A decade in, NIST’s superefficient house continues to generate results and advance building science.

A House Ahead of Its Time

The house would hardly stand out if plopped into one of the neighborhoods that surround NIST’s sprawling Gaithersburg, Maryland, campus. Its sloped driveway leads to an attached garage. Pleasant eco-friendly landscaping, unassuming green-grey siding and classic-looking windows and doors all contribute to a sense of stately suburban normalcy. Only the unusually dense array of rooftop solar panels and the scientific equipment scattered around the perimeter hint that this house might be special.

Step inside, and any illusion of normality vanishes. This is, in fact, a very strange house — one humming with energy and activity despite having no flesh-and-blood occupants.

This house is not haunted, but it’s also not inhabited by humans. Its residents are electrical devices run by software. Sensors measure temperature, humidity, chemicals and more. Electric resistors resembling light bulbs mimic the heat released by human bodies. Software controls when water comes to a boil in the kitchen, when and for how long showers are taken, when lights flip on and off. What looks like a two-car garage houses racks of computer servers that log reams of data on every aspect of the house’s operations.

This is the NIST Net-Zero Energy Residential Test Facility, more commonly and affectionately known as the net-zero house. NIST researchers and collaborators designed the facility in the early 2010s with the goal of generating all the energy it would consume during a year — something accomplished by at most a handful of U.S. buildings at the time — and to serve as a laboratory for understanding how energy-saving technology impacts air quality, water quality and other essential features of a house.

The engineers, architects and scientists who designed the house wanted to not just load it with energy-saving appliances and features but also to test how the technology would perform in a residential house under everyday conditions. And they wanted to measure how complex systems such as HVAC, lighting and plumbing interact — something impossible to do in a conventional lab setting.

The level of integration and realism made the house unique in the United States and possibly the world, says Hunter Fanney, an emeritus NIST building scientist who spearheaded the project. “I longed for a facility where we could integrate everything into one laboratory,” says Fanney.

A Major and Growing Need

The NIST net-zero house was created to address a major — and growing — research need. Houses and other residential buildings account for more than a fifth of the energy used and greenhouse gases emitted in the U.S. Add commercial buildings, and that number jumps to more than 40%.

Heating, cooling, lighting and appliances all pull huge amounts of power from the electric grid, and most of that power is still generated by burning fossil fuels. It will be almost impossible to stabilize the global climate without making houses and other structures much more efficient.

Yet scientists lacked data on how highly efficient homes and buildings behave. It’s one thing to model such structures on a computer; it’s another to measure the performance of a real house inhabited by people, day in, day out, under unpredictable and ever-changing weather conditions.

While a few purportedly net-zero houses had been built, none provided a facility where scientists could test efficient building technologies in a realistic setting while controlling the behavior of the occupants. (Real people, after all, cannot be forced to take showers of specific durations or cook at certain times of day.)

The opportunity to create such a facility at NIST came thanks to the American Recovery and Reinvestment Act of 2009, which Congress passed in response to the 2007-2008 financial crisis and which pumped billions of dollars into U.S. science agencies. Energy efficiency was also a major government priority at the time. Fanney led a team that proposed that some of NIST’s outlay go toward a net-zero research facility; the project was selected and awarded $2.6 million.

“There had been some net-zero buildings built,” Fanney says, “but this was the first net-zero laboratory.”

Securing funding was only the first step. Designing the facility, led by a Massachusetts company called Building Science Corporation and the Department of Energy with NIST input, took a year and a half. Groundbreaking occurred in spring 2011; construction took another year and a quarter.

NIST scientists and their collaborators took numerous steps to make the house as efficient as possible. They used an advanced insulation package consisting of cellulose between the framing elements, a continuous membrane to seal out air and moisture, and a layer of foam panels on the exterior. The setup greatly reduced heat loss during the winter and heat gain during the summer.

The design team installed ventilation equipment to continually flush the house with outdoor air that’s pre-cooled or pre-warmed by stale air leaving the house, so the heating and cooling systems would have less work to do. The house earned the U.S. Green Building Council’s exacting LEED Platinum standard.

