Manufacturing Innovation Blog

Powered by the Manufacturing Extension Partnership

This blog is part of a monthly series brought to you by the America Works initiative. As a part of the MEP National Network’s goal of supporting the growth of small and medium-sized manufacturing companies, this series focuses on innovative approaches and uncovering the latest trends in manufacturing workforce development.

German manufacturing is a powerhouse, fueling 21% of the country’s economy and contributing nearly $1.4 trillion in exports. Given these facts, we in the MEP National NetworkTM have been studying Germany’s vocational educational training (VET) program, which most of us call apprenticeships, by going overseas and talking directly to German stakeholders. Back in December 2022, I shared five lessons we learned from Germany in our October 2022 trip. I like to call that webinar and blog post German Manufacturing 101.

Today, we’re taking that one step further with our German Manufacturing 202 class. In February 2023, America Works and the American Council on Germany coordinated the second of three trips, and now we’re ready to move beyond the basics of the German VET system. Upon returning, the 17 Stronger Together mission participants hosted a webinar we called “What We’re Bringing Back from Germany” full of lessons for American policymakers, companies and other stakeholders.

As a reminder, the goals of these international learning trips are to:

- Understand Germany’s approach to VET, aka apprenticeships.

- Facilitate detailed conversations and best-practice sharing between workforce development professionals in both countries.

- Inspire change and improvement of America’s VET system directly through projects, media publications, and education for the entire MEP National Network.

What MEP Centers can do

In our discussions, all the mission participants agreed that the American manufacturing industry has all the individual pieces, but these entities need to be woven together. Schools, companies, colleges, government institutions, and nonprofits are all key stakeholders, but rarely work together in a significant way. That’s where MEP Centers come in.

First, MEP Centers can start by mapping their local apprenticeship ecosystems. Who are the players? Do any local companies have European affiliates where the apprenticeship is already running and could be brought to the U.S.? Where are the gaps? Where can the MEP Center add value? Can manufacturers active in apprenticeships help by mentoring those that are considering it? Answering these simple questions can lead to a clear playbook for how an MEP Center can support and advance its local workforce ecosystem. Through the concept of sector partnership, an MEP Center can place itself in the center of a local ecosystem, and conduct the disparate instruments into one clear song.

What youth and education-focused institutions can do

What is exciting about German educational institutions is the way they use hands-on projects to link theory with practical skills necessary for success on the plant floor. School projects develop thinking skills and practical knowledge, and students are expected to share their work with others. When students get excited about the work they are doing, they become immune to any negative stigmas they hear from others. It’s not that there is no stigma against manufacturing in Germany, it’s that students are fully engaged and don’t listen to outside criticism. We heard several German apprentices say that while other people might not understand manufacturing, they love it and look forward to coming to work every day.

In Germany, apprentices are paid monthly when they attend and perform at both school and work. In addition, the standardized apprenticeship certification German students receive is recognized nationally. We recommend that American training programs seriously consider nationally recognized certifications like the National Institute for Metalworking Skills, Amazon Web Services, and the Manufacturing Skill Standards Council. MEP Centers can work with these national bodies to better align the needs of small, local manufacturers with the national curriculum’s evolution.

Finally, until we reach the day when manufacturing careers are viewed as equally prestigious as law, medicine, or other white-collar careers, the nation’s educational organizations need to actively promote manufacturing. Short-term internships with manufacturers should be actively publicized so students can learn firsthand on the plant floor. Career awareness programs such as the What’s So Cool About Manufacturing? student video competition, field trips to see factories in action, virtual reality tours of manufacturers, and in-school robotics teams are all critical to exposing young people to the potential of manufacturing careers.

What companies can do

When it comes to learning from Germany’s best practices, half the battle for American companies is cultural. We value speed and productivity and don’t realize that learning takes time. We have to stop viewing apprenticeships as a burden and start seeing them as an opportunity to strategically, thoughtfully develop future talent. We must align our company values with learning and development for the long term, not just a specific role. In Germany, young employees feel valued and respected because even small manufacturers have dedicated staff, space, and budget specifically for training apprentices. As one MEP participant tells his manufacturing clients, “Stop saying you value training, but never dedicate staff time to actually engage in it.” Make sure you’re leading with your tuition reimbursement program so potential employees know they can advance their own educations. Remember that, as with any investment, the return doesn’t come immediately, but takes time. Embracing Germany’s long-term, employee-centric approach will result in higher retention and attraction of new workers.

Companies should also use their partnerships to drive worker recruitment through internships, career fairs, Manufacturing Day and other creative approaches. German companies simply offer more flexible on-ramps to manufacturing careers, starting in ninth grade and continuing through graduate school. The common complaint of, “Well, what if we train these workers and then they leave?” is answered simply by German companies: “What if we don’t train them, and they stay?”

How U.S. policy should adapt

The policy team, as we call our mission participants, offered very specific recommendations for national policy adaptations that could have an impact.

