NIST’s Ultra-small, Shape-shifting GEMS Offer an Easier and Cheaper way to improve MRI Imaging

Microscopic magnetic probes that change shape in response to their environment may greatly enhance magnetic resonance imaging (MRI). However, producing the probes, which are still experimental and have not yet been used in humans, has required access to a cleanroom and expertise in nanofabrication, limiting their widespread use.

Now, researchers at the National Institute of Standards and Technology (NIST) have taken these shape-shifting probes, known as geometrically encoded magnetic sensors, or GEMS, a step further by unveiling a novel fabrication method that is not only faster and cheaper but eliminates the need for specialized instruments.

The scientists reported their work online Dec. 19 in ACS Sensors.

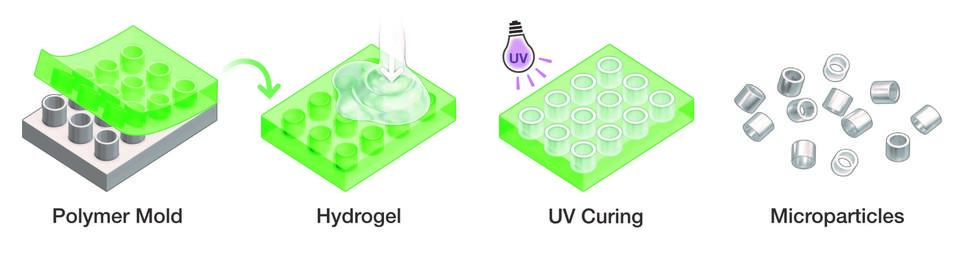

Instead of building the tiny probes layer by layer in a nanofabrication facility, the team constructed them using a precision master mold. This technique allows researchers to make GEMS in their own laboratories using inexpensive materials and readily available equipment.

NIST scientists Gary Zabow and Samuel Oberdick, and their colleagues, focused their efforts on building GEMS shaped like tiny hollow cylinders because that shape can be easily fabricated with a mold. For their master mold, the scientists constructed an array of hollow cylinders made of hard silicon, each only about 100 micrometers in diameter --- about ten times larger than a red blood cell.

The team then demonstrated how researchers with such a master mold could complete the multi-step fabrication process. First, the scientists made a soft-mold “negative” of the master by pouring a liquid polymer on top of the hard silicon mold, allowing it to solidify, and then peeling it off. This created a pliable mold with an array of cylindrical hollow cavities.

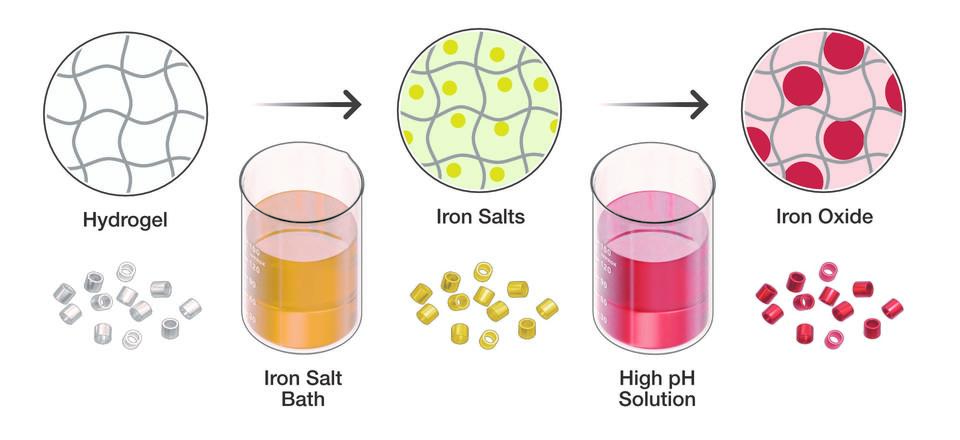

In the next step, the scientists filled each cavity with a liquid precursor to a hydrogel--a network of cross-linked polymers that can absorb large amounts of water. The hydrogel, which had been engineered to shrink or swell in response to changes in acidity or other properties in its microenvironment, is a key component of the GEMS. Engineered hydrogels are inexpensive and easy to make.

After hardening the hydrogels by exposing them to ultraviolet light, the NIST team turned them out of their soft mold, similar to popping ice-cubes out of a silicon tray. The cylindrical hydrogels were then immersed in a bath of iron salts and transferred to a basic solution, which converted the iron salts absorbed by the hydrogels into magnetic oxide particles.

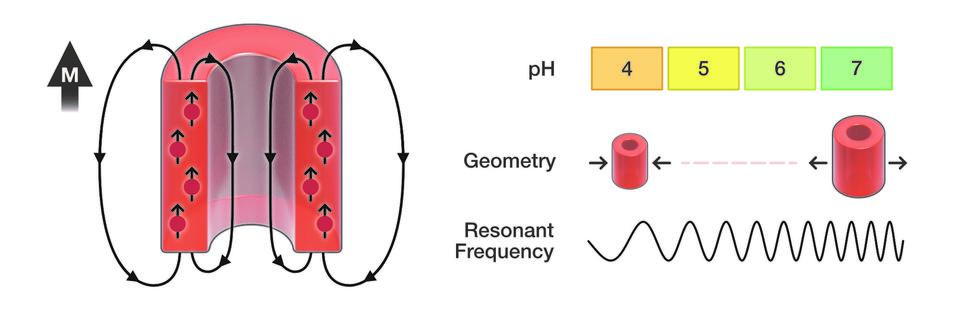

The strength of each hydrogel’s magnetic field has a direct bearing on MRI, which manipulates the tiny magnetic fields of protons to image internal structures in the human body. Protons behave like spinning magnetized tops, each initially pointing in a random direction.

An MRI machine aligns the magnetic field of the protons with its own strong magnetic field and then disrupts that alignment by tickling the protons with a pulse of radio waves at a resonance frequency that causes the protons to alternately “relax” into their original states and then become aligned again. As the protons cycle back and forth between the two states, they emit radio waves, which are translated into MRI images.

Meanwhile, the hydrogels change their shape in response to changes in local conditions, and as a result their magnetic field strengthens or weakens.

The changing magnetic field of the GEMS shifts the resonance frequency of the protons that lie in or near the probes. By measuring the shift, MRI can detect how the GEMS have altered their shape in response to a specific property in their local environment.

GEMS that are built with the soft-mold process can be tailored to change their shape to a host of environmental properties, allowing researchers to use the probes to explore a range of biomedical conditions, Oberdick said.

Paper: Samuel D. Oberdick, Stephen J. Dodd, Alan P. Koretsky, and Gary Zabow. Shaped Magnetogel Microparticles for Multispectral Magnetic Resonance Contrast and Sensing. ACS Sensors, Published online Dec. 19, 2023. DOI: https://doi.org/10.1021/acssensors.3c01373