Equally important was designing a comfortable house that people would actually want to live in, says Bill Healy, a mechanical engineer at NIST who worked on the house. The team aimed to show that “you can live in an energy-efficient home, and it doesn’t have to feel like a science project.”

Finally, in September 2012, the 2,700-square-foot, two-story, four-bedroom, three-bath house was completed. “There was a huge amount of excitement,” Fanney says. “A lot of press releases were put out. The house had a huge following.”

Next, the project team outfitted the house with 400 sensors and tested it. The first big experiment started on July 1, 2013. The house had a year from that date to produce enough energy for the virtual family of four: two adults and two children. To accomplish that, the research team was counting on a 10-kilowatt, 32-panel solar array that blanketed the south-facing roof.

During the yearlong experiment, the house’s four “residents” cooked meals and cleaned dishes, took showers and washed hands, watched TV and played video games, charged their devices and in general lived like a typical, not particularly energy-conscious American family. They even gave off body heat and exhaled moist breath; electric heating elements and a humidifier were programmed to emit as much heat and water as a human body.

As one would expect for such a complex project, not everything went smoothly. The team soon realized that the house’s thermostat was forcing its heat pump to sometimes run in an inefficient mode, wasting energy. “It was a frustrating time,” says Healy. “We knew we could do better.”

A more severe challenge emerged when the winter of 2013-2014 turned out to be, by mid-Atlantic standards, unusually snowy and cold. At one point, a foot of snow smothered the solar panels for weeks, during which time the house needed to pull all its energy from the electric grid.

Despite the chilly temperatures, Fanney, Healy and their colleagues were sweating, worried their house would fall short of its net-zero promises. They even considered climbing onto the roof to push the snow off the panels, but realized that a typical homeowner likely wouldn’t take such a step, and that if they did so, it would compromise the realism of their experiment. The snow stayed.

