Nanoscale Reliability Group

The Nanoscale Reliability Group develops and disseminates science, standards, and technology for high-resolution measurements of material structure, chemistry, and physical properties, to ensure reliability of materials and devices with critical dimensions in the micrometer to nanometer regime.

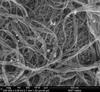

The performance of advanced, reliable engineering materials requires that the proper atoms are in the correct place within the material, and that the material displays the properties we intend. Innovative metrologies are developed and demonstrated in the realms of electron, ion, and scanned probe microscopies, to identify and locate atomic species, and to determine physical responses of materials. Test structures, measurement methods, and in situ testing approaches are developed to measure performance of complex material systems and geometries with high spatial resolution, enabling new reliability physics to be applied to nanoscale structures for electronics, structural material, and energy applications. We integrate material characterization metrologies with material performance and reliability assessments.

Recent Group Highlights

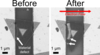

Callie Higgins, a Materials Research Engineer in the Nanoscale Reliability Group, has won the FY21 Service to America Emerging Leaders award for her work in ensuring the reliability of polymeric materials created by 3D printing and in early career staff advocacy. She is one of seven medal winners selected from across the entire Federal government. Read the NIST News Release here. Read and listen to her story from the Federal News Network here.

News and Updates

GROUP PATENTS

NIST encourages patent protection on inventions when a patent would further the interests of U.S. manufacturing, increase the potential for current or future commercialization or use of the technology, would likely to lead to a license, would have a positive impact on a new field of science or technology and/or the visibility and vitality of NIST, or would further the goals of collaborative agreements.

Although patents are issued in the name of the inventor, the rights to inventions resulting from government work belong to the government. NIST's Technology Partnerships Office negotiates licensing of patented NIST technology.

Sample holder, detector mask, and scope system for analytical transmission scanning electron microscopy

9,970,859; 9,746,415

Imaging spectrometer for extreme ultraviolet atom probe tomography

10,153,144; 9,899,197

Electron vibrometer for atomic force microscopy

10,060,946

Projects and Programs

Publications

Awards

Press Coverage

|

Name

|

Phone

|

Email

|

Primary Project |

|---|---|---|---|

| Benjamin Caplins | (303) 497-6703 | benjamin.caplins [at] nist.gov (benjamin[dot]caplins[at]nist[dot]gov) | |

| Ann Chiaramonti Debay | (303) 497-5701 | chiaramonti [at] nist.gov (chiaramonti[at]nist[dot]gov) | Extreme Atom Probe Tomography |

| Jacob Garcia | (303) 497-3976 | jacob.garcia [at] nist.gov (jacob[dot]garcia[at]nist[dot]gov) | Extreme Atom Probe Tomography |

| Callie Higgins | (303) 497-5991 | callie.higgins [at] nist.gov (callie[dot]higgins[at]nist[dot]gov) | Photopolymer Additive Manufacturing |

| Jason Holm | (303) 497-4335 | jason.holm [at] nist.gov (jason[dot]holm[at]nist[dot]gov) | Analytical Transmission Scanning Electron Microscopy |

| Bob Keller | (303) 497-7651 | bob.keller [at] nist.gov (bob[dot]keller[at]nist[dot]gov) | |

| Jason Killgore | (303) 497-4729 | jason.killgore [at] nist.gov (jason[dot]killgore[at]nist[dot]gov) | |

| Thomas Kolibaba | (303) 497-5811 | thomas.kolibaba [at] nist.gov (thomas[dot]kolibaba[at]nist[dot]gov) | Photopolymer Additive Manufacturing |

| Elisabeth Mansfield | (303) 497-6405 | elisabeth.mansfield [at] nist.gov (elisabeth[dot]mansfield[at]nist[dot]gov) | Electronic Material Characterization |

| Ryan White | (303) 497-3938 | ryan.white [at] nist.gov (ryan[dot]white[at]nist[dot]gov) |

Contacts

Group Leader

-

(303) 497-7651