Masks Under the Microscope

Viewed under a microscope, mask fabrics are complex, varied and beautiful.

To understand how something works, it helps to see it up close.

A team of researchers took this approach when studying the fabric masks that people wear to slow the spread of COVID-19. Those masks work by blocking some of the virus-filled droplets and smaller particles, called aerosols, that an infected person exhales, and they also offer some protection to the wearer by filtering incoming air. The researchers wanted to know how well different fabrics filter out those particles and what makes some fabrics better filters than others.

Their research indicates that that cotton fabrics tend to perform better than synthetics, with cotton flannels being particularly effective. After being exposed to the moisture in a person’s breath, cotton fabrics perform better still.

As part of this research, one team member, Edward Vicenzi, used a scanning electron microscope to examine the fabrics up close. Vicenzi works at the Smithsonian’s Museum Conservation Institute, where he studies the history and origin of objects in the museums’ collection. He is also a visiting researcher at NIST. His images gave the scientists important insights into the particle-filtering properties of different fabrics. And they can give us all a sense of the beautiful, textured, woven world right in front of our faces.

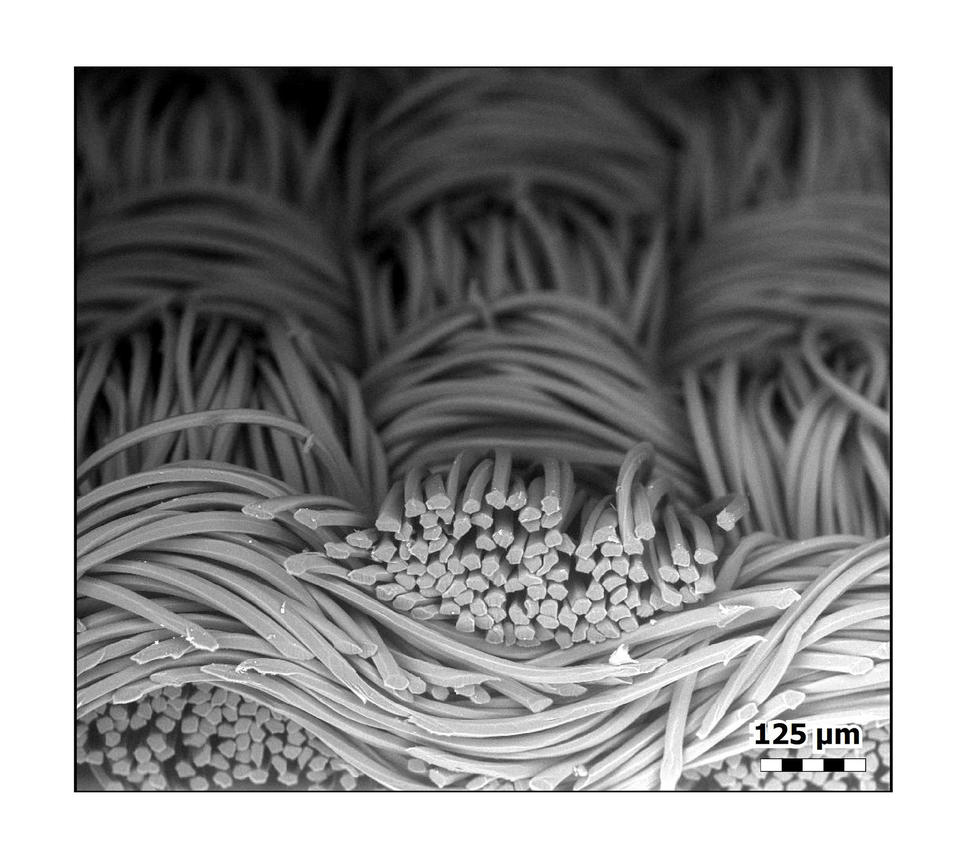

Polyester is a synthetic material that, like many fabrics, is made up of individual fibers bundled into yarns then woven together. This image shows the cross-sectional shapes of the individual fibers. The researchers used images such as this one to measure the width of the individual fibers — a key variable that affects particle filtration.

