Summary

MSED is developing methods to statically couple finite element modeling (FEM) to atomistic molecular dynamics (MD)1. Compared to non-hybrid approaches, this methodology has the advantage of incorporating both long range interactions and atomistic effects into the simulations when modeling deformations at the nanoscale.

Description

MSED, as a part of the MGI effort within NIST, is developing a multiscale modeling schema, statically coupling finite element modeling (FEM) to atomistic Molecular Dynamics (MD)1. This methodology allows a far more realistic representation of physical phenomena than that obtained by applying each method individually. The advantage of this hybrid approach is that it incorporates both long range interactions and atomistic effects into the simulations.

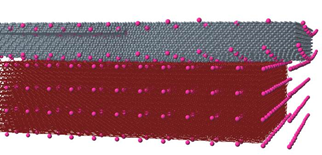

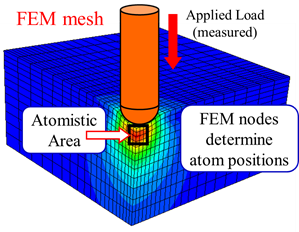

An important application of this methodology is quantitative modeling of nanoindentation. In this work, the anisotropic elastic indentation of a single-crystal Ni substrate by a deformable diamond indenter is initially simulated using FEM. This allows for a very large (micron scale) simulated system that directly and accurately captures the long range elastic deformation caused by the nanoindentation. The relaxed FEM node positions are saved at each, successive, indentation step. These positions are then interpolated to determine the initial atomic positions for the MD simulations, therefore incorporating all of the information about the elastic deformation into the atomistic modeling. An individual MD simulation is run for each FEM indentation step (semistatic procedure), therefore avoiding the need for using extremely high (very unrealistic) indentation rates that are unavoidable in MD-only simulations. Using atomistic MD means that interatomic forces are used to determine the relaxed configuration of the system. As a consequence, both temperature effects and the possibility of plastic behavior, to the point of structural rearrangement, are included in the modeling. Among the many advantages of this methodology is the ability to produce more realistic (i.e., in better agreement with experimental findings) results while using much smaller system sizes than equivalent MD-only simulations.