Summary

Straw detectors are a new concept in position-sensitive neutron detectors recently developed by Proportion Technology Inc. The detectors are especially valuable in large-area imaging applications and scattering instruments, and are being installed at the Spallation Neutron Source (SNS) at Oak Ridge National Laboratory. The atomic thickness of boron carbide deposits on the individual tubes is critical to the efficiency of the overall detector. Neutron Depth Profiling (NDP), a nondestructive metrological technique, played a critical role in optimizing the performance of these novel high-resolution neutron systems.

Description

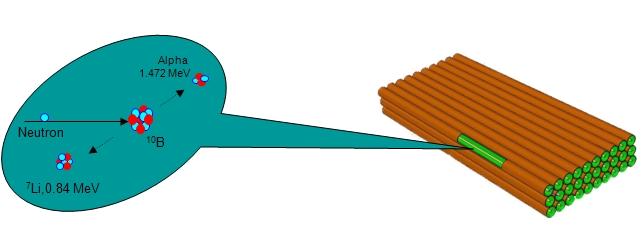

Neutrons are not easily detected with high resolution and good efficiency. Consequently, high-quality neutron detectors remain a challenge to manufacture. A few nuclides such as He-3, Boron-10, and Li-6 are commonly used to convert impinging neutrons into an electrical pulse that post-processing electronics can cope with. The two most commonly used neutron position-sensitive detectors are a 3He proportional counter and a ZnS/6LiF scintillator. The first has, perhaps, the highest detection efficiency, but is costly to make, and the resolution is relatively poor. The latter has better spatial resolution, but suffers as an optimal solution as the afterglow in a scintillator can last for up to 10 microseconds, making it unsuitable for any high count-event application. The neutron-active surface of a straw detector is sputter coated with enriched boron carbide (10B 4C). In operation, two highly energetic charged particles are generated by neutron capture. One of those two particles must escape the deposit and ionize gas within the hollow straw. A pulse signal is read out via the suspended wire running through the center of the straw. Many straws are close packed into a 2D array that forms the large-area neutron position-sensitive detector. (Figure 1)

The balloon illustrates the boron-10 reaction. The atomic thickness of the 10B4C coating applied to the straw strongly influences detector efficiency and overall performance. The 10B4C must be sufficiently thin to permit the efficient escape of one or the other reaction product emitted upon each neutron reaction with a 10B atom. Otherwise, the event is lost in self absorption. Furthermore, if the film was too thick, remaining neutrons could not continue along their trajectory to the next straw, leading to another inefficient loss. Obviously, the accurate determination of boron depth distribution (stoichiometry) and total mass – not linear thickness - of this thin (≈ 1μm) lining is critical in the manufacture of straw elements. The required metrology is readily achieved using NDP. Sample coupons were selected representing material along the length and width of the 10B4C deposition chamber. NDP spectra were then determined from each sample; three spectra are overlaid and presented in Figure 2 illustrating the variations in the atomic thickness of boron found. NDP results revealed that the masks used in applying the film yielded a smoothly varying thickness in coating across the chamber (see Figure 3). Using the metrology provided by NDP, a practical and reliable approach to compensate the deposition mask was provided as determined in subsequent production runs.

Major Accomplishments

- Completed the determination of variations in boron mass deposits on foils

- Mapped variations of boron mass across deposition chamber for quality control and calibration

ASSOCIATED PUBLICATIONS

1. Simons, D. S., Downing, R. G., Lamaze, G. P., Lindstrom, R. M., Greenberg, R. R., Paul, R. L., Schiller, S. B., and Guthrie, W. F., "Development of certified reference materials of ion-implanted dopants in silicon for calibration of secondary ion mass spectrometers," Journal of Vacuum Science & Technology B, 25, 1365-1375 (2007).

2. Lamaze, G. P., Chen-Mayer, H. H., and Soni, K. K., "Analyses of thin films and surfaces by cold neutron depth profiling," Applied Surface Science, 238, 108-112 (2004).

3. Chen-Mayer, H. H., Lamaze, G. P., Coakley, K. J., and Satija, S. K., "Two aspects of thin film analysis: boron profile and scattering length density profile," Nuclear Instruments & Methods in Physics Research Section A-Accelerators Spectrometers Detectors and Associated Equipment, 505, 531-535 (2003).

4. Coakley, K. J., Chen-Mayer, H. H., Lamaze, G. P., Simons, D. S., and Thompson, P. E., "Calibration of a stopping power model for silicon based on analysis of neutron depth profiling and secondary ion mass spectrometry measurements," Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions with Materials and Atoms, 192, 349-359 (2002).

5. Chen-Mayer, H. H., Lamaze, G. P., and Satija, S. K., "Characterization of BPSG films using Neutron Depth Profiling and neutron/x-ray reflectometry," Characterization and Metrology for Ulsi Technology 2000, International Conference, 550, 407-411 (2001).

6. Chen-Mayer, H. H. and Lamaze, G. P., "Depth distribution of boron determined by slow neutron induced lithium ion emission," Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions with Materials and Atoms, 135, 407-412 (1998).