Newly Patented NIST Technique Creates Precisely Sized Nanocontainers Useful for Drug Delivery

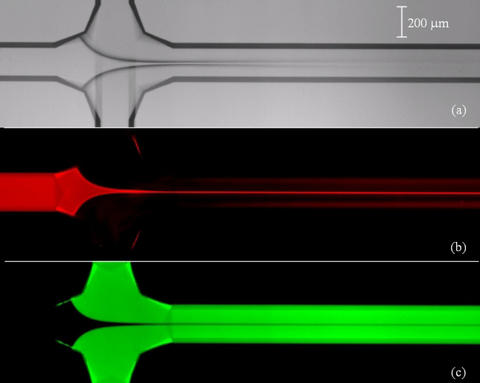

In a recently patented NIST method for making precisely sized nanoscale capsules, a stream of fluid (isopropyl alcohol) containing dissolved biomolecules (the building blocks for the capsules) is focused by streams of water on either side. Panel (a) shows a white-light image of the focused fluid stream, and (b) and (c) show fluorescent images of the stream. The red dye indicates the presence of lipid molecules, initially dissolved in isopropyl alcohol, and the green dye indicates the presence of water. Fluid moving through channels with a width of up to 200 micrometers, or millionths of a meter, can be focused to the point at which the dissolved biomolecules coalesce into nanocapsules with diameters in the hundreds of nanometers, or billionths of a meter.

What if doctors could deliver anti-cancer drugs directly to tumors without making patients sick? Bringing this dream of targeted drug delivery closer to reality for pharmaceutical manufacturers, researchers at the National Institute of Standards and Technology (NIST) have received a patent for a method to create precisely sized nanometer-scale capsules.

The NIST method employs microfluidics, the use of fluids at the microscopic level, to create precise nanoscale spherical capsules. Made of lipids, the kinds of biomolecules that also comprise fats, the spherical capsules are known as liposomes. Essentially, liposomes are simplified artificial versions of cell membranes, the outer coverings of cells. The inside of a liposome could hold drugs, and the outside could be coated with receptors that bind to specific cancer cells.

The method can produce liposomes with typical diameters of 100-400 nanometers, or billionths of a meter. This size range is useful for attaching to cells, whose size is typically 1 to 10 micrometers, or millionths of a meter.

Typical methods for making liposomes include pushing a lipid solution through a filter, a process that can lead to wide variations in the size of the resulting liposomes. Furthermore, the methods can be wasteful, and can result in large amounts of expensive drugs not being captured inside the liposomes and being discarded.

In the NIST technique, lipid material is dissolved in isopropyl alcohol. The resulting lipid-containing solution is then forced into a narrow channel and further constricted when it is squeezed by streams of water coming at it from multiple sides. Lipid molecules are repelled by water, so they clump together and coalesce into spherical liposomes. Adjusting the flow rate of the water can control the size of the liposomes that form.

"We have precision control over making liposomes and changing their size by dialing in flow rates," said Michael Gaitan, who works in NIST's Physical Measurement Laboratory.

Researchers could dissolve drugs or other molecules of interest into the water stream, Gaitan explained. Adjusting the concentrations of these molecules can determine the amount of the drug that ends up in the liposome, down to the single-molecule level.

This method, which has received interest in being licensed by companies, originally developed from basic research. Gaitan and collaborator Laurie Locascio were looking for ways to enclose individual molecules of interest in fluid-filled capsules to study their behavior in a liquid environment. Previous methods had anchored individual molecules in glass slides, which are rather unnatural environments, as opposed to the more cell-like environment of a fluid-filled liposome. Once this technique was developed, researchers were able to create a variety of liposomes of many useful sizes, and the potential drug-delivery applications became clear. The researchers were awarded a patent for this work late last year.

"This research and the resulting patent also have implications for the on-demand formulation of drugs in a way that's applicable to personalized or precision medicine," said Laurie Locascio, director of NIST's Material Measurement Laboratory.

"The reason that this patent is so fundamental is that this is a process patent," which is a more general form of patent, Gaitan explained. The method does not require a specific experimental configuration, but is a general approach that can be realized in many ways, he said.

Moving forward, researchers at NIST's Center for Nanoscale Science and Technology are continuing to develop this technique for more applications by creating capsules made of different types of nanoparticles. Size—and control—most definitely matter in nanotechnology. Being able to create precisely sized nanocontainers can open up many new applications, Gaitan said.

Those interested in licensing this patented technology are welcome to contact the NIST Technology Partnerships Office.