Summary

EPA Protocol gas mixture calibration standards are obtained by users to measure emissions of regulated gaseous species and ensure that they comply with US Environmental Protection Agency (EPA) regulations. These standards are produced by specialty gas manufacturers and supplied directly to users. The EPA Protocol Gas Verification Program (PGVP) conducts periodic audits to assess the accuracy of Protocol gases, which is an essential quality assurance (QA) component to assure the integrity of this program. NIST serves as the independent analytical laboratory for EPA audits. Samples of specified concentrations of nitric oxide (NO), sulfur dioxide (SO2), and carbon dioxide (CO2) in balance nitrogen (N2) are selected from all manufacturing sites. Six audits have been completed and NIST has developed a variety of analytical methods that achieved an analytical uncertainty of ≤0.5 %.

Description

Protocol gas standards are employed in measurements made for compliance purposes; one of the major uses is for measurements of regulated gaseous species from stationary source emitters, i.e., stack gases. Many of these stationary sources are regulated through the Cap and Trade program; therefore, accurate measurements are critical due to the economic and health consequences. EPA protocol gas mixture production is governed by Document EPA/600/R-12/531. Subsection 2.1.13 states that the EPA will periodically conduct audits of these gas mixtures, with a selection of at least two samples from every US manufacturing site. The samples are to consist of NO (25 µmol/mol to 1000 µmol/mol), SO2 (25 µmol/mol to 1000 µmol/mol), and CO2 (5 % mol/mol to 20 % mol/mol) in balance N2.

The objective of the audit is to determine whether the concentrations of the components of the gas mixtures are within the limits stated on the certificate provided by the vendor. The resulting data can be used to facilitate accurate reporting of continuous emissions monitoring (CEM) and stack measurements, to provide an independent quality check of the manufacturers, and to connect end users with reputable vendors. NIST has served as the independent analytical laboratory for audits since 2006. NIST has a stake in this process, as the gases and the measurements made using them are claimed to be NIST traceable.

In the 2006 PGVP audit, only 11 samples were received, and only 3 out of 17 vendors (6 of 37 manufacturing sites) were represented. In 2008, 87 samples were received and all 11 vendors (18 manufacturing sites) were represented. (The number of sites decreased due to industry consolidation.) In 2010, 57 samples were tested from 10 vendors (17 manufacturing sites). In 2013, 108 samples were tested from 11 vendors (22 manufacturing sites). In 2015, 116 samples were tested from 14 vendors (26 manufacturing sites). And in 2018, 66 samples were tested from 11 vendors (22 manufacturing sites).

The audit gas mixtures have three components: NO, SO2 and CO2, The presence of % mol/mol levels of CO2 changes the viscosity and molar mass of the audit gas, compared to single-component standards. It is important to ensure that such a change does not cause an unexpected bias in the analytical results. This bias is dependent on the analytical technique chosen and could also be subject to interference from one component to another.

NIST developed a variety of methods that achieved an analytical uncertainty of ≤0.5 % for NO, SO2, and CO2. The expected CO2 interference on chemiluminescence analysis was accurately modeled, as was the unexpected interference of pressure broadening (due to CO2) on nondispersive infrared (NDIR) and Fourier-transform infrared (FTIR) measurements.

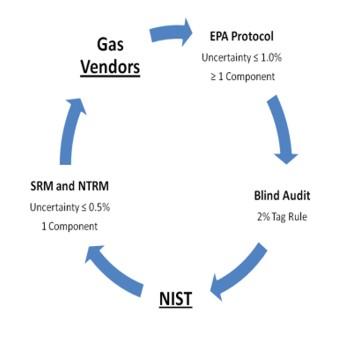

The figure illustrates the relationship between NIST and the Protocol gas vendors, with the uncertainty expressed as k = 1. If the analytical uncertainty claims of NIST (≤0.5 %) and the gas vendors (≤1.0 %) are valid, and either there is no bias (unexpected or expected) or the bias has been accurately corrected, then the difference between the NIST analysis and the vendor certified concentrations of the audit mixture should be ideally ≤1.0 % relative, and as a worst case no more than 2 % relative (2 % Tag Rule). The audit therefore validates the claims of traceability of the Protocol mixtures to NIST.

Major Accomplishments

- Completed multiple audits of EPA Protocol Gas standards containing NO, SO2, and CO2.

- Completed CCQM Key Comparison on emission gases that mimic the EPA protocol gas standards.

- Methods developed for analysis of NO (chemiluminescence, NDIR, NDUV, and FTIR), SO2 (NDIR, NDUV and FTIR) and CO2 (GC/TCD and NDIR) with an uncertainty ≤ 0.5%.

Associated Product(s)

US EPA (2012) “Traceability Protocol for Assay and Certification of Gaseous Calibration Standards” (PDF) (174 pp, 1.7 M, About PDF) Publication No. EPA/600/R-12/531.