WHO WE ARE

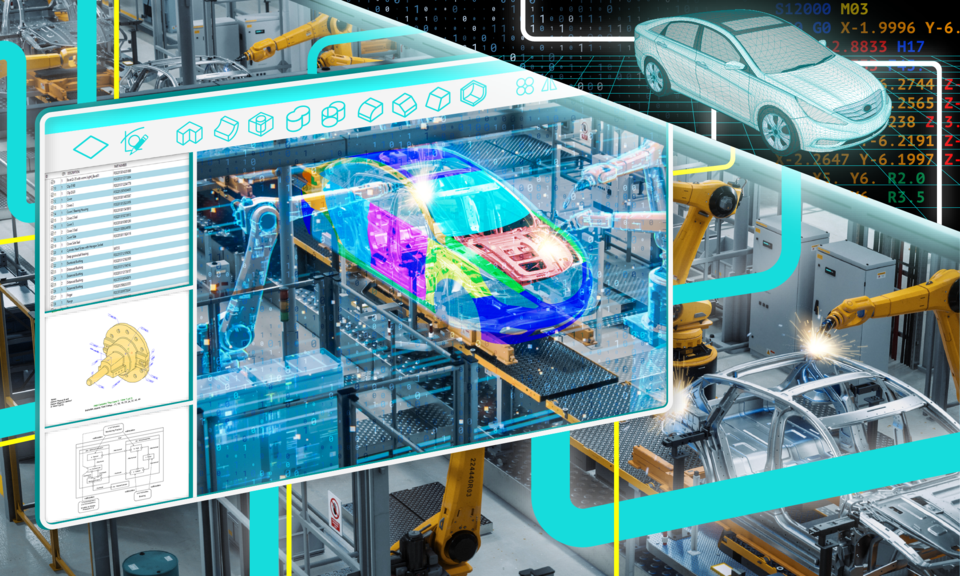

The Smart Connected Manufacturing Systems Group conducts research with the objective of helping US manufacturers make the transition to model-based practices through innovations in systems modeling, integrating analysis into systems models, establishing a trusted, standards-based digital thread for lifecycle data, exploration of heterogeneous data fusion, guidelines for industrial AI best practices, and guidelines for evaluating industrial AI systems.

CURRENT PROJECTS

- Systems Analysis Integration, Project Lead Conrad Bock.

- Develops methods, protocols, and standards enabling efficient integration of systems models and engineering analysis models, to facilitate design, manufacture and maintenance of smart infrastructure and manufacturing systems.

- Digital Thread, Project Lead Allison Barnard Feeney.

- Delivers methods, protocols, and tools that enable U.S. manufacturers to use universal digital models to connect systems and communicate trusted product and process data, improving quality, reliability, interoperability, and efficiency.

- Industrial AI Metrology and Management, Project Lead Michael Sharp.

- Improves understanding and effective use of AI systems and tools for industrial applications through the development of domain-specific applications management and methods for qualitative and quantitative systems measurement.

News and Updates

Projects

Software

Contacts

Group Leader

-

(301) 975-2433