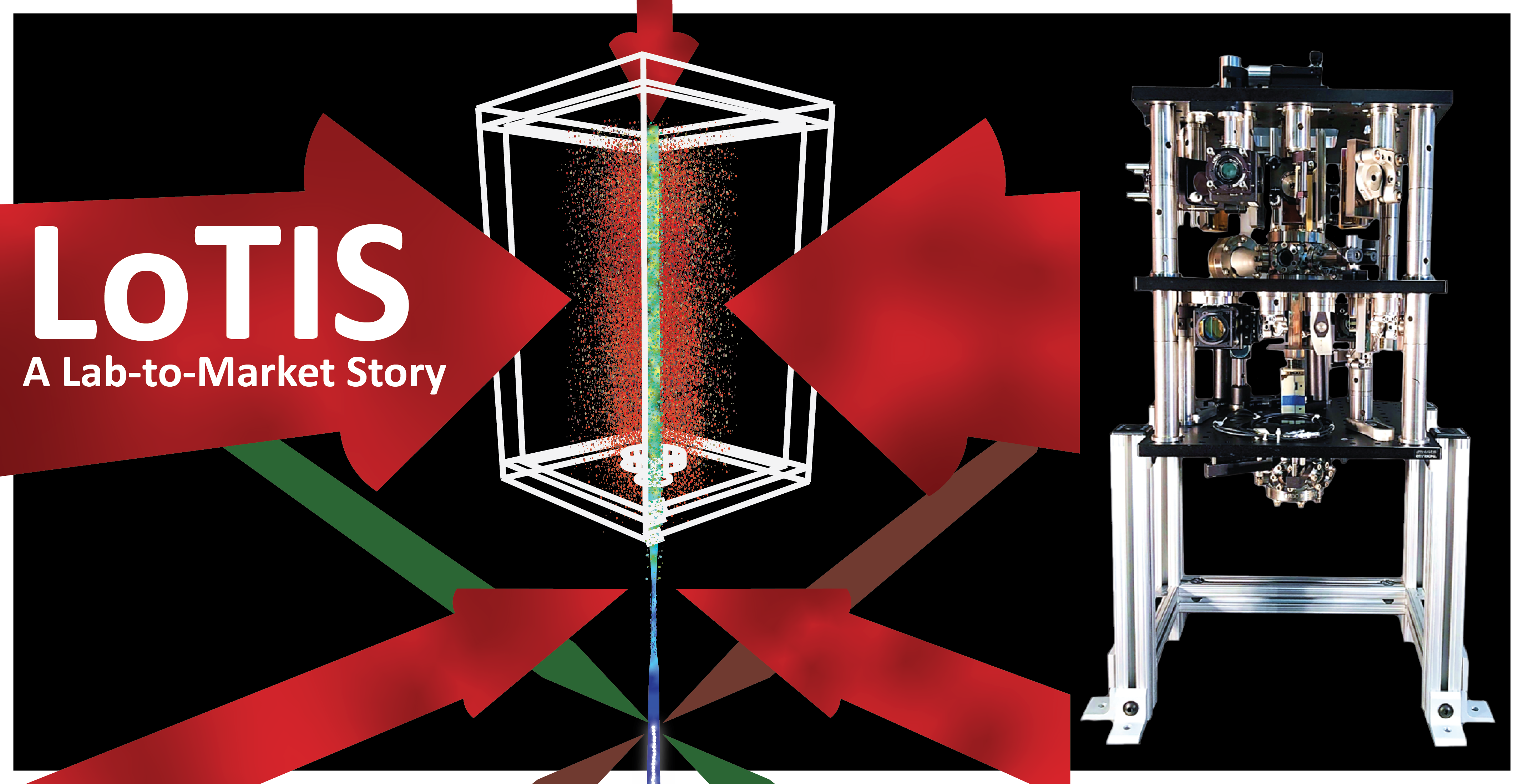

LoTIS: A Lab to Market story

Building upon the Nobel Prize-winning laser cooling techniques of NIST’s Bill Phillips, NIST physicist Jabez McClelland applied laser cooling techniques to the field of nanotechnology, where researchers work with structures 100 billionths of a meter or less in size. Using lasers to lower the temperature of atoms causes the atoms to move in a less random way, which enables the positioning of the atoms to be more precisely controlled.

