Summary

This project is tasked with enabling accurate nanomechanical property measurements on materials through calibrations and standards. Our goal is to develop standard reference materials and quantitative, reproducible, measurement methods and protocols for atomic force microscopes, to enable accurate dimensional, force, and material property measurements at the nanoscale.

- Atomic Force Microscopes (AFMs) are the most common scanning probe instrument, with tens of thousands of AFMs in use in virtually every materials research and development laboratory worldwide.

- Cantilevers used in AFM to interrogate surfaces are very small – the width is less that the width of a human hair.

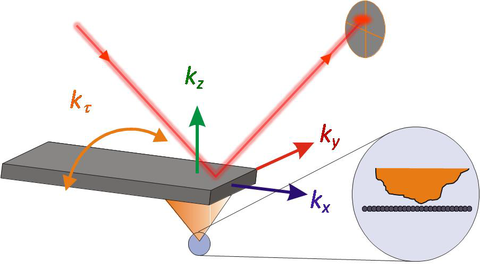

- The interaction between the cantilever probe tip and a surface is usually measured using a laser beam reflected from the back of the cantilever. Sub-nanometer cantilever deflections can be measured.

Description

The Nanomechanical Properties Group has expertise in a wide variety of SPM techniques, especially atomic force microscopy (AFM); however, the main research thrust for the Group’s standards project area deals with accurate cantilever stiffness calibration and the use and development of AFM methods for measuring the nanomechanical properties of surfaces.

Cantilever Stiffness Calibration

- Laser Doppler vibrometry thermal cantilever calibration

- SRM 3461 - Standard Reference Cantilevers for AFM Spring Constant Calibration

- Standards participation (VAMAS)

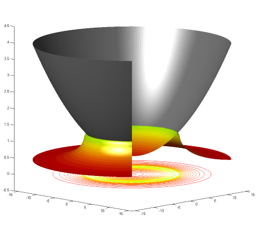

The cantilever stiffness calibration effort is spearheaded by the use and development of the laser Doppler vibrometry cantilever thermal calibration method as a means of accurately determining the stiffness of AFM cantilevers. This instrument, housed 12 m underground in our Group’s clean room facility is capable of making some of the most sensitive and accurate AFM cantilever stiffness measurements available. It provides the technical underpinning for complementary Group efforts in AFM standards and measurement method developments.

Impact and Customers:

- A broad spectrum of industries, government agencies, and academic institutions use scanning probe instruments to develop, characterize, and manufacture products from ceramics, metals, polymers, and semiconductors.

- Calibrating delicate measurement tools such as AFMs is difficult: at small length scales, the forces that affect probe-material interactions, and their relative magnitudes, are often unknown, but are certainly dominated by surface effects.

- Currently, the lack of SI-traceable stiffness calibration standards hampers progress towards making AFM force measurements quantitative; such measurements can be precise, but there is an incomplete understanding of accuracy.

Major Accomplishments

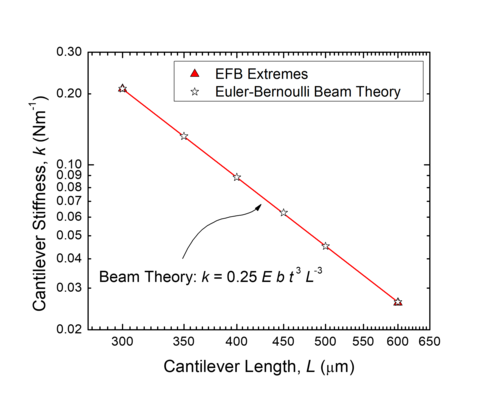

A series of extremely uniform prototype reference cantilever arrays were created that can be used to calibrate the spring constants of atomic force microscopy cantilevers and other micromechanical structures. Nominal spring constants were estimated to be in the range of 0.02 Nm-1 to 0.2 Nm-1. Resonance frequency measurements were used to assess the uniformity of devices from different portions of a silicon-on-insulator wafer, and from different processing batches. Variations of less than 1% (relative standard deviation) in resonance frequency attested to the high degree of uniformity achieved. Independent calibration of cantilevers in an array using an electrostatic force balance indicated that the actual spring constants ranged from 0.0260 ± 0.0005 Nm-1 (±1.9%) to 0.2099 ± 0.0009 Nm-1 (±0.43%). The results confirmed the feasibility of creating uniform reference cantilevers and calibrating them using an SI-traceable technique, making these devices excellent candidates for small force calibration standards for AFM. An SRM production batch is currently in process.

Agreement between stiffness measurements and models

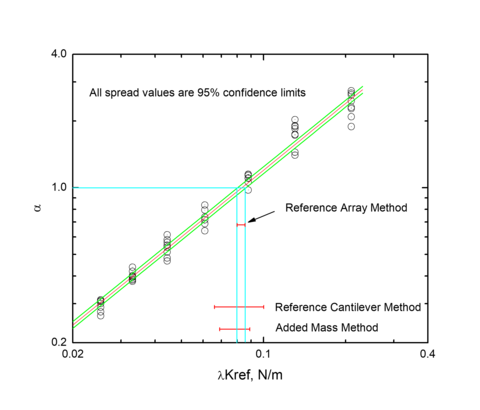

A method for calibrating the stiffness of AFM cantilevers was developed using the prototype reference cantilever array. A series of force-displacement curves was obtained using a commercial AFM test cantilever on the reference cantilever array, and the data were analyzed using an Euler-Bernoulli model to extract the test cantilever spring constant from linear regression fitting. The method offers improvements in precision over the reference cantilever method (factor of five) and the added mass calibration method

(factor of three) that are currently used for AFM calibration.

Project Summary (PDF)