This group suggests starting at the beginning by learning what actually works with individual students as they weigh their career options. Put simply, we need to better understand how the career choice process unfolds for young people. We just don’t know the major factors influencing young people’s occupational choices, so career awareness programs about manufacturing may be missing the mark. We also can and should create a more robust playbook of American companies that successfully leverage apprentices so we can be more efficient in sharing what’s working domestically. Once created, these playbooks should be disseminated widely. In short, scaling successful local partnerships should be a key goal for our policy experts.

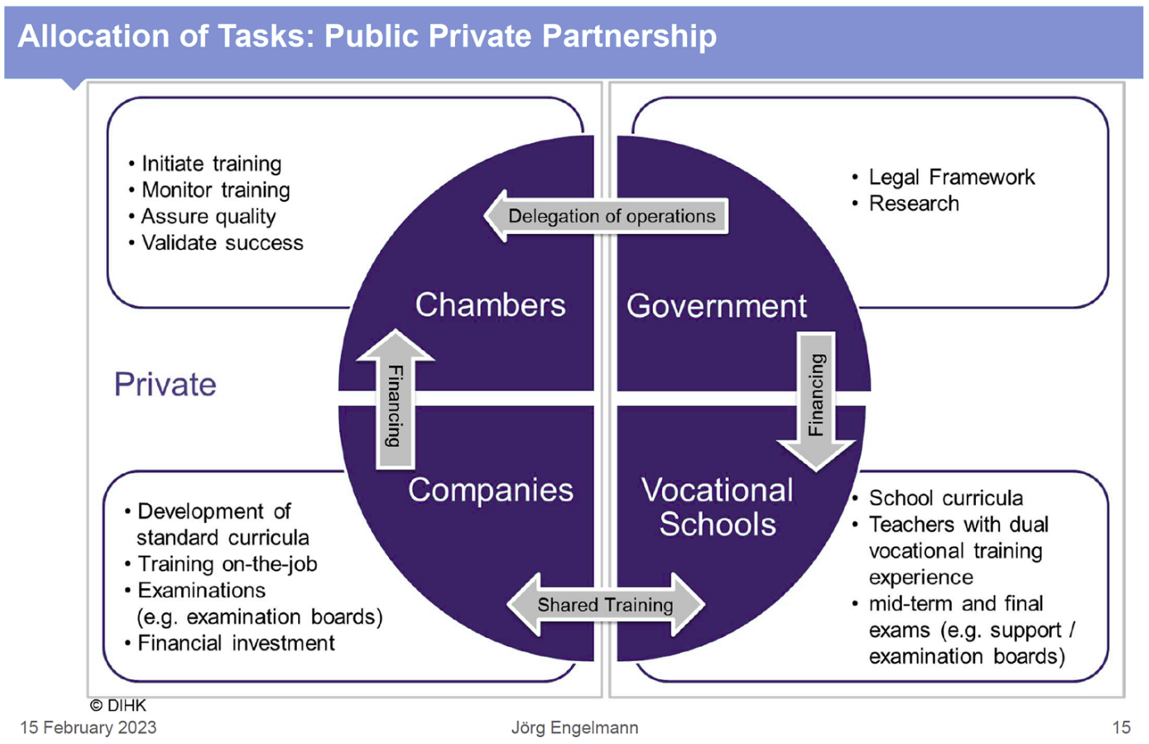

Next, we need to improve our existing system through clarifying the roles and responsibilities of those organizations involved in it. Together, German organizations reduce barriers for individuals and companies to participate in the VET system – there is a sense of pride and responsibility for all stakeholders to contribute to the system. The chart included here came from one of our German speakers. It contains three simple, but critical lessons for our existing stakeholders:

- There are clear roles and responsibilities for chambers of commerce, companies, vocational schools and the government.

- There is minimal overlap, which means each stakeholder knows its role and doesn’t compete with the others.

- There is a consistent and robust funding model that reinforces #1 and #2. Too often in the U.S. funding is available to anyone who applies. In Germany, the funding is directed and targeted with clear guidelines, so everyone stays in their lane and maximizes their existing funding.

Partnership and collaboration could also be emphasized across many U.S. government programs and departments: the MEP National Network, the Manufacturing USA institutes, the Department of Labor, the Department of Education, the National Science Foundation and more. This could eventually evolve into an entity focused on workforce best practices. Based on the German Fraunhofer Institutes, a public-private partnership devoted to workforce best practices may be what this country needs to truly move the needle on improving its manufacturing workforce.

Moving forward

MEP Centers can’t solve this problem alone. The German manufacturing industry works so well because there is a coordinated, aligned system focused on collective prosperity. Government, companies, vocational schools, and chambers of commerce sit down at the table at least quarterly to review and improve each vocation’s specific apprenticeship program.

MEP Centers can be that catalyst and facilitator for our local communities to embrace these changes.