Summary

This project focuses on understanding the potential for nanoscale engineered materials to advance state-of-the-art spectroscopic techniques and foster the understanding of applications of new quantum phenomena for future real-world nanoelectronic, optoelectronic, and quantum computing applications.

Description

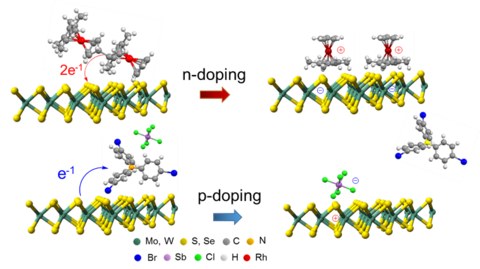

Schematic of interface engineering 2D materials.

This project focuses on manipulating nanomaterials, including weakly bonded van der Waals systems, and probing emergent phenomena in these nanoengineered systems to impact technologies such as nanoelectronics, optoelectronics, quantum sensing, and quantum computing. Developing processes to controllably tune interfaces, electrical, and optical properties is critical to achieving technological applications. Moreover, understanding the complex interplay between the structure and ultimate performance can provide valuable insight into the utility of novel nanoscale materials. Particular emphasis is placed on novel measurements of chemical, physical, and electrical properties to fully interrogate nanoelectronic systems and provide the measurement foundation for advanced manufacturing of innovative future applications. Several approaches are investigated, including developing chemical surface modification methods which enable controlling, tuning, and altering the electrical and optical properties of low-dimensional materials and understanding quantum confinement in solution-processed materials including 2D materials and perovskites.

The project focuses on understanding the factors that govern critical properties in devices building upon extensive expertise in molecular electronics foundations including the formation and characterization of molecular layers and fabrication and qualification of electrode-molecule-electrode junctions which feed into to a fundamental understanding of charge transport at molecular interfaces. Core competencies include developing surface functionalization and spectroscopic characterization approaches to accelerate the development and characterization of advanced nanoelectronic devices.

From a metrology perspective, this research examines the critical measurements of confined materials and the role that chemical functionalization and manipulation can play to passivate or enhance performance. We also explore device applications of modified materials to advance spectroscopic characterization and as test cases for the critical performance indicators of 2D-based devices. Systematic characterization of the resulting solution-processed thin-film quantum materials are necessary to understand the quantum, electrical, and optical properties of these thin-film semiconductors and develop the relationship between the microstructure and device properties.