Summary

Neutron imaging continues to play a key role in elucidating the role of water in proton exchange membrane fuel cells (PEMFCs) as highlighted by two projects with Los Alamos National Lab.

Description

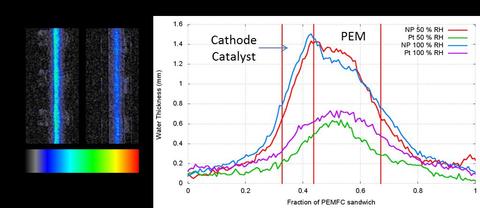

Comparison of PANI catalyst to a thick Pt on Carbon catalyst at open circuit voltage. The ling plot shows that the PANI catalyst (labeled NP) is hygroscopic at the catalyst layer/membrane interface.

Two of the most critical challenges to commercialization of PEMFCs for automotive applications are the cost of the Pt used in the catalyst layers and the system lifetime. Because the oxygen reduction reaction in the PEMFCs is slow and at low temperatures, finding a suitable replacement for Pt has been incredibly challenging. A recent development of a non-precious metal catalyst that uses iron functionalized by nitrogen starting with a precursor of polyanilane (PANI) has shown remarkable performance. However, electrochemical measurement indicated that this thick catalyst layer may suffer from flooding, a condition that occurs when liquid water clogs the catalyst layer. Two samples were tested, a PANI catalyst and a Pt on carbon catalyst of similar thickness of the PANI. The neutron data shown in Figure 1 revealed that the flooding in the PANI catalyst was not due to the thickness but rather that the interface between the catalyst and membrane was hygroscopic, as evidenced by large amount of water uptake at this interface even when no current was being drawn.

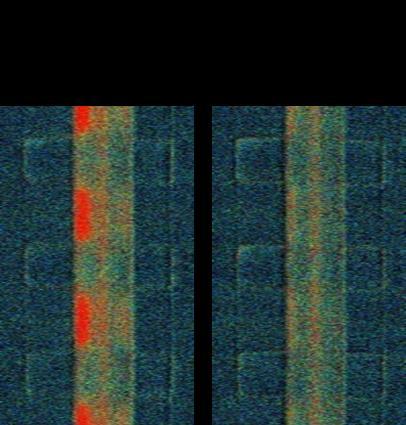

The lifetime of a fuel cell is affected by a myriad of factors, two of which include carbon corrosion of the catalyst layer and an increase of the hydrophilicity of the gas diffusion layers (GDLs) due to loss of PTFE. In the case of carbon corrosion, the degraded catalyst layer collapses, losing all its porosity and increases the internal resistance of the system. For a given operating current, the fuel cell operates at a lower potential, generating more waste heat which will dry the cell out. In the case of more hydrophilic GDLs, the product water maybe more likely to be held up at the interface with the catalyst layer and create a flooded condition. Several accelerated stress tests were conducted to rapidly degrade a cell and the neutron image data in Figure 2 showed that the primary change to the water transport in the fuel cell was the additional waste heat from the collapsed catalyst layer. Since it is known that the details of the GDL wettability strongly influence the water transport in the PEMFC, these studies are being further refined.