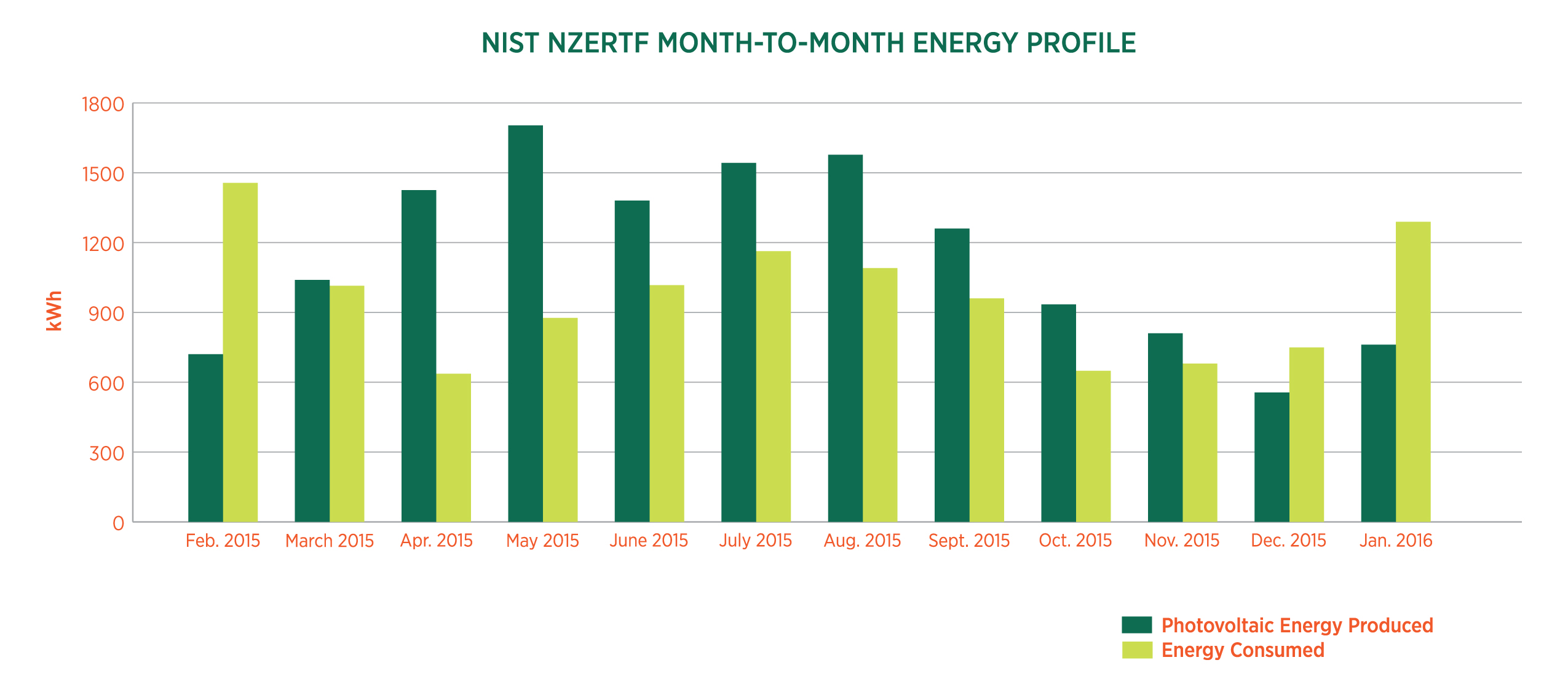

In the end, the house came through, producing 7% more energy than it needed. With excitement and relief, the team announced on July 1, 2014, that it had passed its big test. At the time, the annual electricity bill for a comparable all-electric home in Maryland was around $4,400, so the cost savings were substantial.

“We made it,” Fanney said at the time. “And by a convincing margin.”

The house achieved net-zero during its second yearlong run as well, proving the initial success was no fluke. Indeed, the house generated about four times the excess electricity in its second test year as it did in year one. (A milder winter requiring less heating with fewer days lost to snow-covered panels helped, as did a reprogramming of the misbehaving thermostat.)

As significant as it was, proving the net-zero concept was just the first act. The NIST house has gone on to become a test bed for a wide range of studies on energy, indoor air quality and more.

Indoor Air Quality Research: Many Questions, Few Answers

The NIST team set out to prove that net-zero was possible. But they also needed to answer a second, equally important question: Could they achieve exceptional energy efficiency without compromising inhabitants’ health?

This was no idle worry: To achieve net-zero, they had made their house almost completely airtight, cutting off natural ventilation that usually gives harmful chemicals inside houses a chance to escape and be diluted by outdoor air. “There’s a trade-off between energy efficiency and air quality,” says NIST environmental engineer Dustin Poppendieck, who has led much of the air-quality research involving the house.

Complicating the issue is the fact that scientists lack a full understanding of how potentially harmful airborne chemicals are produced by and move through buildings, in part because the Clean Air Act, originally passed in 1963, pertains only to outdoor air. When it comes to indoor air quality science, “we’re currently in 1970,” says Poppendieck. “We understand that there are problems; we need solutions."

Yet, in the U.S. at least, indoor air is arguably more relevant to human health, because we spend around 90% of our time indoors, according to the U.S. Environmental Protection Agency. And the chemicals of concern are many. Formaldehyde, emitted by adhesives in plywood as well as gas-burning appliances, can cause eye and throat irritation, nausea and breathing difficulties and is a known carcinogen.

Many other problematic compounds are also found in homes; some are even emitted by products used to enhance efficiency, such as insulating spray foam. People add chemicals to indoor air by using personal care products and cleaning agents. And gas stoves produce chemicals such as nitrogen dioxide, which can aggravate asthma and cause breathing issues.

Theoretically, the net-zero house’s mechanical ventilation system along with the selection of low-emitting products would protect air quality. But only measurements could confirm that. While energy researchers were monitoring the house’s energy production and consumption, air quality experts were keeping a close eye on the chemicals floating around its interior.