Developing the LoTIS

In the mid-2000s, McClelland and his colleagues in the NIST Center for Nanoscale Science and Technology determined that ionizing, or electrically charging, the cold atoms would further improve the ability to place an atom at a desired location on the surface of a nanoscale object. They also calculated that an ionized cloud of laser-cooled atoms should make a high-brightness focused ion beam.

Focused Ion Beams (FIB) are an established technology. FIBs are used to carve minute patterns into materials, and to initiate chemical reactions that construct nanoscale features. They are also a standard tool in the semiconductor industry for “circuit-edit,” the in-situ rewiring of chips to test circuit modifications. However, the increasing demands for smaller nanoscale devices required more accurate FIB technology than was currently available on the market.

In 2012, McClelland and NIST post-doctoral researchers Adam Steele and Brenton Knuffman built the proof-of-concept Low-Temperature Ion Source (LoTIS) on display here. In 2013, this device demonstrated that their laser-cooled ion beam had a 10-fold improvement in sensitivity and precision over existing FIB technology.

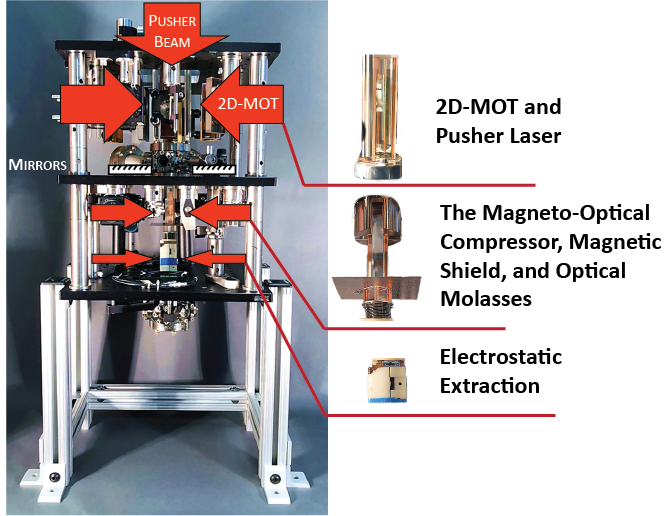

LoTIS Parts

2D-MOT and Pusher Laser: A set of laser beams gather room-temperature cesium atoms from the vacuum chamber, cool them down 300 K to ~ 3mK, and push them to the next stage.

The Compressor and Optical Molasses: Laser beams make the atom beam denser and further reduce its temperature another 3mK to ~30 uK.

Electrostatic Extraction: The ionized atoms are accelerated into an ion beam by a pair of steel plates to which voltage is applied.

Commercialization

At the end of their post-doctoral appointments in 2013, Steele and Knuffman formed a company to further develop LoTIS and commercialize the technology.

By 2017, the sensitivity and precision were increased to 24-fold using the next generation LoTIS prototype. As a new type of ion source, LoTIS brings improvements to a market that generated an estimated $600 million (2018) annually in economic activity.

Resources

- Steele, A. , Knuffman, B. and McClelland, J. (2014), New Ion Source for High Precision FIB Nanomachining and Circuit Edit, Proceedings of the International Symposium for Testing and Failure Analysis, Houston, TX, US, [online], https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=917117 (Accessed July 24, 2024) https://www.nist.gov/publications/new-ion-source-high-precision-fib-nanomachining-and-circuit-edit

- McClelland, Jabez. June 18, 2018. An Invention in Focus: When Science Gets Real. https://www.nist.gov/blogs/taking-measure/invention-focus-when-science-gets-real

Example of how to reference this exhibit:

NIST Museum. 2024. LoTIS: A Lab to Market story. Gaithersburg, MD: National Institute of Standards and Technology. Online. https://www.nist.gov/nist-museum/lotis-lab-market-story

Author. Year. Exhibit Name. Place published: Publisher. Online. URL.

Contacts

-

NIST Research Library & Museum(301) 975-3052