The entire scale bar in this image is 125 micrometers, or millionths of a meter, wide — a bit wider than an average human hair.

Aerosols that might contain the coronavirus vary in size, but smaller ones might be one-hundredth the width of the fibers in this image, and some are even smaller. Fabric masks do not capture all of these small aerosols, but they capture many of them, which slows the spread of the disease.

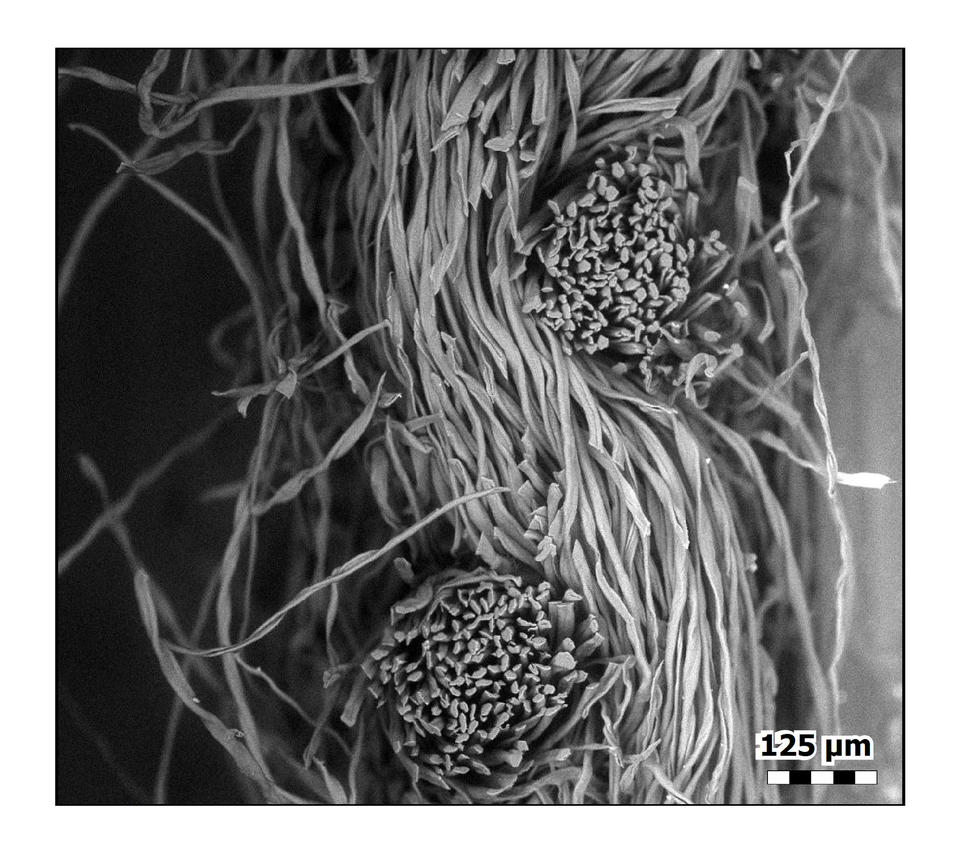

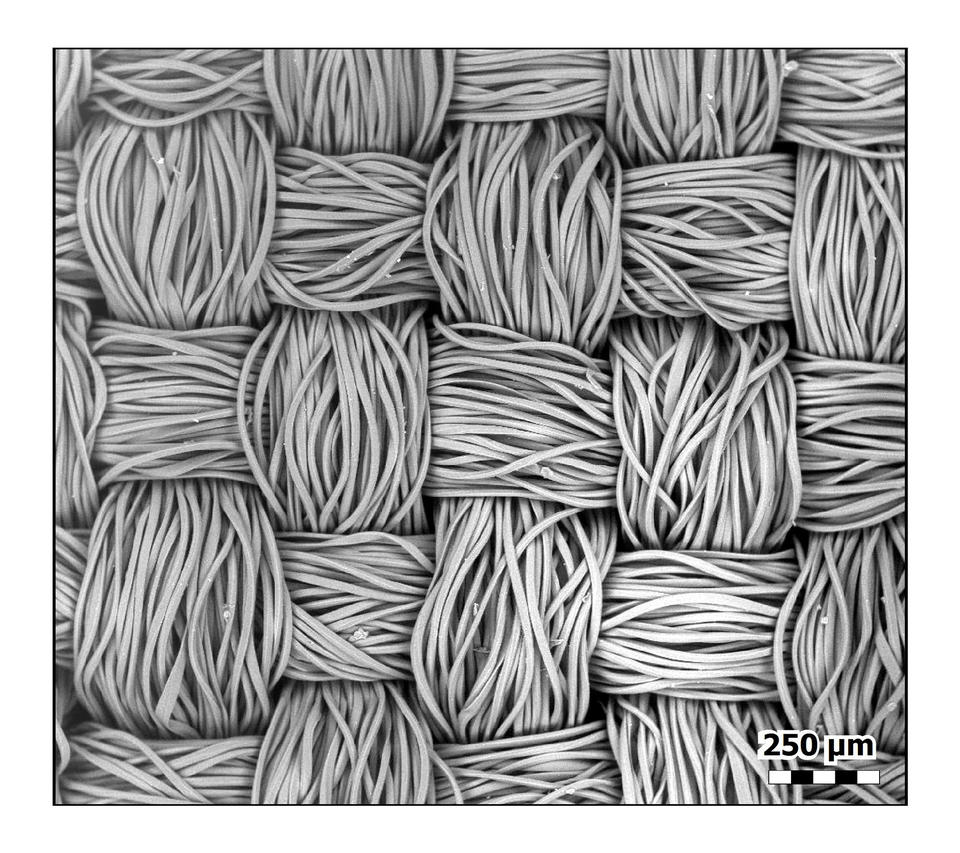

This image shows the cross section of a cotton flannel and its over/under weave. In addition to measuring the width of individual fibers, the researchers used images like this one to measure the thickness of the fabrics — another important variable that affects their ability to filter particles.

In addition to measuring these microscopic variables, the researchers also measured the filtration performance of the fabrics. This allowed them to understand how these variables affect filtration and how masks work on a microscopic level.

