Summary

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Approximately 1,300 machines per year are evaluated for conformance with the ASTM E23 and ISO 148-2 standards for our customers around the world. Machines certified according to ASTM E23 through the NIST system provide results within 5 % or 1.4 J (whichever the largest) of one another, which is the narrowest distribution of impact results in the world.

Description

The Charpy test is a high loading rate test that measures the energy absorbed during fracture, hence providing an indirect measure of impact toughness. For a Charpy machine to maintain an accurate absorbed energy scale, periodic verification with certified specimens is required. To achieve the required accuracy, NIST maintains three reference machines (in accordance with ASTM E23). The average absorbed energy for samples from a given lot tested on these machines is the certified value for the lot.

The program provides a complete certification service. SRMs manufactured to NIST specifications and certified on our reference machines are sold to customers for verifying the performance of their machines. After customers test the SRMs, they return test results and digital pictures of tested specimens to NIST. Based on our evaluations, we will either issue a certificate of compliance (Verification Letter) or provide suggestions for improvement. The verification results are stored in a database, which is valuable for tracking quality of individual machine performance and for trend analysis to evaluate proposed changes to ISO and ASTM standards.

Since 2016, ASTM E23 covers Charpy strikers having an edge radius of 8 mm (as in the past) and 2 mm (previously only covered by ISO 148:2). Since December 2017, NIST offers Charpy verification specimens for both types of strikers (8-mm and 2-mm). The specimens for 2-mm strikers are only available as Self-Verification (SRM 2197 and SRM 2198, information in Table below).

Recent News

Certified low- and high-energy Charpy specimens available for testing at 21 °C (70 °F).

SRMs 2092 and 2096 (low-energy and high-energy, -40 °C) have been discontinued.

The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C. These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:

- Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),

- Low-energy: SRM 2562 (Self-Verification, 21 °C, 8 mm strikers),

- High-energy: SRM 2563 (NIST-Verification, 21 °C, 8 mm strikers),

- High-energy: SRM 2564 (Self-Verification, 21 °C, 8 mm strikers).

The corresponding NIST-verification SRMs for -40 °C testing (SRM 2092 and SRM 2096) have been discontinued, and will not be available anymore. The -40 °C self-verification SRMs (SRM 2093 and SRM 2097) will remain available, however.

The acceptable test temperature range for low-energy specimens (SRM 2561 and SRM 2562) is 21 °C ± 1 °C (70 °F ± 2 °F), while high-energy specimens (SRM 2563 and SRM 2564) must be tested at 21 °C ± 3 °C (70 °F ± 5 °F). The same range (21 °C ± 3 °C) can also be used for super-high energy specimens (SRM 2098 and SRM 2099).

The reason for the narrower test tolerance temperature of low-energy specimens is that these exhibit ductile-to-brittle transitional behavior at 21 °C, while high-energy specimens are fully ductile at this temperature. For more details, visit https://doi.org/10.6028/NIST.IR.8470.

If the ambient temperature of the testing laboratory is outside the acceptable ranges specified above, the same cooling equipment previously used for -40 °C testing should be employed. Alternatively, users can purchase SRM 2093 and SRM 2097 for the indirect verification of their machine at -40 °C.

Electronic Submission of Results for the Indirect Verification of Charpy Machines

For the fastest and most efficient response, we recommend our customers to submit their results electronically, following the instructions for electronic submission of Charpy results. We will provide remote evaluation of your indirect verification results through the verification of your questionnaire and the inspection of your test samples in the form of high-quality digital pictures.

Software for Instrumented Charpy Analysis — NICAS

We have created a software package in LabVIEW that allows analyzing Instrumented Charpy Tests in accordance with ASTM E2298 and/or ISO 14556. The software is available for free download on GitHub, one of the world's leading software development platforms (https://github.com/usnistgov/Charpy).

The software package, called NICAS (NIST Instrumented Charpy Analysis Software), has been developed by Damian Lauria from the Advanced Chemicals and Materials Division of MML, Fatigue and Fracture Group, based on input provided by Enrico Lucon.

The source code was written in LabVIEW 16.0.1 for Windows 7 or later, and should be compatible with all newer versions of LabVIEW. Any executable will require the LabVIEW Run Time Engine (RTE) 16.0.1 or later. The RTE can be downloaded free of charge. Also included are several sample data files and the User's Manual for the software (NIST IR 8302).

If you have questions, comments, or complaints, please contact Enrico Lucon (enrico.lucon [at] nist.gov (enrico[dot]lucon[at]nist[dot]gov)).

