Some of the most dangerous fires are the ones you don’t see coming. That goes not only for fires in buildings but for those kilometers off the ground, aboard commercial airliners. Many aircraft have systems to detect fires early on, but fires that spark in their attics, or overhead compartments — spaces with curved ceilings, filled with air ducts, electrical wiring and structural elements — could potentially sneak past them.

“Attic fires are less likely to occur than elsewhere in a plane, but they are hard to detect,” said Haiqing Guo, a contract fire research scientist at the Federal Aviation Administration (FAA). “By the time you see it, it’s too late.”

Fire detector placement in overhead compartments is particularly challenging for fire protection engineers as it is unclear how to predict where smoke will travel amid the irregularly shaped clutter. A fire-simulating computer model developed at the National Institute of Standards and Technology (NIST) could now offer some much-needed guidance thanks to recent updates. In a new study, a team of NIST and FAA researchers tested the tool against a real-world scenario, where fires burned inside a grounded airliner, and found that the software closely replicated measured temperatures and correctly identified hot spots in the attic.

NIST’s Fire Dynamics Simulator, or FDS, simulates the flow of heat and smoke produced by fires. Since its launch in 2000, the software has been used by engineers across the globe to design fire protection systems for buildings and for forensic reconstructions of real-life fires. In both cases, engineers use the software to learn how a fire would or did burn without having to perform full-scale tests first, which are costly and sometimes impractical to run.

FDS can reliably model the behavior of a fire in the presence of flat surfaces and block-like objects. This capability is good enough for the lion’s share of scenarios, as most rooms are rectangular in shape. But curved surfaces, such as uneven terrain outdoors or the ceilings of trains and planes, have sometimes thrown the software for a loop.

To manage this limitation, engineers using past iterations of FDS would approximate curved surfaces with small boxes, but a new version can do better. A recent update allows FDS to understand smoother surfaces made of triangles, bringing its simulations closer to reality in certain cases.

While researching aircraft fire safety at FAA, Guo became intimately familiar with the puzzle of detecting attic fires. Upon learning of FDS and its new capabilities, he believed he had found a tool that could help crack the case, and he reached out to NIST’s fire researchers.

NIST and FAA formed a team to test the software by comparing its simulated data to real data collected in the overhead space of a commercial airliner parked at the FAA William J. Hughes Technical Center. The team placed a gas burner in either the front or rear of the space and — with five firefighters on standby — lit a small flame, which represented an attic fire in its earliest stages. They also arranged 50 temperature sensors throughout the space to capture how the hot smoke traversed the attic’s complex terrain.

The study’s authors produced a map of the overhead compartment via Light Detection and Ranging, or lidar, a technique that employs laser light to measure distances in three dimensions. With the lidar information as a blueprint and hundreds of thousands of triangles as digital building blocks, they constructed a digital version of the space as a setting for the FDS simulations.

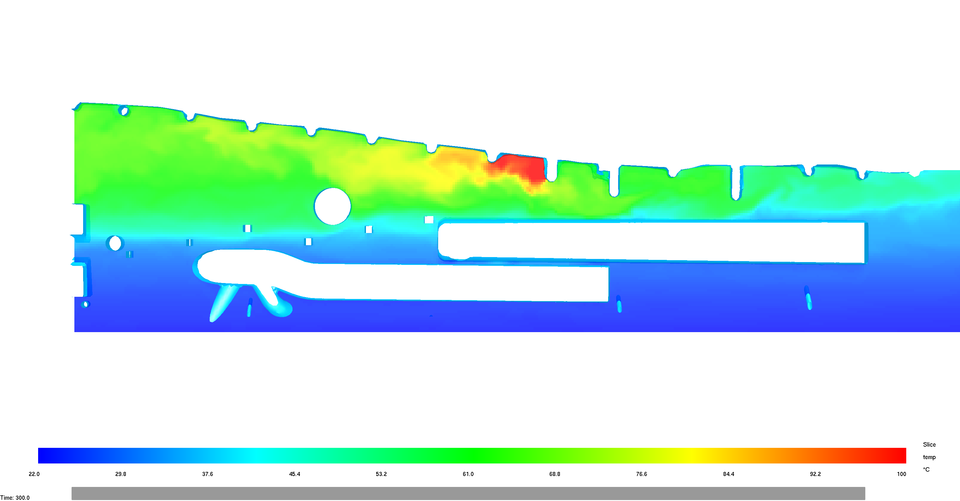

The team ran and compared both the experiments and simulations, finding a general agreement between the two. A layer of hot gas took shape near the ceiling in both scenarios, with the same pockets of hot air having formed between the metal ribs that lined the ceiling above the gas burner.

The initial jumps in temperature occurred at almost the same time between data sets. The temperature values themselves were similar too, with the simulated heat near the ceiling landing within 5 C (9 F) of the measured values on average.

“This level of disagreement between model and experiment is typical for full-scale tests, so the model results are reasonable,” said NIST chemical engineer Randall McDermott, a co-author of the report. “Ultimately, our goal is to be within experimental uncertainty. So, a bit more work is needed to track down the sources of error in this particular case.”

These results show that the new FDS can capture several traits of a real overhead compartment fire and suggest it could, with further development, become a reliable tool for fire protection engineers designing aircraft systems in the future.

The team seeks to take FDS down that path, testing it against fires in differently shaped attics and examining whether the tool can replicate other aspects of fire in these spaces, such as smoke concentration, another important metric for fire detection.

Further down the road, the researchers say FDS could be useful for learning not only how to detect fires, but how to put them out as well. By modeling fire suppression systems, such as fire sprinklers, engineers could gather valuable details about how to extinguish or slow the spread of fires.

FDS may also demonstrate how prospective fire suppression agents would flow and mix with smoke in irregularly shaped spaces. Performing these virtual tests would help researchers to identify new chemicals or systems well suited for the job and provide insights on how to best implement them.