After 15 months of monitoring, NIST air quality researchers reported in August 2015 that even with its airtight construction, the net-zero house’s air was cleaner than that of new, conventionally built or manufactured houses. Formaldehyde levels were less than 80% of those expected in a standard home. Concentrations of other chemicals of concern showed similar trends.

The study also showed that the levels of chemicals rose in the summer as the building envelope heated up, which caused chemicals from building components to off-gas inside the walls of the house and enter the living space. In the winter, levels dropped again.

In follow-up studies, the air quality team turned off the house’s ventilation system for up to several days and found that concentrations of many chemicals quickly jumped.

While it’s hard to pinpoint when formaldehyde and other chemicals reach levels that could cause health problems, the NIST study underscored how important it is to actively ventilate tightly sealed houses — something rarely done in conventional houses in the United States.

“If there was no ventilation for a whole year, that would definitely be in the high-risk category,” says Lisa Ng, a NIST mechanical engineer who led a lot of the indoor air quality modeling.

“The net-zero house allows us to look at integrated systems that we wouldn’t have thought about otherwise,” Poppendieck adds.

Water Matters

After air heating and cooling, water heating is the largest energy user in a typical house. So naturally, NIST scientists paid attention to it, too. Tania Ullah, a NIST mechanical engineer, worked with the design team to fit the house’s plumbing system with sensors to measure energy use and water consumption. “We could take measurements that regular homeowners did not have the ability to do,” Ullah says. “They’re not able to put sensors within inaccessible areas of the home.”

The house designers eschewed the typical trunk-and-branch system — whose wide, rigid pipes can waste large amounts of energy and water — in favor of a more efficient “PEX” system that uses small, flexible plastic tubes to deliver hot water directly to sinks and showers. Still, they found that 12% of the energy used to heat water was lost as the water made its way to taps and faucets. Because the system was so well designed, this may represent close to the minimum amount of energy loss anyone could expect even in an efficient house, Healy says.

Another part of the hot water system was less successful — but equally instructive. In addition to the 32 power-generating solar panels, the house included four solar thermal panels for water heating, with a heat pump-driven water heater tank providing backup. But designing a cost-effective solar thermal system proved challenging in Maryland’s climate, because water in outdoor pipes can freeze in the winter. Instead, the panels heated coolant, which was then piped into the house to deliver its heat to water — a multistep design that inevitably creates energy losses. The system also required extra maintenance to function optimally.

After running the solar thermal system for two years, the NIST team abandoned it in favor of the more efficient and cost-effective heat pump-driven system.

Recently, Ullah and a NIST microbiologist colleague, Alshae’ Logan-Jackson, turned their attention to the house’s water quality. They zeroed in on the impact of one common strategy to reduce home energy use: lowering the temperature at which the hot water thermostat is set. While this strategy cuts the amount of energy the water heater consumes, there could again be a trade-off: If water that sits in a tank is not heated to a high enough temperature, harmful pathogens could breed in it.

To measure the concentrations of common pathogens that can breed in the net-zero house’s plumbing system, Logan-Jackson set the water heater to 120 degrees Fahrenheit (48.9 degrees Celsius), a temperature the Environmental Protection Agency recommends for conserving energy. Then she operated the house for several weeks under two conditions: heavier water use that would be expected for a family of four, and lower water use more typical of a solo resident. She then set the thermostat to a higher temperature of 160 degrees Fahrenheit (71.1 degrees Celsius) and ran the two scenarios again.

Logan-Jackson examined genetic material found in the water for traces of four pathogens — three bacteria and one protozoan. She got the most detections at the colder temperature and lower water usage level, with the Legionella pneumophila bacteria, which can cause the rare but serious Legionnaires’ disease, being the most common of the four pathogens in her samples.

The researchers also found they were most likely to get detections at the bottom of the hot water manifold — the central pipe that distributes water to the tubes — a location where both water temperatures and disinfectant levels can encourage pathogen growth. Redesigning the manifold to eliminate this “dead end” or regularly draining the system could help reduce pathogen levels, Ullah says.

