Summary

Commercial metering systems are ubiquitous in the commercial marketplace (to dispense liquified products, from gas and water to food products and agricultural chemicals). Coriolis mass flow meters are being explored as the next generation of field test standards to evaluate the performance of such systems. NIST OWM has also established a NIST U.S. National Work Group (USNWG) on Field Reference Meters to provide a forum for working with the State weights and measure programs and industry stakeholders in this activity. The common goal is to develop uniform and appropriate legal metrology standards for this metering device technology and to harmonize, where possible, with other related national and international standard.

Description

Customers and businesses alike rely on metering systems to monitor and deliver their liquid-based commercial products (including a range of gas and fuels) consistently over time and across a range of locations. Weights and measures officials use several well-acknowledged field test standards to measure and verify the quantity fuel dispensed and indicated by commercial metering systems. This includes retail motor-fuel dispensers, loading rack meters, and liquefied petroleum gas metering systems.

Compressed Natural Gas (CNG) dispensers and some larger metering systems are typically tested gravimetrically, using a scale and a receiving tank to weigh the dispensed product. A gravimetric test method brings its own set of challenges – these can be time consuming and relatively inefficient; may be subject to environmental conditions (e.g., temperature, wind); and often require additional equipment and complex testing procedures. Often the remaining CNG gas (after weighment) is vented directly into the atmosphere; this is not only a wasteful practice, but it is negative implications for the environment. Some jurisdictions have also raised concerns about safety with regard to some of these practices.

For meters dispensing Liquefied Propane Gas (LPG) and other liquid fuels, calibrated volumetric, neck-type provers are most often used as test standards, but can also pose both reliability and practical challenges. For example, neck-type provers are not suitable for use in testing metering systems dispensing very viscous products due to the difference in drainage properties between those products and the fluid (typically water) used to test the standards in the laboratory. Furthermore, very large metering systems with high flow rates may be beyond the capacity of most commercially-available volumetric neck-type standards.

Coriolis Mass Flow Meters

These common hurdles described above have prompted State and local weights and measure programs to explore Coriolis mass flow meters as potential field test standards for verification of their measuring systems.

The sensor of a Coriolis mass flow meter contains a pair of vibrating U-shaped tubes with sensors on both ends. The frequency of the vibration is a measure for the density of the product flowing through the tubes. The phase shift between the vibration measured by the sensors at the end of the tubes is a measure for the flow rate of the product flowing through the tubes. Combining the measured product density and the measured flow rate, the mass flow meter is able to calculate the flow in mass per second, hence the name ‘mass flow meter’.

Besides the ability to simultaneously measure density and flowrate, Coriolis mass flow meters have a high degree of accuracy. Altogether, Coriolis mass flow meters are a viable alternative for conventional flow meter (e.g., turbine flow meters).

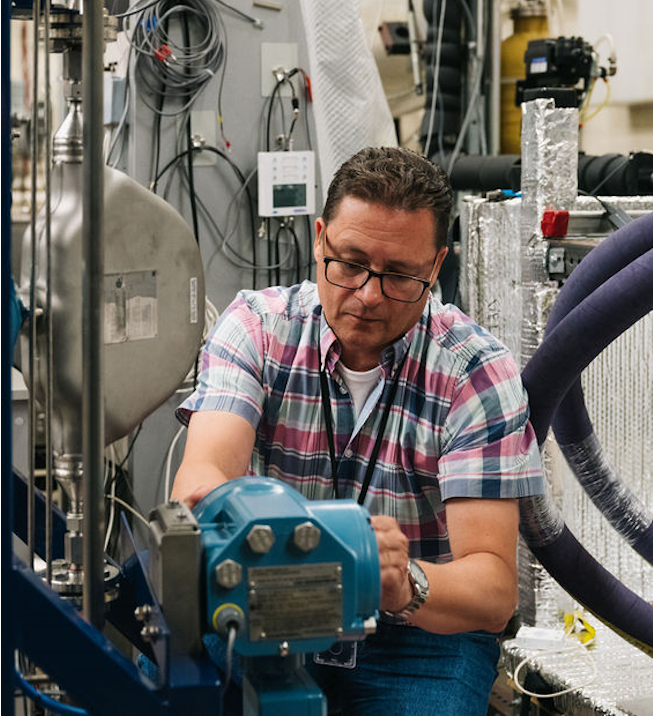

NIST OWM has responded by obtaining a series of Coriolis mass flow meters and is collaborating with weights and measures officials and industry to assess their potential use as test standards.

USNWG for Field Reference Meters

NIST has also established a NIST U.S. National Work Group (USNWG) on Field Reference Meters to collaborate with States and industry to demonstrate the utility of Coriolis mass flow meters as viable field test standards. This USNWG also provides a forum for the development of uniform and appropriate legal metrology standards for the appropriate operation of the mass flow meters under typical field operational conditions. As of June 2023, the USNWG includes 51 members representing 11 states and 7 industry organizations in addition to NIST and Measurement Canada. Membership in the USNWG has been inclusive and continues to remain open to any interested party.

The work of the USNWG on Field Reference Meters will include an assessment of whether or not mass flow meters can meet the criteria established in the Fundamental Considerations of NIST Handbook 44 for use as field test standards in testing commercial measuring systems. Harmonization with other related national and international standards is another important goal. The USNWG has created test protocols and spreadsheets for use in collecting data on the use of mass flow meters for testing CNG measuring systems and will develop similar tools for other applications, including LPG and loading-rack metering systems.

Participating states and their weights and measures staff have included the NIST mass flow meter in the test setup of their liquid fuel dispenser verifications. Some states are already experimenting with use of a mass flow meter for these field tests. In that case, the state’s mass flow meter is also included to provide additional information on different meters.