Summary

The flow of polymer composites via injection molding, spraying or spreading on surfaces is crucial to polymer composite manufacturing. For single-phase liquids, there is already a very wide range of flow properties possible, dependent on molecular interactions, temperature, and other variables. For polymer composites, adding particles of various shapes, with varying (and tunable) interactions with each other and with the matrix fluid, makes the potential intrinsic rheological problem even more complex. In industry, the polymer composite material's rheological properties are input into commercial CFD-based models. However, it remains a great challenge to predict the rheological properties of complex fluids like polymer composites at the inclusion meso-scale, by which is meant a scale that is in-between fluid molecular structure and composite material end-use.

Description

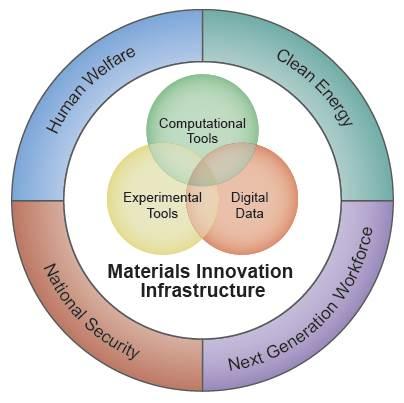

The goal of this MGI project is to establish an interactive database, generated by sophisticated modeling, such as dissipative particle dynamics and smooth particle hydrodynamics, to compute the rheological properties of polymer composites, where interaction among inclusions, inclusion particle shape, inclusion particle surface modification, and matrix fluid properties are inputs. The focus is particularly on non-spherical inclusions making up the polymer composite. The inclusion size scale is arbitrary. The database will serve as a meso-scale tool to aid industry in their use of commercial software to design new materials, improve quality control in manufacturing, and help reduce time from the initial idea and design to production of goods. We plan to integrate this interactive database with other MGI tools, operative at other length scales, being created and optimized in the NIST polymer composite pilot project.

Major Accomplishments

See http://concrete.nist.gov/CREME.html for modeling examples in concrete rheology.

Other references include:

N. S. Martys, M. Khalil, W. L. George, D. Lootens, P. H'ebraud, Stress propagation in a concentrated colloidal suspension under shear, Eur. Phys. J. E 35:20 (2012).

N. S. Martys, D. Lootens, W. L. George, and P. H'ebraud, Contact and stress anisotropies in start-up flow of colloidal suspensions, Physical Review E 80, 031401 (2009).

C. F. Ferraris and N. S. Martys, "Concrete Rheometers," in Understanding the Rheology of Concrete, pp. 63-82 Woodhead Publishing Limited (2012).

C. F. Ferraris, N. S. Martys, and W. L. George, Development of Standard Reference Materials for Cement-Based Materials, Accepted for publication and will appear in a special issue of Cement & Concrete Composites Journal, 2013.

The essential nature of the polymer composite problem – non-Newtonian rheology and heterogenous microstructure over multiple length scales – is identical to the concrete rheology problem. Experience gained in modeling concrete rheology for non-spherical inclusions will aid in the polymer composite problem.

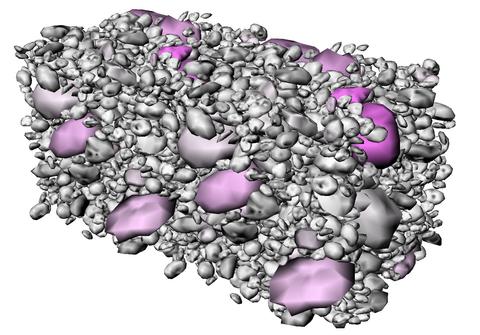

Dense packing of real sand and rock particles for simulating the rheology of a concrete. Smooth particle hydrodynamics is used to compute all the particle-particle and particle-fluid interactions under an applied shear strain.

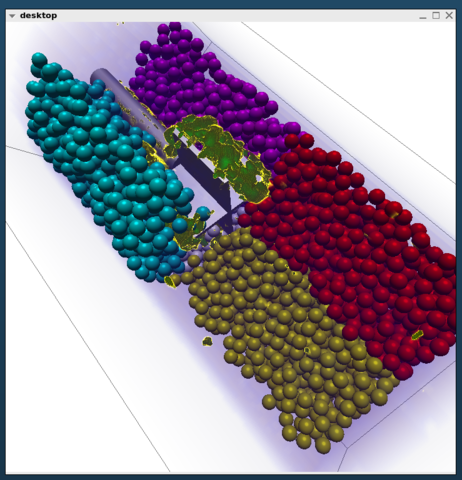

Smooth-particle hydrodynamics simulation of a vane rheometer used to measure the rheological properties of complex composites like concrete and polymer composites where the inclusions are too large for a parallel-plate geometry. In this case, the inclusions happen to be spherical.

Our simulations use two computational methods for simulating fluid flow, Dissipative Particle Dynamics (DPD) and Smoothed Particle Hydrodynamics (SPH). These methods are both mesh-free Lagrangian methods in which the fluid is represented as a set of mesoscopic particles that move in a continuous space, with each particle accounting for the microscopic particles in a small volume of the fluid. This approach is capable of modeling the flow of non-Newtonian fluids commonly used in the building industry (i.e. shear thinning and shear thickening behavior found in mortars and concrete). Modeling suspensions with inclusion sizes varying several orders of magnitude (such as concrete) is beyond the capabilities of any existing computer. Here we have developed a multi-scale approach that allows one to characterize fluid behavior associated with the typical size of its inclusion (i.e. mortar can be thought of as a cement paste with sand as the typical sized inclusion) and then use those fluid properties to serve as the matrix fluid for suspensions with larger inclusions (i.e. concrete can be thought of as composed of a mortar fluid with large aggregates/rocks as the typical inclusion). Our simulation models are currently being applied to the development of Standard References Materials (SRMS) for rheological measurements of mortar and concrete.

Standard reference materials for cement paste, mortar, and concrete rheology measurements. Standard test methods and computational algorithms for characterizing particle shape statistics.