A process for identifying suitable replacement materials that relies only on ballistic performance validation tests would be expensive and require extensive testing, and it still would not identify material properties that are useful for formulation-development and quality-control purposes. To overcome this, a team of NIST researchers, working in collaboration with the Army Research Laboratory (ARL), developed a rheological framework to facilitate standardization of the formulations, in-situ process monitoring, and quality control evaluation of the candidate ballistic witness materials (BWMs).

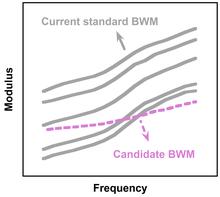

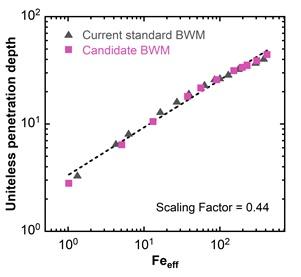

The Army candidate BWMs exhibit minimal temperature sensitivity and smaller variations in material properties compared to the current clay, both of which are desired for improved repeatability in backing material verification testing conducted prior to ballistic testing and during body armor ballistic resistance testing. For end-use purposes, identification of key material properties is critical to ensure that a BWM will satisfy performance requirements. Important criteria for a BWM are that it is dimensionally stable, deforms easily upon impact, and exhibits minimal elastic recovery after deformation. By performing large amplitude oscillatory shear (LAOS) measurements, the candidate BWM is identified as an elasto-visco-plastic material, similar to the current clay. This means that for applied stress below the yield stress, the material behaves as a viscoelastic solid; upon elevated stress exceeding the yield stress, the material deforms irreversibly and flows as a fluid, but with permanent deformation. This characteristic is particularly important for accurate determination of the behind-armor backface signature of a BWM, a common metric used in the performance evaluation of body armor.

Valuable material data on candidate BWMs recently developed by the U.S. Army are reported in [1]. Along with ARL’s report, the results from [1] support the synthetic polymer composite as a promising replacement BWM for the current clay for body armor performance testing. This work highlights the effectiveness of our methodologies to help optimize formulations, to set quality control guidelines, as well as to establish documentary performance standards and specifications related to next-generation BWMs for body armor testing.

________________________________________

[1] R. Tao, K.D. Rice, A.S. Djakeu, R.A. Mrozek, S.T. Cole, R.M. Freeney and A.M. Forster. Rheological Characterization of Next-Generation Ballistic Witness Materials for Body Armor Testing. Polymers 2019, 11, 447. DOI: 10.3390/polym11030447

Related NIST Instrument/Tool

RELATED NIST PROJECTS

Rheological Characterization of Ballistic Witness Materials

Materials and Systems for Protection Against Penetrating and Blunt Force Phenomena

Body Armor and Related Materials