Free Macro-Enabled Spreadsheets Available for Obtaining Charpy Transition Curves

The Advanced Chemicals and Materials Division and the Statistical Engineering Division of NIST have developed a software package that allows developing transition curves for Charpy or toughness data as a function of temperature. Five different fitting models are considered (hyperbolic tangent, asymmetric hyperbolic tangent, Burr model, arctangent, and asymmetric Kohout model). The software package is made available free of charge to the public, and consists of the following items:

- Microsoft Excel macro-enabled spreadsheet for establishing initial values of model parameters.

- Microsoft Excel macro-enabled spreadsheet for a basic-level analysis (fitting parameters, characteristic temperatures, model selection statistics).

- Shiny App (web-based interface for R code) for an advanced-level analysis (fitting parameters, characteristic temperatures, model selection statistics, confidence intervals, and uncertainties for the estimated parameters).

Detailed instructions for using the software package are provided in NIST Technical Note 2158, published in May 2021. Please send comments and suggestions to Enrico Lucon (enrico.lucon [at] nist.gov (enrico[dot]lucon[at]nist[dot]gov)).

Additional NIST Charpy Services

The NIST Charpy Verification Programs offers the following additional services:

- Certified reference specimens for the indirect verification of Charpy machines equipped with a 2-mm striker (only in the form of Self-Verification specimens, see SRM 2197, SRM 2198, and SRM 2199 below).

- Upon request, NIST official letters covering the indirect verification of a Charpy machine in accordance with ISO 148-2 (as well as ASTM E23 verification letters).

NIST Charpy Instructional Videos

A specific web page is available, NIST Charpy Verification Program - Helpful Videos, with videos designed to instruct or inform customers on specific Charpy-related activities. Please contact enrico.lucon [at] nist.gov (enrico[dot]lucon[at]nist[dot]gov) with comments.

NIST SRMs for Indirect Verification of Charpy Impact Machines:

(Links to purchase each SRM are available at: https://shop.nist.gov/)

| Absorbed energy (machines with 8-mm strikers) | SRMs 2561, 2563, and 2098* | NIST verification (8-mm strikers, 21 °C) |

| Absorbed energy (machines with 8-mm strikers) | SRMs 2093, 2562, 2097, 2564, and 2099* | Self-verification (8-mm strikers, 21 °C and -40 °C) |

| Absorbed energy (machines with 2-mm strikers) | SRMs 2197, 2198, and 2199* | Self-verification (2-mm strikers) |

| Dynamic Force | SRMs 2112 and 2113 | Self-verification (force and energy, 8-mm strikers) |

| Absorbed energy and dynamic force (KLST-type miniaturized specimens) | SRMs 2216, 2218, and 2219 | Self-verification (force and energy) |

| Absorbed energy (RHS-type miniaturized specimens) | SRMs 2237, 2238, 2239 | Self-verification (energy) |

*WARNING: The steel currently used by NIST for the production of super-high energy reference Charpy specimens tends to leave debris on the machine anvils when the specimen is dragged by the swinging hammer. Accordingly, it's extremely important to accurately clean the anvils after each test, by scraping them with a razor blade or a similar sharp tool, until both anvils feel "smooth" to the finger. If anvils are not properly cleaned, absorbed energy may be artificially increased due to excessive friction, and the machine may fail its indirect verification at the super-high energy level. NOTE: in most cases, super-high energy specimens will not fracture completely when tested.

The analysis of the indirect verification tests depends on whether the SRMs are provided with NIST- or Self-Verification. Please find the details for the particular SRM tested (above).

Proficiency Testing (PT):

| NIST PT Analysis | Link to web page | |

Major Accomplishments

Since 1989, the NIST impact verification program has provided more than 20 years of service to manufacturers and consumers and currently certifies eleven SRMs that underpin quality control testing of impact toughness for structural steels. We provide SRMs to verify the measurement of absorbed energy at three energy levels: low energy (14-20 J); high energy (88-136 J); and super high energy (176-244 J), for both 8 mm and 2 mm strikers. We also provide two SRMs that are used to verify the measurement of maximum force in a Charpy impact test, and SRMs for the verification of small-scale impact machines (miniaturized Charpy specimens).

The Charpy program supplies approximately 5,000 units per year to customers worldwide. Typically, we evaluate and report on approximately 1,400 verification tests per year. We are available to our customers by email, fax or phone (1,500 contacts per year), and continually update our customer website and database to improve customer interactions. Most recently, the program has gone paperless, improving the already short turnaround time for our post-test evaluation to same-day service. For a 2017 presentation which outlines the history of the Charpy test, as well as the operation of the NIST Charpy Machine Verification Project, navigate to the Presentation (PDF).