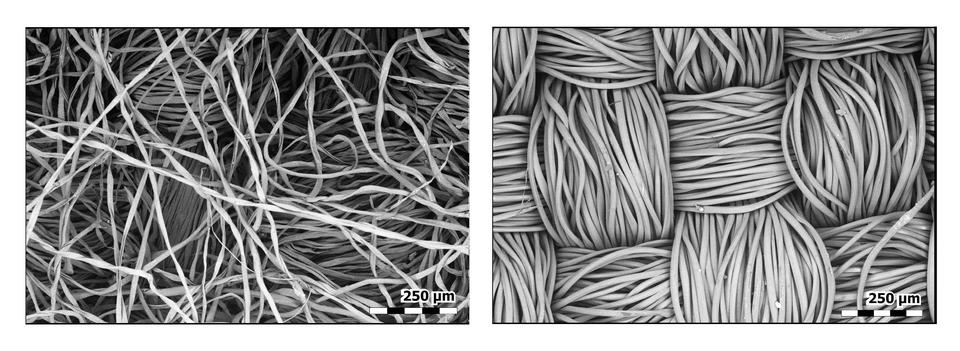

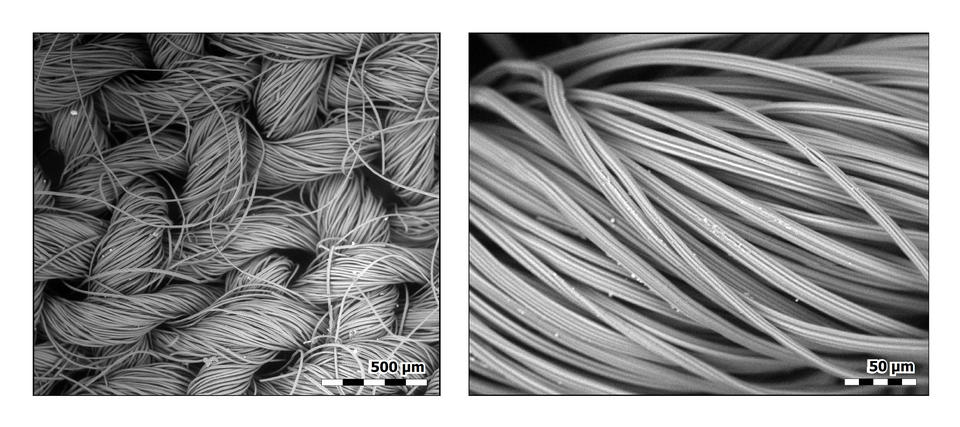

This image shows top-down views of cotton flannel (left) and polyester (right). The weave of the cotton flannel is hidden below a disorganized network of crisscrossing fibers. These raised fibers make flannel feel soft to the touch. In contrast, the fibers in this polyester are very organized and consistent.

The NIST researchers think that cotton flannels are particularly good filters in part because of the chaotic arrangement of their fibers. This increases the chance that an aerosol passing through the fabric will collide with a fiber and stick to it.

