Taking Measure

Just a Standard Blog

3D Printing With Light: A Q&A With NIST's Callie Higgins

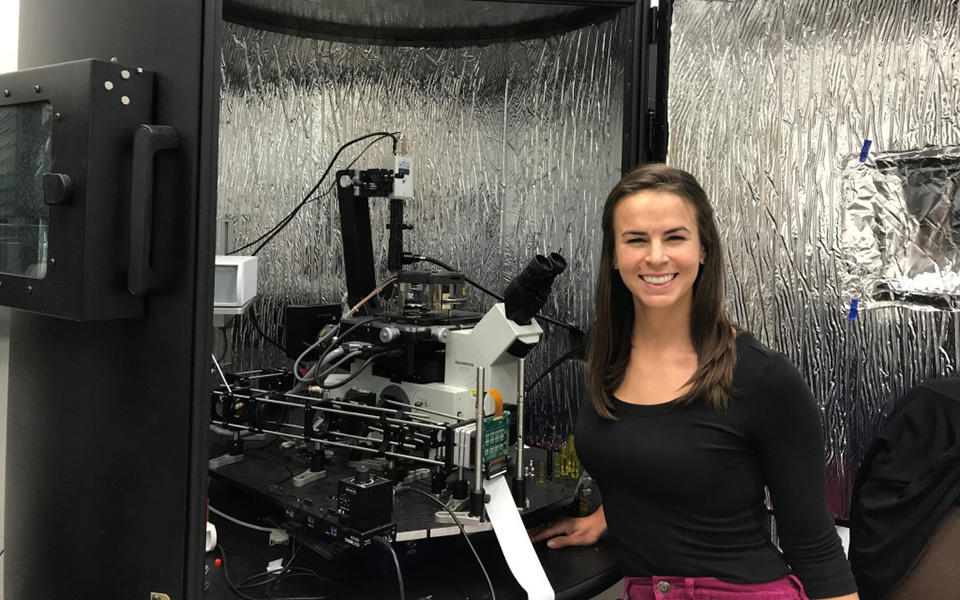

Callie Higgins with her hybrid atomic force microscope 3D printer.

Callie Higgins is a materials research engineer at the National Institute of Standards and Technology (NIST). She studies a special branch of additive manufacturing called vat photopolymerization, which uses light to solidify a liquid resin layer by layer into a 3D object. Callie is a finalist for a Samuel J. Heyman Service to America Medal in the Emerging Leaders category, which is awarded to federal employees under the age of 35 who have made important contributions early in their professional careers. The Samuel J. Heyman Service to America Medals are intended to highlight excellence in the federal workforce and inspire other talented and dedicated individuals to go into public service.

Tell us about your career path thus far. How did you get here?

I fell in love with physics at an early age and knew I wanted to study it throughout my life, so when I went to college and my classes only heightened this love, I realized graduate school was the best way to ensure I kept it in my life forever. In graduate school, I studied how light interacts with different materials and discovered an interesting technology called photopolymer additive manufacturing (PAM) that was starting to garner a lot of attention in industry and academia. PAM is a 3D printing technique that uses light to “cure” liquid plastics into solid materials with a range of light-controlled properties. I was fascinated by both the fundamental physics behind the technology and the high-impact applications it could have across society (think personalized, regenerative medicine and on-demand custom, large-scale manufacturing), but was a bit dismayed by the sheer lack of research publications discussing the fundamentals behind the printing process. However, I was so taken by the potential applications for the technology that I decided there was no time like the present, and if not me, then who else can I expect to help drive this field forward? So, I decided to devote my graduate studies, postdoctoral research and, ultimately, my career to ensuring my vision for this field comes to fruition.

What made you decide on a career in the federal government?

This is an interesting story because, to be honest, after I finished my graduate research, I was pretty tired of being in a dark room by myself for days on end (remember, these materials are photoreactive, so light can readily destroy an experiment) and didn’t think I wanted to pursue traditional research. However, I collaborated with two researchers, Jason Killgore and Frank DelRio, at NIST at the end of my Ph.D. who asked me to write a National Research Council Postdoctoral Associateship proposal that would enable me to work at NIST for two years and continue to develop the needed characterization tools to understand the PAM process. This was a difficult decision because I had an offer in hand for an industry position that would take me out of that dreaded dark, solitary lab, but I enjoyed both my work with them and the collaborative atmosphere so much at NIST that I decided to go out on a limb and at least submit a proposal. Fast forward to now, I was awarded that fellowship and realized during those two years that NIST is the perfect environment for me and my work to thrive due to its unique position at the intersection between academia, government and industry. I can not only readily grow the PAM research program at NIST with collaborators across the field, but also regularly work with those in industry to ensure our work continues to drive innovation in the field.

