About Lightweighting

The use of lightweight alloys in vehicles will significantly increase fuel efficiency and cut emissions, but the auto industry lacks data and material models needed to reliably manufacture vehicle components from lightweight metals, including aluminum alloys and high-strength steels. Upon surveying our partners in the automotive and steel industries, we determined that NIST can meet a key role in addressing this problem by developing new mechanical testing methods and metrology, as well as a fundamental understanding of the interplay between multiaxial strain behavior and sheet microstructure.

Approach

We are developing a technique where the sheet's stress-strain response can be measured along non-linear multiaxial paths. This provides unique data on how the multiaxial flow surface changes with plastic strain, and this can be used to modify materials models used by industry. Concurrently, we also measure the evolving crystallographic texture of the sheet and the surface roughness, to develop a microstructural understanding of the materials' deformation response.

Accomplishments

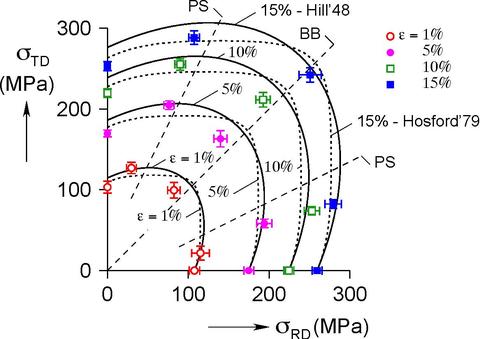

The tensile multiaxial yield surface of 5754 aluminum alloy sheet was measured from initial yield up to failure for the first time. The initial shape of the surface closely approximates an ellipse, as predicted by most plasticity models for forming. However the balanced biaxial strain path results in unequal biaxial stresses, contrary to the plasticity models. At the highest strains the biaxial stresses become balanced. Also of note is that the plane strain behavior is not symmetric between the rolling and transverse directions.

On the same samples, the crystallographic texture evolves from a rolling texture to one of the predominant FCC deformation textures, as expected. Unexpectedly, the deformation texture that develops when the sheet is deformed in the rolling direction (RD) differs from that which develops during deformation in the transverse direction (TD).

The two deformation textures are 90 degree rotations with respect to one another, but the twofold symmetries of the textures leads to an asymmetry in the stress needed to form the textures, which coincides with the measured asymmetry in the yield surface. These results are being modeled using a Taylor-type description of the flow behavior of polycrystalline aggregates undergoing evolving textures, which is the basis of many common plasticity models, to see if this formulation adequately captures the behavior.

Contacts

-

(301) 975-5703