Summary

Our objective is to support the efforts of the US automotive industry and its suppliers to incorporate advanced lightweight materials for improving fuel economy and lowering emissions while maintaining safety (i.e., crashworthiness) by developing foundational measurements, test methods, and standards for characterization of complex, multiaxial, multi-strain-path, and high-strain-rate material properties and behavior. With this knowledge, the US automotive industry will be able to transition to new advanced and lightweight materials more easily, as more accurate data and material models will lead to more accurate die designs, reducing die tryouts and new model development costs.

Description

The US auto industry spends $600M per year fixing and tweaking forming dies that do not make correct parts. The primary reason that the dies are inaccurate is that the computer models of the dies utilize materials models that are inaccurate. Upon surveying our industrial partners, we determined that a key NIST role in addressing this problem lies in developing new mechanical testing methods and metrology, and also developing a fundamental understanding of the interplay between multiaxial strain behavior and sheet microstructure.

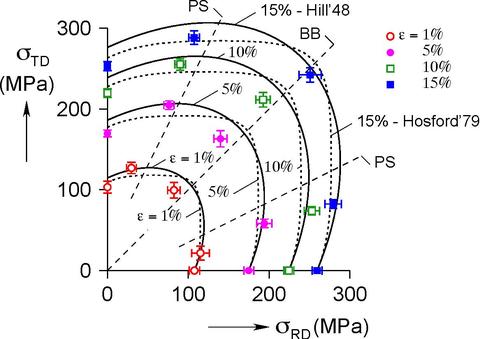

We are developing a technique where the sheet’s stress-strain response can be measured along non-linear multiaxial paths. This provides unique data on how the multiaxial flow surface changes with plastic strain, and this can be used to modify materials models used by industry. Concurrently, we also measure the evolving crystallographic texture of the sheet and the surface roughness, to develop a microstructural understanding of the materials' deformation response.

Major Accomplishments

The initial shape of the surface closely approximates an ellipse, as predicted by most plasticity models for forming. However the balanced biaxial strain path results in unequal biaxial stresses, contrary to the plasticity models. At the highest strains the biaxial stresses become balanced. Also of note is that the plane strain behavior is not symmetric between the rolling and transverse directions.

Yield locus evolution

Project Summary (PDF)