The study results, which the researchers are preparing to publish, confirmed the hypotheses that heating the water to a higher temperature and using water at a higher rate both reduced pathogens living in the plumbing system, say Ullah and Logan-Jackson.

What that means for health will require further study. Most people will not get sick from minor exposures to Legionella bacteria, and their presence alone does not indicate that keeping hot water at a lower set point is dangerous. But, Logan-Jackson says, the study indicates the need for more research. “There is something happening here, and the data show us that.”

A Full-House Research Project

In 2022, two dozen scientists from 12 universities descended on the NIST net-zero house. They packed the garage and the house with sensors, computers and measurement equipment.

Their research project, years in the making, comprised what might be the most ambitious use of the net-zero house in recent years: the Chemical Assessment of Surfaces and Air (CASA) project. The project aimed to use the NIST house to measure how pollutants such as wildfire smoke and everyday activities such as cooking and cleaning affect indoor air chemistry — and under which circumstances they could harm occupants’ health.

The project’s leaders, chemists Delphine Farmer at Colorado State University and Marina Vance at the University of Colorado Boulder, had done earlier experiments using houses on university campuses. But the ability to precisely control and measure a wide range of variables made the NIST net-zero house “the perfect test bed for these sorts of experiments,” Farmer says.

The scientists injected ammonia and volatile organic compounds into the house and tracked how these chemicals were transformed through reactions with walls and other surfaces. The researchers operated commercial air cleaners to assess their efficacy. They tweaked temperature, ventilation rates and humidity. They measured the chemicals produced when they cleaned with various cleaners and after cooking a variety of meals. (The experiments were originally scheduled for 2021 but were pushed back due to the COVID pandemic.)

The researchers had some more whimsical ideas as well. “People wanted to see what the emissions from popcorn were,” Farmer recalls. “We definitely had some fun with cooking in the house.”

One of the team’s biggest questions was: What happens when wildfire smoke gets into a house? It’s an increasingly urgent question as climate change gives rise to larger and more frequent fires. And while wildfire may once have seemed remote from NIST’s Maryland campus, much of the eastern U.S. was blanketed with smoke from Canadian forest fires during the summer of 2023, making clear that wildfire smoke is a widespread health hazard.

Typically, when outdoor air is full of smoke, people are advised to stay inside, but smoke can also penetrate houses and pollute indoor air. To simulate wildfires without actually starting one, the scientists burned wood chips inside cocktail smokers and then pumped the smoke into the house, creating a mix similar to the potpourri of organic compounds and particles that a real fire produces. Thirteen sensors tracked those particles throughout the house.

The availability of a realistic house without human occupants was crucial, Farmer says. “There isn’t any reasonable person out there who would be willing to have wildfire smoke added to their house just for the sake of science.”

Measurements showed that chemicals in the smoke adhered to and penetrated the walls and other surfaces of the house more than expected, even when the researchers ran commercial air purifiers. As a result, occupants could be exposed to smoke chemicals long after they stop wafting in from outside.

The scientists also found that vacuuming, dusting or mopping surfaces substantially reduced the occupants’ exposure to harmful compounds. Opening windows, by contrast, lowered the concentrations of chemicals initially, but that benefit quickly disappeared when the windows were closed again.

Indoor environments have far more surfaces than outdoor ones, and compounds sticking to those surfaces create an “almost infinite source of chemicals” that can contaminate indoor air, explains Poppendieck. So paying attention to surfaces is key to removing indoor contaminants. He says the top-line result of the smoke study “wasn’t a surprise, but it was a good confirmation.”

The team published its first findings last October in the journal Science Advances, and a description of the overall project in Environmental Science: Processes & Impacts.

The CASA team also found that even seemingly minor uses of commercial products or everyday activities can substantially change the chemicals floating around inside a house. More papers detailing these findings will be coming out in the coming months.

“The CASA project really highlights the importance of being able to have academic researchers work with federal agencies to push the bounds of research,” Farmer says. “We can use the enthusiasm and capacity of universities and the facilities and expertise at NIST.”

