Summary

We use autonomous experimentation to elucidate the role of composition, processing, and microstructure on the aqueous corrosion of complex metal alloys. To do this we are building a one-of-a-kind combined synthesis-characterization platform that is capable of making and measuring samples on demand. Our autonomous platform is meant to serve as a substrate for answering questions about trust and interpretability of modern AI systems, as well as bias and differences in human interpretation of data in materials science. Through this project we hope to lay the groundwork for autonomous experiments that answer scientific questions, which will be enabled by the future development of scientific AI imbued with materials science knowledge.

Description

Corrosion impacts a broad spectrum of application areas including infrastructure, transportation, and the military. The annual price tag for corrosion mitigation and remediation is 3.4 % of the US GDP. The team is particularly interested in discovering new metallic glasses (metals without long range atomic order) and high entropy alloys (solid-solution alloys containing multiple principal elements) for these applications.

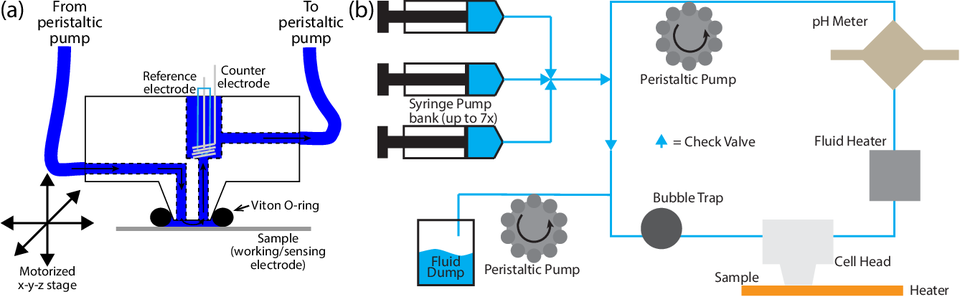

To accomplish our goals, we are developing a fully autonomous platform that permits the synthesis and multimodal characterization of novel corrosion resistant coatings whose composition, structure, and properties are predicted in real time by AI algorithms. The tool uses a scanning droplet cell connected to a liquid handling system to investigate the role of the environment (e.g., acidity, presence of chloride or fluoride ions) on alloy stability using standard corrosion tests such as Tafel analysis, measurements of the corrosion potential, and polarization measurements. We use a Gaussian Process modeling strategy to combine these corrosion measurements with online x-ray analysis of material structure and composition. This provides a comprehensive mapping of composition-processing-structure-performance relationships for every material measured, and predictions with quantified uncertainty for materials that are yet to be measured. Samples can either be traditional combinatorial libraries (deposited on 7.62 cm diameter wafers) or can be individually deposited on demand via electrodeposition immediately prior to characterization.

Our long-term goal is to lay the groundwork for autonomous experiments that answer scientific questions, which will be enabled by future development of AI imbued with materials science knowledge (“scientific AI”). This will involve the design of novel AI frameworks that can de novo incorporate the various physical models, heuristics, and intuitions that scientists combine to understand the world around them. For example, instead of directly modeling corrosion rates using black-box machine learning models, we could leverage the Butler-Volmer model of electrochemical kinetics, using AI to model the effects of structure and chemistry on the physical parameters of the Butler-Volmer model. This will move conventional AI in materials science from its current high-variance, poor extrapolation status quo, thereby strengthening the quality of extrapolative predictions and uncertainty estimates and creating physically interpretable models that bridge the existing AI - science trust gap.