We recently added a means for our customers to obtain a proficiency test result for their impact test. When a customer purchases a set of SRMs, the data from all NIST verification tests for that lot are made available (for lots that have at least 50 sets of results available). Customers can compare their test results to this compiled data, giving them an alternate means (aside from meeting ASTM or ISO requirements) to evaluate the performance of their machines, and the relative performance of multiple impact machines within their organizations. This information supports efforts by industry to achieve or maintain quality system certification through ISO or other standards bodies.

NIST maintains leadership positions in ASTM and ISO standards committees and has long been active in improving impact testing standards both in the U.S. and around the world. We maintain an extensive database of customer data in order to further improve measurement accuracy and support our ISO and ASTM activities. For example, we published a guide on uncertainty analysis for Charpy tests that offers users a full explanation of the uncertainty associated with the NIST reference specimens and the customer's verification test.

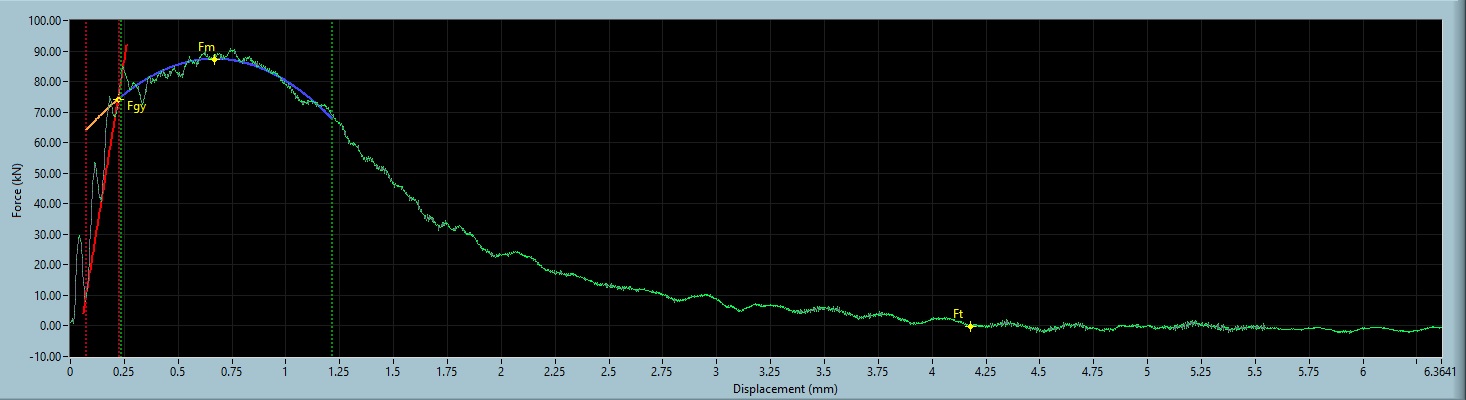

We are currently working with several national metrological institutes (NMIs) to develop an approach to SRM certification that reduces the bias among the NMIs. Our focus is on standardizing the design of instrumented strikers to provide comparable force-displacement data across all types of Charpy machines and achieving a true dynamic calibration procedure for instrumented Charpy strikers. If successful, absorbed energy measured under the instrumented impact curve will be traceable to force and time, linking the measurement to more fundamental quantities (see an example of instrumented curve below). This approach, like the current approach of measuring the energy absorbed from a pendulum swing (in Joules), has many practical issues that will need to be addressed - primarily related to friction and vibrational components of the absorbed energy. However, we see this as the future direction of impact testing and the best hope for establishing an international scale for measuring absorbed energy that can help to reduce bias among NMIs.

Additional Technical Publications

Additional Technical Details

Staff from the Statistical Engineering Division (SED) have been involved in the Charpy Machine Verification Program since NIST acquired the program from the U.S. Army in 1989. SED staff have proposed new verification limits for variation based on: an F-test, a range rule, and variation in the production lot, because the verification limits stated in ASTM E23 are somewhat arbitrary and there is no limit to variation in a set of five specimens. We have developed an uncertainty procedure for the reference value as well as guidelines for computing uncertainty for customer measurements in the Recommended Practice Guide, "Computing Uncertainty for Charpy Impact Machine Test Results".

A proficiency testing service is also available, so that customers can compare their test results to those of other customers that have tested specimens from the same lots. SED staff are responsible for providing appropriate statistical analyses for this service.

In 2014, C. McCowan (ACMD), R. Santoyo (ACMD), J. Splett (SED), and J. Wang (SED) won the Department of Commerce Silver Medal Award for excellence in customer service.

In 2022, E. Lucon (ACMD) and R. Santoyo (ACMD) won the NIST Judson C. French Award for "Outstanding Customer Service by Creating a Digital Verification Program for Charpy Impact Test Standards Involving > 1,900 Customers Per Year in 60 Countries."

Associated Products

Charpy Project Summary (PDF)