Want to Avoid Problems in Powerful New Drugs? Ask a Roofer.

Popular new construction material helps measure protein particles

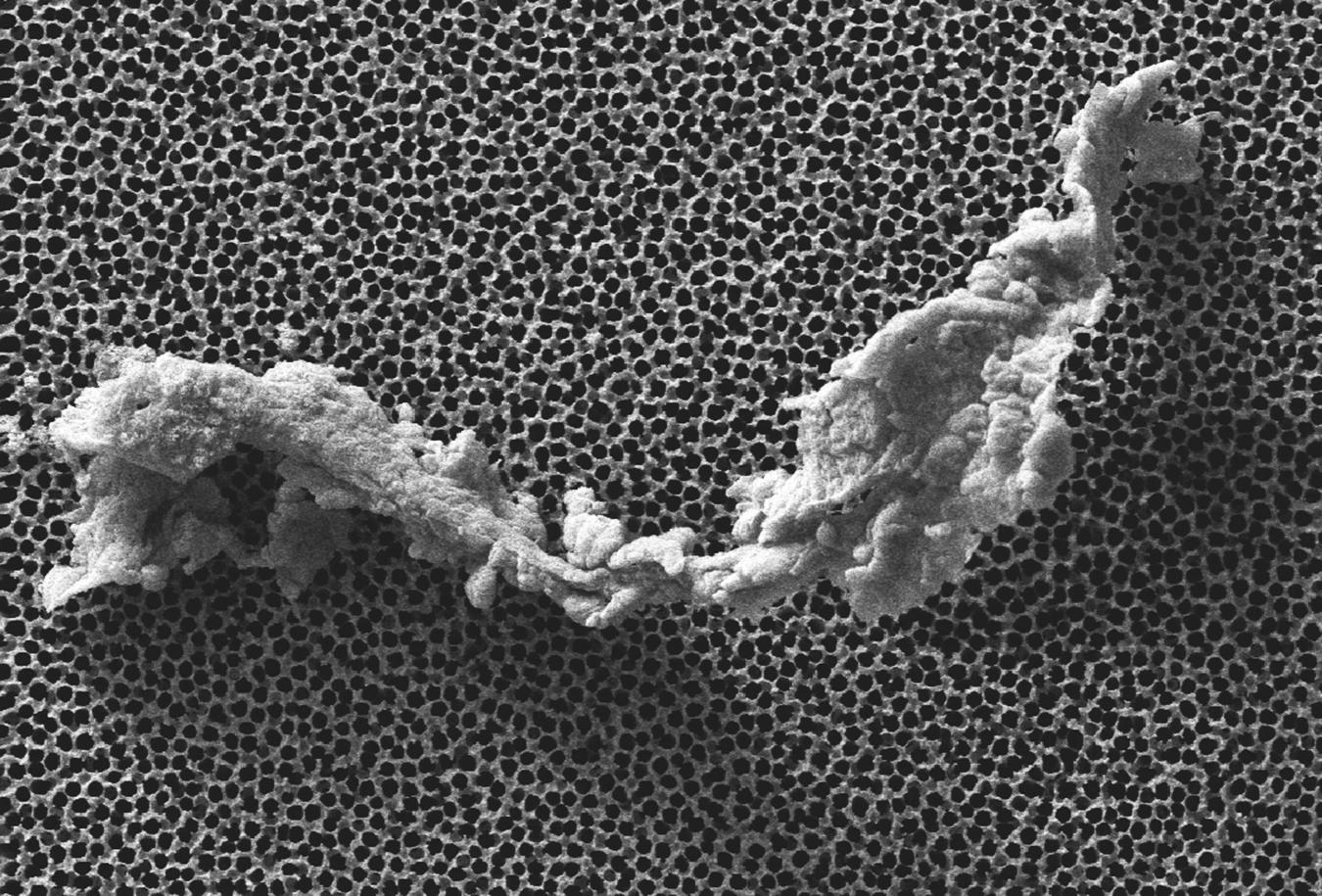

Protein particles are not spherical, although some of the tools used to measure them are spherical.

Understanding how proteins clump together is essential in modern pharmaceuticals. When these tiny particles aggregate, they can alter the effectiveness of both vaccines and drugs, especially many of the new, popular formulations derived from monoclonal antibodies. Despite its importance, the industry has yet to find an effective, large-scale way to measure particle clumping accurately. A new reference material, released today by the National Institute of Standards and Technology (NIST), aims to solve this protein problem with help from a translucent wonder material that’s often used on stadium roofs.

Biologic drugs are being prescribed today for a wide variety of ailments and diseases, including cancer, psoriasis, colitis and rheumatoid arthritis. Unlike the conventional medicines, biologics are full of living proteins. Those proteins can clump together during manufacture, shipping, or storage. Scientists would like a way to know when that happens because such protein particles can cause unwanted immune responses, so for years, they sought to create a “reference material” that could help with quality assurance and instrument calibration.

A body’s immune system is designed to recognize viruses and bacteria that are anywhere from 10 nanometers to 10 micrometers in size. Clumps of proteins that can form in biologic drugs are often this same size, which can be problematic.

“If you put something in the body that is within that same size range, it potentially raises a red flag for the body,” explained NIST scientist Dean Ripple. “Sometimes that’s desirable. In the case of many vaccines, you intentionally make particles or add clumped particles so that the body will say, ‘Oh, I really need to pay attention to what I’ve just been injected with.’ It causes a positive immune response.”

But when working with a drug product, Ripple added, “you want to quietly sneak that into the body and not raise the immune system’s alarms. You don’t want the drug product to look like an invader.”

In both vaccines and biological drugs, being able to quickly and precisely measure the aggregations would be useful. The most popular method uses light to identify particles by measuring how they scatter or absorb a beam of light passing through the sample. A detector measures changes in beam intensity as particles in a flowing sample stream through the beam. A bigger reduction in light intensity means a bigger particle is in the sample. Another method uses a microscope that captures images of a flowing sample and automatically identifies particles in the images.

Polystyrene spheres, made of the same material used in beach coolers and packing peanuts, are typically used to calibrate instruments, essentially helping to teach the automated machine what particles look like. The polystyrene spheres come in various sizes and are widely available. But they are extremely regular in shape, unlike protein particles, which tend to be irregular and wispy. Polystyrene also refracts, or bends, light quite strongly, while protein particles cause much weaker refraction.

A NIST team, led by Ripple, began working on solving this clumping measurement problem after the Food and Drug Administration identified it as an issue in the development of new biological drugs.

The team considered many substitutes for the spheres and beads before finding inspiration from a surprising source: the building industry, where a product called Ethylene Tetrafluoroethylene (EFTE) has become a favorite of architects who like its resilience and the way it can be beautifully backlit for aesthetic purposes. Several new sports stadiums, including the one used by the Minnesota Vikings, are clad in EFTE and are lit up with the team’s colors on game days. Ripple wondered if he could damage it in a very controlled manner that would make small particles of EFTE into a new, helpful size and shape.

“After examining the stuff, I found myself saying, let’s try to make something with this ourselves. I brought in some sandpaper usually used for hobby projects and put on some nitrile gloves and began rubbing a sample of EFTE with the paper until we had enough to play with under a microscope,” he says.

What the team found was that the sturdy, light-refractive particles became wispy and tangled in shape, very much like protein particles.

Since the initial tinkering, NIST has scaled up and formalized the production process and developed a reference material that anyone can purchase for both research and manufacturing applications. In addition, a private company is beginning large-scale manufacturing of abraded EFTE particles for use by the biopharmaceutical industry.

Learn more about this NIST standard reference material.