Real-world impact

The CASA study provided valuable lessons for those returning to their homes after the January 2025 wildfires in Southern California. Based on her team’s findings, Farmer recommends opening windows and doing a deep clean to extricate smoke particles embedded in floors, furniture, fabric and HVAC systems. Read more.

Modeling a Greener Future

One of the net-zero house’s most important outcomes has been validating and improving computer models such as the Department of Energy’s open-source EnergyPlus, says NIST mechanical engineer Brian Dougherty, who has coordinated research at the house since Fanney retired. This model is widely used to estimate building energy use, but it and similar models were built mostly using data from conventional buildings rather than efficient houses.

NIST scientists also used measurements from the net-zero house to verify models produced by CONTAM, a NIST software program that is among the best in the world at simulating air flow and exposure to pollutants inside buildings. Researchers coupled EnergyPlus and CONTAM together to model how temperature, energy and air pollution interact, going beyond what either model could achieve on its own.

Because they had years’ worth of measurements from the net-zero house, the scientists were able to validate that the coupled model accurately predicted how concentrations of chemicals such as formaldehyde and flame retardants rise and fall with changing temperatures and weather conditions, boosting confidence that the model captures key features of efficient houses.

“We’re pretty confident that it’s a good model, but to verify that it could perform well in a real building, that was a nice thing about this study,” says Stuart Dols, a NIST mechanical engineer who leads CONTAM development. “It was a really good chance for us to work with a building that has very low infiltration.”

Poppendieck adds that a paper from the CASA project using results from the smoke study to further validate and refine CONTAM is in the works.

One area where the house has not had a major impact — at least, not yet — is in spurring a wave of net-zero home construction. The primary barrier, says Dougherty, is cost. The solar panels, insulation, ventilation equipment and other technology required to achieve net-zero added $162,700 to what it would have cost to simply meet Maryland’s building code requirements at the time, per an estimate by NIST economist Joshua Kneifel. Recouping that investment would have taken decades’ worth of energy savings — longer than most homeowners can wait.

Indeed, a 2015 modeling study by Kneifel and others found that the houses that delivered the best value for buyers were built to exceed Maryland’s home energy efficiency requirements, but stopped short of net-zero.

Today, we’re seeing another wave of enthusiasm for home energy efficiency. And thanks to the falling prices of green-energy technology and new government building codes and financial incentives, net-zero construction may be more economically achievable than ever. Even builders who don’t aim for full net-zero can benefit from better science on how energy-saving technologies and practices affect energy use and indoor air and water quality.

For example, Kneifel says, solar panels have gotten so cheap that it may now be more cost-effective to add extra panels to a house and generate more electricity, rather than add large amounts of insulation to drastically reduce energy use as the NIST team did.

“In Maryland, if you’re going to be in a home for 15 years, I think the math works out to get close to net-zero, if not all the way there,” says Kneifel. “I think in most cases you can get close to net-zero cost-effectively.”

Another important lesson from the net-zero house has emerged over time, says Healy. Builders sometimes question the durability of efficient houses — some worry, for example, that sealing a house too tight can allow mold to grow. The net-zero house has shown that good design can prevent such problems and create a structure that stands the test of time, says Healy.

“There are a lot of systems that have really worked well. The house was built well; 12 years in, it’s holding up well,” Healy says. “If you pay attention to the details of energy efficiency, it has other benefits.”

The next big project on the agenda for the house, says Dougherty, is an experiment to measure the performance of ground-source heat pumps — a costly but highly efficient technology that runs fluid through pipes underground, tapping the Earth’s near-constant temperatures to heat and cool the house. It’s an experiment that’s been lying in wait for over a decade: The heat pumps and three different sets of underground pipes were installed during construction, but due to competition among researchers who want to use the house, they have never been turned on.

When they finally are, it will be yet another demonstration that a decade in, NIST’s one-of-a-kind house continues to churn out data that can help us all live a little bit greener.