Summary

Our goal is to develop and promote the adoption of small-volume rheological methods for complex fluids including bio-fluids, suspensions and polymers, where small volume capability is advantageous because it is the natural length scale, the sample size availability is small, or the technique is more sensitive.

Description

One way to develop small-volume rheology methods that we have used successfully is to start with existing concepts and geometries of rheometry and to then "think small." This approach ensures that we are measuring fundamental materials properties rather than quantities that are experiment and geometry specific. Examples include:

- Development of a multi-sample capillary rheometer that is based on a traditional rheometer but uses approximately 1000 times less material. Links: J Rheol, Chem Eng Sci.

- Development of nano-scale Coulter counters which can measure the properties of individual nano-particles and the effects of confinement on polymer flow. Link: Nano Letters.

- Development of a dynamic rheometer for solution characterization that uses traditional oscillating parallel plates, but is constructed in a MEMS platform. Link: Lab Chip.

Another way is to start with small scale phenomenology (such as flow in a droplet) and then develop a theory that connects to rheological parameters:

- Thus is born a new interfacial rheology method, using micro-fluidic devices that generate well-defined flow fields to probe interfacial properties such as interfacial tension and interfacial viscosity. Links: New J Phys, Adv Mat, Soft Matter.

Research Opportunities:

National Research Council (NRC) Fellowships

- Microfluidics for characterization of complex fluids

- Modeling of complex fluids in microrheometry

- "On-a-chip" polymer processing laboratory

- MEMS rheometry

- Other NRC research opportunities are searchable

- See here, for a list of specific research objectives and questions.

Major Accomplishments

- MEMS rheometer: Unique capability of direct microscopic sample visualization and multi-frequency rheometry of nL samples. Links: Techbeat; Lab-on-a-Chip

- Polymer microfluidics: We developed a multi-sample capillary rheometer that is based on a traditional rheometer but uses approximately 1000 times less material.

- Simple fabrication; complex flow and mixing possible.

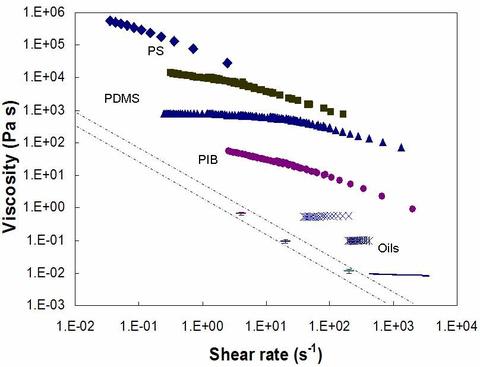

- Multi-rate viscometry (spanning 5 orders in rate and 8 in viscosity). - Droplet-based interfacial characterization:

- By measuring dynamic interfacial tension; surfactant kinetic sorption coefficients have been determined.

- a new rheology measurement that captures both interfacial shear and dilatational properties. These characteristics have required separate measurements until now. This work applies to emulsions, which have important industrial applications in numerous fields from drug to food manufacturing, and may lead to better guidelines for preparing and stabilizing emulsions.

- We plan to extend this work to protein solutions and with capabilities to explore the relationship between interfacial rheology and aggregation.

Polymer microfluidics

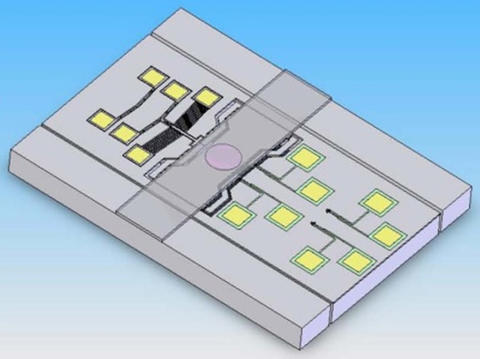

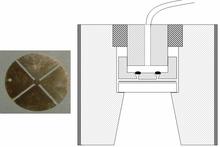

We have developed a multi-sample micro-capillary rheometer,M2R,which is capable of measurements over a broad range of temperatures, viscosities and shear rates. The instrument is inherently simple as the flow is generated by external gas pressure and the shear rate is measured through optical tracking of the flow front. In the current implementation, the required mass of each sample is approximately 20 mg, which is significantly less than traditional rheometers, further it measures four samples simultaneously. The device shown above contains no moving parts and the flow geometry is simply defined by slits cut into standard grade stainless steel shims. We find excellent agreement between the results obtained with the M2R and those from standard rheometers.

This figure shows viscosity measurements that cover a range from high temperature polymer melts down to very light room temperature oils. In order to conduct measurements at viscosities below ~1 Pa s, we must account for the capillary forces which act to pull the fluids into the flow channels. We successfully measured these forces by removing the input gas pressure and by tilting the device so that a fluid in one slit travels upwards while an identical fluid in another flows downwards,at a greater rate. From the difference in flow speed, we can measure the capillary force and thus correct our data. We also demonstrate procedures for correcting data for shear-thinning and entry/exit flows. This instrument will be particularly useful in cases of multiple samples, limited material quantity, when flow heating is unacceptable and when optical access is useful. More generally, the techniques employed here pave the way for the development of polymer melt microfluidics. We envision that mixing, processing and measurement operations can all occur in these devices.

Interfacial rheology

our new droplet-based method to measure the viscoelastic properties of interfaces measures the two fundamental modes of interfacial deformation: dilation and shear. As the name indicates, the former involves changing local interfacial area, whereas the latter is at constant area. Both types of motion always occur, and different material properties are associated with each. Dynamics of sorption have also been determined by measuring interfacial tension with time. The droplet-based approach enabled additional material constants to be determined, since drop size can be adjusted and thus change the limiting mass transfer processes.

Protein and particle rheology

This effort will start at the end of this year. We will initially put together a high-accuracy microfluidic viscometer to measure small solution volumes and assess solution stability. Improved temporal resolution will measure fluctuations in viscosity and thus function as a rough particle counter.

MEMS rheometer

A proof of concept study was completed. Future needs are easier sample loading and real-time measurement of stage position, so that data may be gathered more efficiently and accurately.

Complex Fluid Formulation Dialog

An international dialog on state-of-the-art measurement methods and emerging needs in the formulation and manufacture of complex fluids.

Project Summary (PDF)