lack of standard measurement methods and test protocols for AM materials make it difficult and extremely expensive for private industry to develop consensus materials property data that has a good pedigree. Currently, individual companies use home-made methods, or existing material standards that are not AM-specific, nor necessarily AM-appropriate, in a case-by-case manner. Our approach is to develop new characterization methods that expand or replace traditional material characterization methods in order to qualify and quantify the unique attribute of AM materials. NIST will deliver new measurement methods, protocols, exemplar data, and databases to mitigate these issues. This will accelerate proliferation of AM parts in high-performance applications that can benefit from AM’s unique capabilities. This will be of particular benefit to those industries that can take advantage of highly-complex, customized metal parts that can be made via AM, such as the aerospace, bio-medical, and defense industries.

Description

Objective: Deliver new standardized feedstock and AM-built material characterization methods, exemplar data, and databases to accelerate the design and use of additive manufacturing parts in high-performance applications (e.g., critical parts in high-stress applications such as turbine blades or engine components).

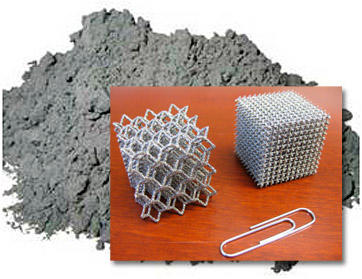

Technical Idea: New measurement methods, protocols, exemplar data, and AM material databases are needed to enable widespread use of AM technology for high-performance applications. Standardized methods for characterizing metal powders (from the powder metallurgy industry) and for characterizing the mechanical properties of metal parts already exist. However, these methods have limited applicability to AM parts and AM powders. These existing methods do provide the foundation for new, AM-specific characterization methods and protocols that will expand or replace these traditional material characterization methods in order to qualify and quantify the unique attributes of AM materials. Publicly accessible exemplar AM materials data will help technology developers and end users to improve their process models and optimize the process parameters leading to elevated confidence in AM processes and resulting materials.

Research Plan: Our approach is to develop new characterization methods that expand or replace traditional feedstock and material characterization methods in order to qualify and quantify the unique attribute of AM materials. Traditional methods will be used first to assess their limitations in AM applications. The new methods will be developed and applied to feedstock used in AM processes and AM-built materials, especially those high-priority materials that are of particular interest to the aerospace industry. The characteristics of feedstock materials (metal powders) will be studied to identify their effects on the mechanical properties of AM-built materials. Similarly, the effects of AM process parameters on the mechanical properties of AM-built materials will be investigated.

Exemplar data will be generated from the above mentioned empirical studies and through well-designed round robin studies with various high-priority materials. This data will be used to further investigate the relationships between process parameters and material performance. The effects of process parameters, machines, and build environments on the variations of resulting material properties will be studied. All traceable measurements of process and resulting parts will be curated with all other relevant information in a high-fidelity AM material property database that is publicly accessible for further analysis and use. The demonstration database will be developed in collaboration with similar efforts by other industrial and academic institutions and will be periodically updated based on the feedback received from the public.