Summary

The Bioprocess Sensing Group at NIST is investigating a range of fundamental and technological issues related to next-generation chemical and biochemical measurements with solid state devices. A significant portion of the research uses a basic micromachined platform, known as a microhotplate device to develop sensing materials and new methods for detection and quantitation of gases. The microhotplate contains a built-in heater, thermometer, and sensing film. It uses conductance changes in the sensing film to detect the presence of adsorbed gas species. Temperature changes may be used to alter the adsorption/desorption and reaction kinetics between the gas and sensor surface. Because of the small size, millisecond temperature changes in the range 20 °C to over 500 °C are used to create response "fingerprints" for different analytes. Surface analytical and microcharacterization methods are also used to investigate materials properties and mechanisms for sensing.

Description

A single micromachined microhotplate element for which the lateral dimension of the suspended structure is 100 microns. The structure is designed with an embedded resistive heater and surface electrodes for very rapid temperature control and electrical characterization of films deposited on it for sensing chemicals. Wafer-based fabrication allows arrays of these elements to be produced in which each element can be individually addressed for thermal programming and sensing measurements.

Our research is focused on the basic and applied aspects of chemical sensor science and technology in the following areas:

- The development and evaluation of nanoscale materials, e.g., nanowires and nanotubes, for high-performance chemical sensing of gas-phase species

- Novel approaches for low-cost, multi-analyte chemical monitoring technologies

- The signal processing approaches needed to identify and quantify in near real time a broad range of gas-phase chemical species in varying backgrounds

The research effort seeks to develop and integrate modular components of high-performance chemical sensors that include nanostructured sensing materials, multi-element microsensor arrays, advanced signal processing algorithms and novel sensor operational modes to yield a viable, generic and tunable sensor technology for broad application.

Approach

In materials research, we employed template-directed synthesis methods to prepare metal oxide nanotubes and nanowires. A novel sensor architecture based upon the nanotubes was prepared by using the template as a scaffold to support the nanotubes in a parallel alignment (Figure 1). Oxide nanowires, on the other hand, were released from their template and integrated with a microsensor array to compare them with a film-configured sensor as a function of sensor operating temperature and analyte. To compare the morphologically varied materials, we developed mathematical approaches involving cross-correlation techniques to visualize material- and temperature-dependent data that yield orthogonal information from chemical microsensor arrays.

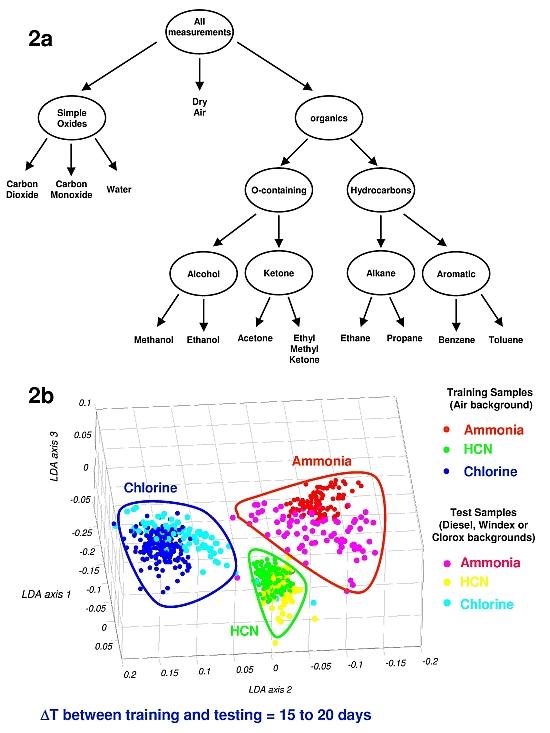

Inspired by biological approaches for processing high-density data streams, we have developed a hierarchical method for acquiring and analyzing sensor data. Unlike "all-at-once" methods of signal- processing, the new approach selects optimal portions of the data to answer a series of relatively simple analytical questions that become increasingly precise (Figure 2a). We have also developed an "Event-Detection" method that employs a two-step approach using high dimensionality data to first detect whether a chemical event (such as the introduction of a trace amount of a dangerous chemical) has occurred via correlation calculations, and then apply recognition algorithms to identify the chemical, if necessary. Linear discriminant analysis (LDA) demonstrates the separability of three target analytes in untrained backgrounds (Figure 2b).

Intended Impact

Higher sensitivity, stability, speed and reproducibility of sensing materials are critical to next-generation chemical sensing devices for gases. Furthermore, as sensors become more sophisticated and provide higher data density, advanced signal processing techniques become imperative for effectively making use of response data. Our research has yielded high sensitivity nanomaterials (nanotube assembly) used to fabricate sensors that gain sensitivity by a factor of 1000 over standard film-configured sensors. In signal processing, we have demonstrated two approaches for dealing with unknowns: analytes, which may be classified by their chemical functionality, and backgrounds, which may be ignored by using Event-Detection analyses. The synergistic use of these successes in nanomaterials, microsensor arrays, signal processing and operational modes are expected to impact many application areas, including alarm triggers for homeland security, trace gas detection in space exploration and the monitoring of gaseous, biologically generated compounds for medical diagnostics. Advanced microsensor arrays also hold the promise of enabling networked, low-cost microsensors to be used to detect and monitor low-concentration analytes in complex, dynamic backgrounds for a range of applications where the use of expensive instrumentation is not viable.

Major Accomplishments

- The development and demonstration of bio-inspired hierarchical and event-detection approaches to identify trace analytes in complex backgrounds

- The development and evaluation of high-performance sensors using 1D nanomaterials and cross-correlation techniques to evaluate their responses

We have developed a tunable array-based microsensor technology that involves robust and manufacturable components. The design is CMOS-compatible for the development of monolithic circuits.