Additive Manufacturing

Applied Economics in US Manufacturing

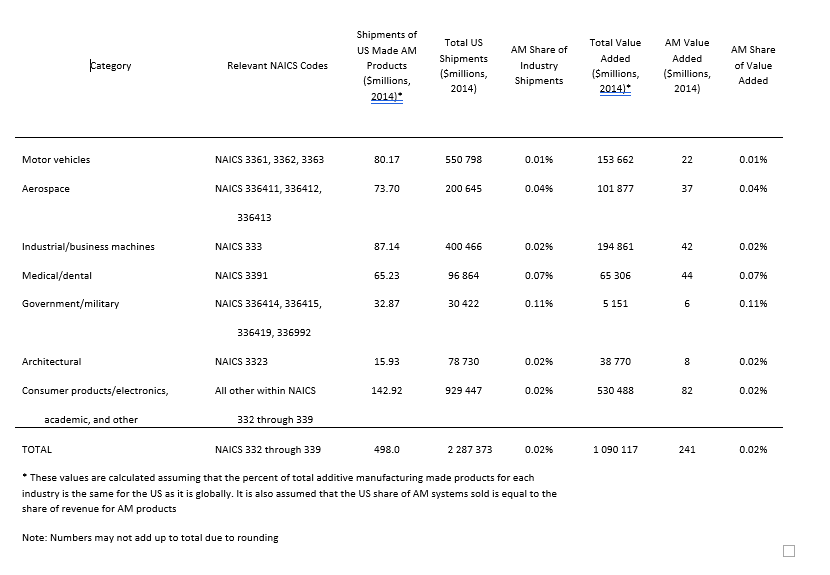

There are three primary aspects to the economics of additive manufacturing: measuring the value of goods produced, measuring the costs and benefits of using the technology, and estimating the adoption and diffusion of the technology. Globally, there is an estimated $667 million in value added produced using additive manufacturing, which equates to 0.01 % of total global manufacturing value added. US value added is estimated as $241 million (see table below); however, the use of this technology is growing rapidly. Current research on additive manufacturing costs reveals that it is cost effective for manufacturing small batches with continued centralized production; however, with increased automation distributed production may become cost effective. Due to the complexities of measuring additive manufacturing costs and data limitations, current studies are limited in their scope. Many of the current studies examine the production of single parts and those that examine assemblies tend not to examine supply chain effects such as inventory and transportation costs along with decreased risk to supply disruption. The additive manufacturing system and the material costs constitute a significant portion of an additive manufactured product; however, these costs are declining over time. The current trends in costs and benefits have resulted in this technology representing 0.02 % of the relevant manufacturing industries in the US; however, as the costs of additive manufacturing systems decrease, this technology may become widely adopted and change the supplier, manufacturer, and consumer interactions. An examination in the adoption of additive manufacturing reveals that for this technology to exceed $4.4 billion in 2020, $16.0 billion in 2025, and $196.8 billion in 2035 it would need to deviate from its current trends of adoption. A number of AEO publications on the economics of additive manufacturing are listed below.

Costs and Cost Effectiveness of Additive Manufacturing

This report examines literature on the costs of additive manufacturing and seeks to identify those instances where additive manufacturing might be cost effective and also identify potential means for reducing costs when using this technology. Current research on additive manufacturing costs reveals that this technology is cost effective for manufacturing small batches with continued centralized manufacturing; however, with increased automation distributed production may become cost effective. Due to the complexities of measuring additive manufacturing costs, current studies are limited in their scope. Many of the current studies examine the production of single parts. Those that examine assemblies tend not to examine supply chain effects such as inventory and transportation costs along with decreased risk to supply disruption.

Economics of the US Additive Manufacturing Industry

Additive manufacturing may provide an important opportunity for advancing U.S. manufacturing while maintaining and advancing U.S. innovation. Additive manufacturing is a relatively new process where material is joined together layer by layer to make objects from three-dimensional models as opposed to conventional methods where material is removed. The U.S. is currently a major user of additive manufacturing technology and the primary producer of additive manufacturing systems. Globally, an estimated $642.6 million in revenue was collected for additive manufactured goods, with the U.S. accounting for an estimated $246.1 million or 38.3 % of global production in 2011. Change agents for the additive manufacturing industry can focus their efforts on three primary areas to advance this technology: cost reduction, accelerating the realization of benefits, and increasing the benefits of additive manufacturing. Significant impact on these areas may be achieved through reduction in the cost of additive manufacturing system utilization, material costs, and facilitating the production of large products. There is also a need for a standardized model for cost categorization and product quality and reliability testing.

Costs, Benefits, and Adoption of Additive Manufacturing: A Supply Chain Perspective

This paper reviews the literature on additive manufacturing costs, identifies those instances in the literature where additive manufacturing is cost effective, proposes an approach for examining the total advantage of additive manufacturing, and discusses trends in the adoption of additive manufacturing. Current research on additive manufacturing costs reveals that this technology is cost effective for manufacturing small batches with continued centralized manufacturing; however, with increased automation distributed production may become cost effective. Due to the complexities of measuring additive manufacturing costs, current studies are limited in their scope.

Economics of Additive Manufacturing (Book Chapter)

There are three aspects to the economics of additive manufacturing. The first involves measuring the size of additive manufacturing. This includes measuring the value of the goods produced using this technology in the context of the total economy. The second aspect involves measuring the costs and benefits of using this technology. It includes understanding when additive manufacturing is more cost effective than traditional manufacturing and why it is more cost effective. It also involves understanding other advantages such as new products that might not be possible with traditional manufacturing. The last aspect of additive manufacturing economics is the adoption and diffusion of this technology. Additive manufacturing is significantly different from traditional methods; thus, determining when and how to take advantage of the benefits of additive manufacturing is a challenge in and of itself. Manufacturers have to invest resources into understanding whether additive manufacturing makes sense for their business. If they adopt this technology, they will have to train or hire employees who are able to utilize it. This chapter is not intended to be a comprehensive review of these issues, but rather it provides an introduction into each of the topics.

Adding it Up: The Economic Impact of Additive Manufacturing

This news report from the Intelligence Unit of The Economist features research and interview material from NIST staff and research on additive manufacturing.

Contacts

-

(301) 975-4918