Summary

The information provided in this report will support a more realistic assessment of fires in electrical enclosures and the overall impact of material composition on key burning behaviors of interest to fire safety scientists and engineers. Beyond the direct observations and experimental measurements obtained for this specific test configuration, this study also offers a comprehensive set of validation data for computational fluid dynamics (CFD) simulations of large-scale fire growth due to flame spread over the surface of combustible solids.

Description

Volume 1

Experimental Observations of the Burning Behavior of Combustible Solids in Parallel Panel Configuration at Full-Scale (NIST Technical Note 2282)

Report Summary

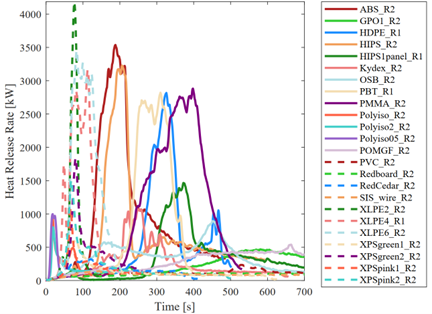

This report provides an overview of measurements (e.g., heat release rate, gaseous species production, and flame-to-surface heat transfer) and visual observations obtained from a series of 66 full-scale fire growth experiments conducted on 18 unique combustible solids including: natural and synthetic polymers, copolymers, fiberglass-reinforced composite materials, porous polymer foams, and electrical cables. Some of these materials were selected because they can be found in electrical cabinets and circuit boards. Others were selected in order to provide a wide range of material compositions (i.e., chemistries) and burning behaviors: physical deformation (e.g., swelling, charring collapse, dripping, and/or melt flow), heavy or light soot formation, and varied ignitability and fire growth rate.

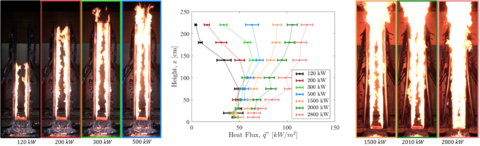

In a typical electrical enclosure, combustible solids (e.g., wiring or circuit boards) are most often found attached to the inside walls. A test setup was thus selected to represent this configuration: two parallel panels (2.44 m tall by 0.61 m wide) were assembled such that they could support combustible solids of varying thicknesses (each spaced 0.30 m apart), which were then ignited at their base. This simplified configuration ensured:

the production of a large-scale burning scenario representative of typical fuel loading in an electrical enclosure, and

that the experiments could be repeated to highlight the impact of material composition on observed burning behavior (e.g., ignitability, fire growth rate, and peak fire size) while minimizing test sensitivity to variations in other factors such as fuel loading (e.g., wire packing density), configuration, or orientation.

Download Measurement Data

Key measurement devices were incorporated into this test apparatus in order to measure the primary mechanism controlling fire growth (flame-to-surface heat transfer during upward flame spread over the surface of the combustible solids) and to measure global quantities characterizing fire behavior and development: heat release rate (HRR), soot and gaseous species (i.e., CO and CO2) yields. Additionally, video of each experiment was recorded by at least two video cameras and photographs were taken throughout each experiment.

Heat Release Rate (HRR) and Species Yield measurement data and videos recorded during these experiments are available online on the NIST Fire Calorimetry Database [1]: https://www.nist.gov/el/fcd/vertical-upward-flamespread-parallel-panels.

Flame heat flux measurement data is available online:

Time-resolved measurements of flame heat flux: heatflux_time-resolved.zip

Time-resolved measurements of heat flux gauge temperature: HFG_Temperature_time-resolved.zip

Spatially-resolved measurements of flame heat flux: heatflux_spatially-resolved.zip

Summary of Measurement Data

Fire Size (Heat Release Rate, HRR)

Peak HRR: 110 kW to 4186 kW

Time to Peak HRR: 16 s to 1022 s after burner exposure

Total Heat Release: 16 MJ to 566 MJ

Heat of Combustion: 9.6 kJ/g to 39.9 kJ/g (energy release per gram of fuel burned)

Species Yields

Soot yield [g/g]: Below Detectable Limits to 0.21

CO yield [g/g]: 0.004 to 0.42

CO2 yield [g/g]: 0.62 to 3.6

Heat Transfer

Peak, total flame-to-surface heat transfer: 71 kW/m2 to 254 kW/m2

Fraction of total wall flame heat flux attributed to radiation: 11 % to 69 %

Peak radiation heat flux at a distance (~3.6 m from panels): 0.02 kW/m2 to 7.72 kW/m2

Volume 2

Bench-Scale Measurements for Material Property Calibration (Ongoing Work)

Additional volumes of this report will include bench-scale measurements conducted on all 18 materials presented in this work, including (1) thermogravimetric analysis (TGA), (2) differential scanning calorimetry (DSC), (3) microscale combustion calorimetry (MCC), and (4) pyrolysis of coupon sized slabs in an anaerobic (nitrogen) environment when exposed to well-characterized radiant heating. The data will be used to derive material properties controlling heating, decomposition, and production of gaseous volatiles.

Collectively, the measurement data obtained from each of these experiments (from bench- to full-scale) will provide a comprehensive set of measurement data needed to calibrate pyrolysis models for combustible solids (i.e., determine relevant material properties), use these material property sets for quantitative prediction of fire growth using CFD tools, and validate the simulation results.