Summary

Crystal Plasticity Modeling calculates multiaxial mechanical constitutive behavior by treating the sample as an interacting aggregate of single crystals that interact at their boundaries. The mechanical response is determined from a weighted average of the single crystal behavior. Our research has modeled deformation in aluminum and TRIP steels, and along linear and bi-linear strain paths. The best fit to experimental data is when the models consider long-range, multi-grain interactions and slip on secondary crystallographic systems.

Description

A robust multiaxial constitutive law is needed to predict stresses within parts formed from sheet metal to be able to compensate for such phenomena as elastic springback. Ideally, the constitutive law would not need to be "trained" using empirical mechanical property data alone, but would be able to compensate for changes in crystallographic texture of the incoming sheet.

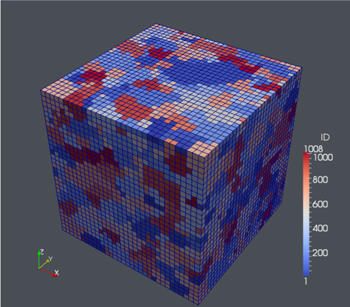

To this end, this project seeks to develop constitutive laws based on the initial crystallographic texture and uniaxial stress-strain data, predicting the evolution of the yield surface in multiaxial tensile space. Crystal plasticity modeling treats the material as an assemblage of interacting single crystals with an orientation distribution recreated from the measured texture. As plastic yield evolves, the crystals slip according to the Schmid factor of each system, and each grain rotates to maintain boundary compatibility. The constitutive behavior is then calculated as an average mechanical response of the aggregate.

Major Accomplishments

We have developed a model that captures quite well the multiaxial yield behavior of 5754 aluminum alloy sheet, and predicts the evolving texture fairly accurately. Discrepancies remain in predicting the transverse plane stresses, which coincidentally or not have never been directly measured before this study, and in how fast the crystallographic texture intensities change. Details on the work can be found in the papers linked to the right.