How did you get interested in 3D printing?

My graduate school group was working to develop light-patterned holographic materials (think heads-up display technology), which eventually evolved into light-cured additive manufacturing, where I built our first functioning 3D printer in the lab. I loved the hands-on work, but it was the potential applications of the technology (if the right fundamental research were completed) that had me sleeping in the lab to run time-lapse experiments. When you realize this technology has the potential to enable patient-specific artificial organs, your breath hitches a bit and you can’t help but dive into the research headfirst.

What are some of the problems with 3D printing that you’re trying to solve?

One of the fundamental challenges with PAM is the curing process whereby we use light to turn the resin from liquid to solid plastic. However, the liquid material must absorb light such that only the desired thin 2D slice of the 3D object is cured. This resin requirement leads the print to have non-ideal layered mechanical properties, making it subject to catastrophic failure. Common ways to overcome this are to heat or continue curing the material with light after initial manufacture. At NIST, we’re trying to characterize and understand the irregularities in the curing process at the voxel (or 3D pixel) and sub-voxel scale so that we can inform better printing and processing methods, while developing cutting-edge characterization tools to enable precise control of part properties in 3D (e.g., engineering parts to have soft and stiff regions to produce final parts that are both tough and able to stretch and bend, two properties that are normally inversely related).

Why do you think it is important to work directly alongside industry as you develop your measurement techniques?

It is imperative that we work with industry as we develop new characterization tools and materials because they are, ultimately, what drives this field forward from a niche technology into mainstream manufacturing. As a laboratory under the U.S. Department of Commerce, if we are not conducting research that is relevant and impactful to industry, then why are we doing it?

You’ve also been active networking with fellow young scientists in academia, federal labs and industry. Tell us about your work. Why do you think it’s important to have these networks?

Upon starting at NIST, I actively sought out early-career groups in which to get involved and pursue leadership opportunities. I was referred to the Postdoctoral and Early-career Association of Researchers (PEAR) by a colleague and upon joining, realized that there weren't very many opportunities for postdocs and early career Ph.D.s in the community to both interact with each other and with industry partners. I thought that collaborating with universities and other laboratories in Colorado to host a yearly summit to gather postdocs, early-career scientists and industry professionals would help promote the dissemination of cutting-edge research with industry partners and build ongoing local partnerships and collaborations between research institutions and industry professionals. So, in 2017, I founded the Front Range Industry and Postdoc Summit (FRIPS), which PEAR has now organized for three years with dozens of job opportunities arising from interactions at the summit and resulting in many more mentorship opportunities for attendees.

What’s next for you? What are your goals?

Ultimately, I want to do everything in my power to ensure PAM becomes a mainstream manufacturing technology and realize my (and so many others’) vision of harnessing it for regenerative medicine. While I believe NIST is uniquely positioned to drive innovation in this field (it is in the mission statement, after all) and would love the opportunity to stay at NIST permanently to grow our PAM project, at my core, I simply want to be in a position where I can continue to work with brilliant minds to ensure this field is impactful to society.

Do you have any advice for young women about pursuing a career in the sciences?

Throughout my years in the sciences, I developed a one-word mantra that I think many scientists would agree with: persevere. This is especially relevant to young women in the field for a host of reasons, one of them being that nearly all will be in a male-dominated field that will potentially affect how they conduct themselves and their research. Personally, I have encountered and needed to disarm many unfortunate stereotypes regarding women in science, which isn’t exactly written into the job description of a scientist. One tangible and actionable piece of advice I have is for them (and really anyone) to watch the documentary Picture a Scientist because it will, at the very least, help them recognize that they are not alone and there are many women across the sciences wading through these muddy waters with them.

Read Callie's honoree profile.

Read more about research involving Callie's work in our news story, "Nanocylinder Vibrations Help Quantify Polymer Curing for 3D Printing."

Related posts

Comments

A very interesting research and even more interesting path towards it.

I intend to request her for a motivational speech for the kids, attending a learn-by-doing-hands-on-experiments Adventure in Science non-profit group in Maryland.

Great spotlight and insight of the research by Callie and it is compelling to hear the backstory of how NIST's network of scientists, technology resources and partnerships within and outside the govt. labs are part of what Callie has leveraged to make such strides in her career. We are fortunate to have her growing leadership among the research ecosystem in Colorado!

- Dan Powers, Executive Director, CO-LABS