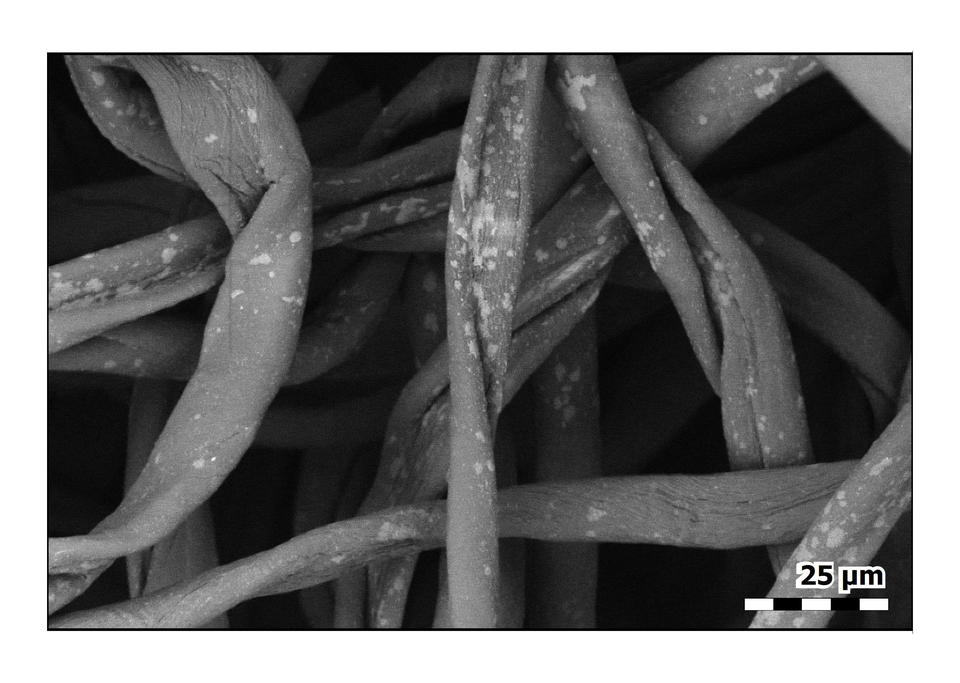

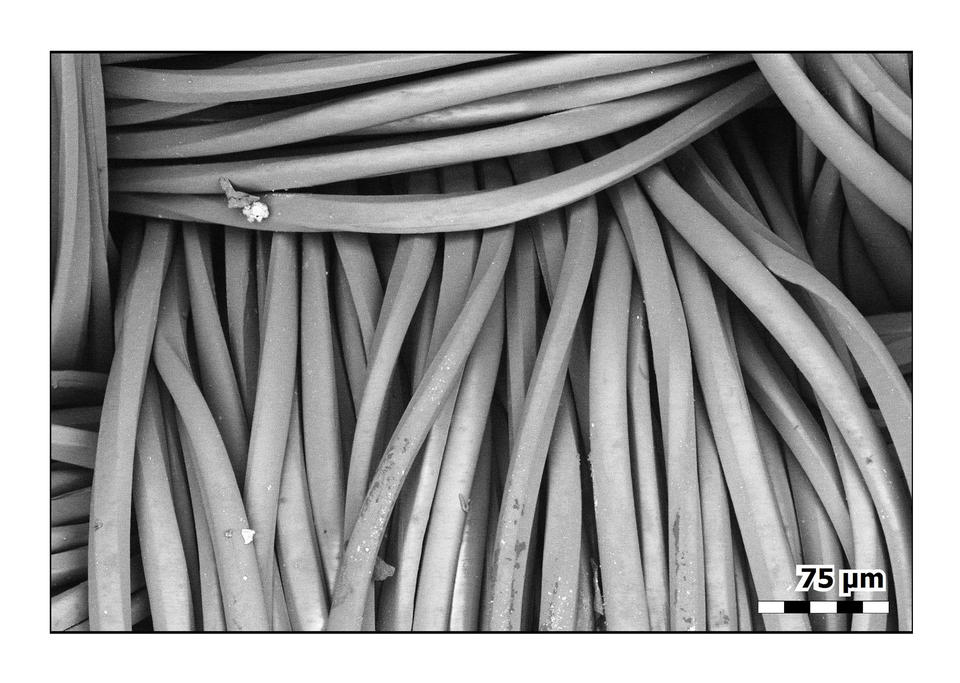

This image shows the individual fibers in cotton flannel. When you breathe through a mask, the air flows around these fibers and the aerosols are pulled along for the ride. The aerosols can be very small, but they do have some mass. As the air bends and twists around the fibers, some of the aerosols can’t turn fast enough and smash into and stick to them. NIST researcher Chris Zangmeister likens this to the scene in Star Wars: The Empire Strikes Back when starfighters are streaking through the asteroid field. Only the smaller ships could turn fast enough. The Star Destroyer couldn’t make it through.

Seen up close, cotton fibers have kinks and bends. This increases the amount of surface area that an aerosol can stick to. In addition, cotton fibers are hydrophilic, meaning they like water. By absorbing small amounts of the water in a person’s breath, cotton fibers create a moist environment inside the fabric. As microscopic particles pass through, they absorb some of this moisture and grow larger, which makes them more likely to get trapped.

This top-down view of polyester shows how the fibers stay nicely bundled. This image is from the same type of fabric as those quick-drying shirts you might wear to the gym. Those shirts dry quickly because the fibers are hydrophobic, meaning they don’t like water. Unlike cotton, polyester fabrics do not become better filters when exposed to the moisture in exhaled breath.

Polyester fibers are manufactured using a process called extrusion, in which the polymer raw material squeezes through an opening, like spaghetti coming out of a pasta maker. This causes the fibers to have a consistent cross-sectional profile and, in this case, a smooth exterior with less surface area than cotton fibers.

Some fabrics are harder to categorize. Rayon is considered synthetic, but it is derived from plants. To create it, manufacturers treat plant material such as bamboo with chemicals. That releases a plant fiber called cellulose, which is then restructured into a soft material and extruded into rayon fibers. The result is a hybrid material. The fibers are hydrophilic, like many natural materials, but have a consistent cross-sectional shape, like many synthetics. Still, cotton fabrics are much better filters than rayon.

