In recent years, the physical damage done by pressure waves – such as traumatic brain injuries from explosives sustained by military personnel in the Middle East – has become an increasingly urgent public concern.

Although there are many dynamic pressure sensors in use by equipment manufacturers, testing laboratories, and military contractors, none of them provides measurements traceable to the International System of Units through a national standard. As a result, there is no way to judge the relative or absolute accuracy of the devices.

Such problems may not persist for long. NIST scientists are developing a national standard for dynamic pressure measurements. "Currently, all the dynamic sensors out there, whether they're for pressure, acceleration, or force, have no system of traceable measurements," says project scientist Kevin Douglass of the Sensor Science Division. "Similarly, military personnel are now being outfitted with pressure sensors for detecting blast waves. But it is not clear that measurements made by different vendors will agree. That's where NIST comes in."

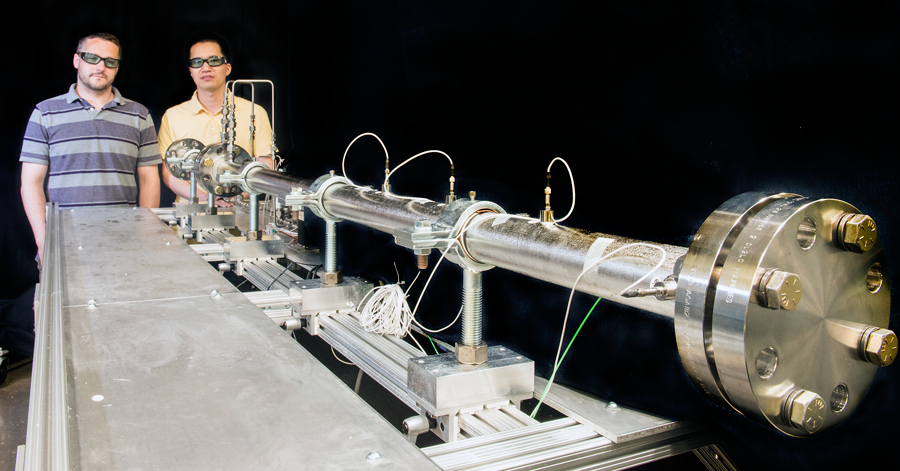

The scientists are at work on the first iteration of what will become a standard dynamic pressure research and calibration facility that will use a shock tube with fully controllable and reproducible conditions for creating dynamic pressure events.

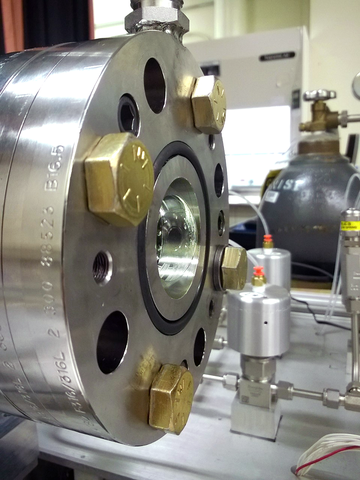

The current version is a 2.4 meter long tube with a 5 cm inside diameter filled with a gas. At one end, the pressure is raised to about six atmospheres and held in check by a diaphragm that can be ruptured on demand. (See photo below.) On the other end of the tube, in a controlled lower-pressure section, is a suite of commercially available piezoelectric pressure sensors.

Liu tested various materials including thin brass foil. So far, the best results come from polycarbonate films two 1000ths of an inch (0.05 mm) thick. In the next version of the shock tube, the diaphragm will be punctured by a focused laser beam.

The dynamic pressure sensors mounted to the shock tube typically employ piezoelectric systems that generate an electric charge when a passing pressure wave distorts the shape of the sensor's membrane.

"We'll be able to calibrate those sensors with the new shock tube configuration," says project scientist Zeeshan Ahmed. "The shock tube is used because it provides a near step-function change in pressure that is easily modeled. One approach is to assume the theoretical model provides the traceability, but we want to go beyond that. So we're developing a different, much faster measurement system that is based on spectroscopy."

The idea is to direct a laser beam across the tube, perpendicular to the direction of the shock wave. Photonic detectors will record the amount of laser light absorbed by the passing wave as a function of time – in effect, producing a series of fast snapshots to measure the passing pressure and temperature waves. The resulting spectrum depends on quantum properties of the gas molecules at different pressures and temperatures.

"Molecules react much faster than mechanical sensors," Douglass says. "And unlike piezoelectric sensors, the system we're developing can also measure temperature, allowing for precise characterization of the pressure wave. It measures absorption of the laser beam by trace amounts of carbon monoxide in a carrier gas such as argon or helium, which can be varied to get different thermodynamic properties." Currently the proof-of-concept sensor can make measurements on a time scale of a 100 microseconds. "We will improve that by a factor of ten," Douglass says.

When fully developed, the approach could provide pressure and temperature measurements whose accuracy depends only on well-known quantum properties of atoms. "Eventually we may be able to use 'NIST on a chip'-type sensors or fiber optic sensors and test those for temperature and pressure measures," Ahmed says. "If we can create sufficiently advanced sensors, we would be able to devise standards for commerce and science that would never have to come back for calibration."