High Throughput (Combinatorial) Screening Tool for Characterization of Thin Film Thermoelectrics as a Function Temperature

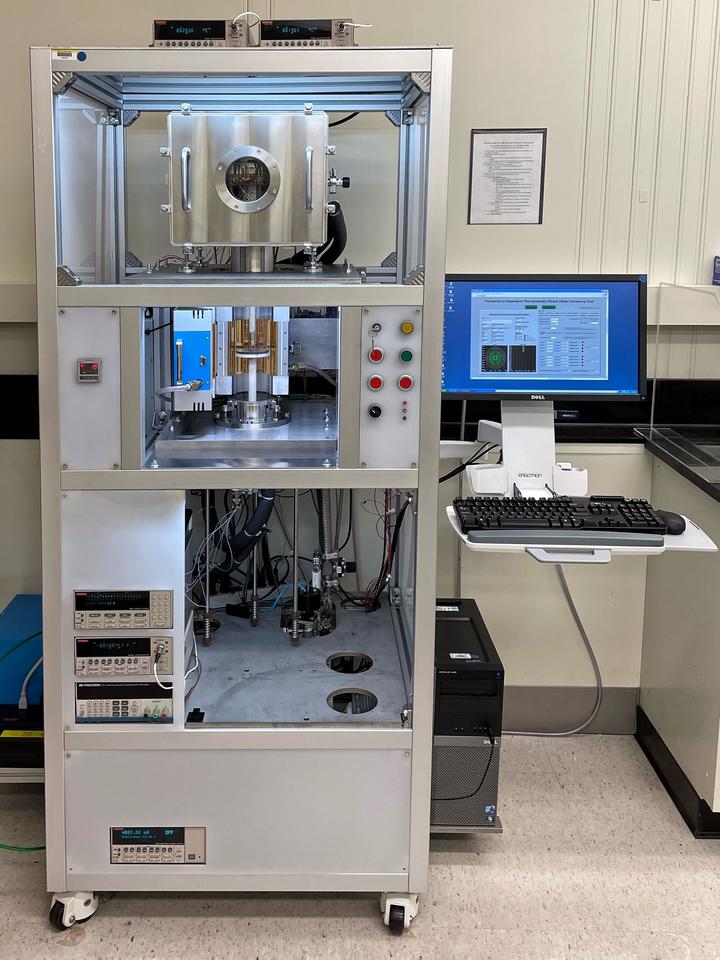

Photograph of the custom high temperature (>300 K) scanning instrument that measures electrical resistivity and Seebeck coefficient on thin film, combinatorial, and composition spread materials.

Description

High-throughput (combinatorial) metrologies have evolved as a useful approach to rapidly determine the composition-structure-property relationships for novel materials systems as compared to the traditional one-composition-at-a-time approach. For such measurements, the combinatorial library, typically a composition-spread film, is synthesized and then characterized by high throughput measurement techniques for composition, structure and other selected properties of interest. Thus, two essential types of tools are needed: one for composition spread library film synthesis, and the other for screening of the desired property or characteristic. The success of this method applied to thermoelectric (TE) research relies on screening tools to evaluate the TE properties for a combinatorial library.

Our thermoelectric screening tool can perform temperature dependent measurements of the Seebeck coefficient, and electrical resistivity, from 300 K to 800 K. The principle of the measurement is similar to the “hot probe” technique. In this technique, a thermocouple probe is heated by a miniature heater and brought into contact with the sample surface; a local thermal gradient will be generated in the vicinity of the “hot probe”, while another thermocouple (the “cold probe”), also in contact with the surface, is placed away from the hot probe. The Seebeck coefficient is measured using a pair of independently spring-loaded Type R thermocouple probes spaced 3 mm apart, using the quasi-steady state condition of the differential method. A small rising temperature difference is applied to the film using a heater element embedded in one of the thermocouple probes. The thermoelectric voltage and temperature difference are measured simultaneous using 3 nanovoltmeters to eliminate correspondence distortion errors. The Seebeck coefficient is calculated as the slope of the unconstrained linear fit of the voltage and temperature difference ordered pairs, where R2 ≥ 0.95. The measured Seebeck coefficient is then subtracted from the absolute Seebeck coefficient of the platinum reference wires to obtain the corrected Seebeck coefficient of the film. The sheet resistance is measured using a square array of four, 0.65 mm spaced, hand-polished tungsten wires mounted in a spring-loaded 4 bore alumina tube and using the 4 point probe technique. Correction factors are calculated for the relationship of the probe spacing/film diameter ratio and the displacement of the probe from the center of the film. Eight resistance permutations are measured to correct for probe asymmetry and for Seebeck coefficient contributions to the resistive voltage that can arising from Joule heating of the film. These permutations are used to iteratively solve for the sheet resistance. The electrical resistivity is then calculated by multiplying the sheet resistance and the film thickness.

Specifications/Capabilities

- Measures the Seebeck coefficient and electrical resistivity from 300 K to 800 K

- Measures composition spread films up to 76.2 mm diameter and bulk materials of arbitrary dimension

- Vacuum and helium gas atmosphere capable