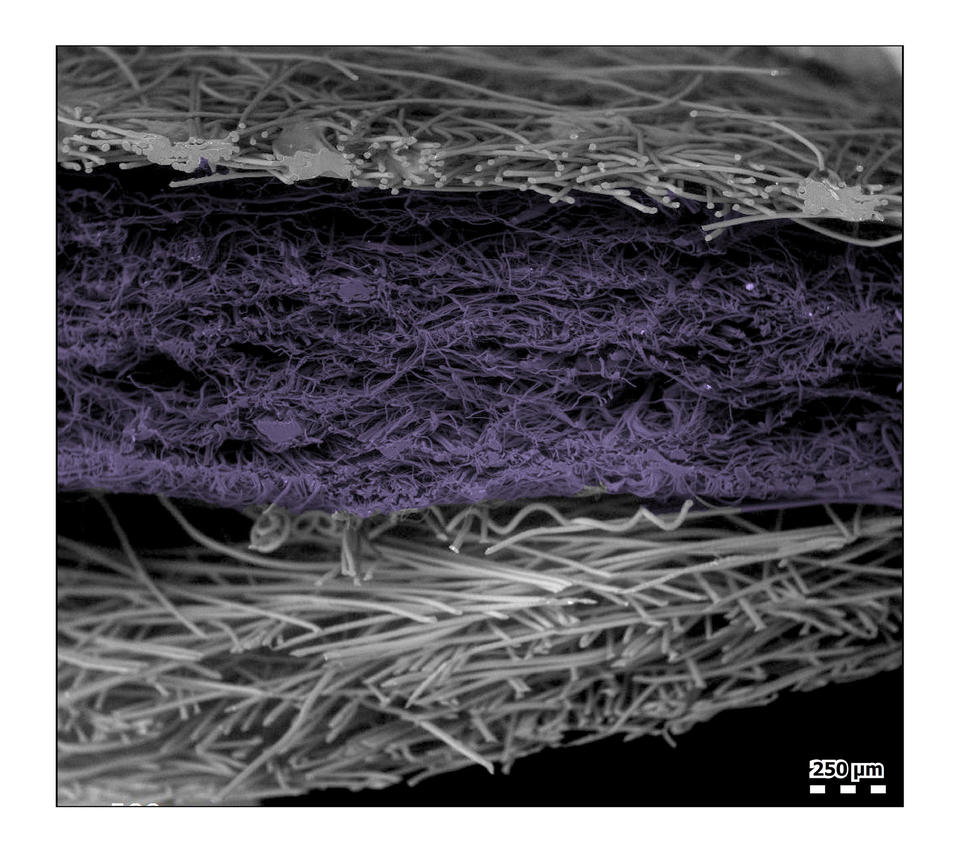

While cotton is best for the fabric masks that the general public uses, medical-grade masks are a different story. This false-color image shows a cross section of one layer of an N95 respirator mask, including filtering material, shown in purple, and protective material around it. This layered structure then repeats for added protection. The filtering material is made by melting and then air-blowing polypropylene, a type of plastic, into a chaotic web. The fibers are far smaller and have much greater surface area than cotton fibers, which is one reason this is an especially effective filtering material.

N95 respirators get their name because they filter out 95% of particles that are 0.3 millionths of a meter in size. Their filtration performance is well known because there have long been standards for medical grade masks. The first standards for fabric masks were recently released. The NIST studies described on this page and studies by other organizations contributed to the development of those standards, which will give people in nonmedical fields information on how well their masks work.

NIST scientists are still working to gain a better understanding of the filtration properties of mask fabrics. As people continue to wear fabric masks to limit the spread of COVID-19, or if the need should arise again in the future, these tiny details will help.

In addition to microscopy, NIST scientists are also using high-speed video and other techniques to show how air flows through and around masks.