In a few weeks, NIST will begin offering a new, state-of-the-art calibration service for accelerometers. Based on a technique called laser interferometry, the system will be sensitive enough to detect motion over distances as small as a few nanometers (the size scale of a single molecule) and frequencies up to 50,000 cycles per second (50 kHz).

Richard Allen explains how NIST calibrates accelerometers using a precision "shaker table" that vibrates the devices over a range of distances and frequencies. Running the video at full-screen size will improve view of detail. Video by Jennifer Lauren Lee.

Accelerometers, which detect changes in motion, are perhaps most familiar as the sensors that tell your mobile phone screen to rotate or determine whether automotive airbags should deploy based on how abruptly the car's speed changes. They are also the basis of handheld remote controllers for motion games sold by Nintendo and other companies.

But accelerometers have long been essential to the automotive and aerospace industries for identifying unwanted vibrations, to the military for inertial guidance* of submarines and weapons systems, to seismologists who study the motion of the earth, and to facilities such as nuclear power plants to provide early warning that a piece of equipment is about to fail.

"These days, they're increasingly being used everywhere, not just in smartphones but also in wearable devices such as fitness trackers and watches" says Michael Gaitan, project leader in NIST's Nanoscale Metrology Group. "They are what provide the information used by the apps that tell you how much you're moving around, so you can count your calories."

Potential uses abound. There is intense interest in combining inertial guidance with GPS for position locations in places where GPS signals cannot reach, such as inside buildings. "They have to be accurate enough that you can use them for a reasonable period of time when a GPS signal is not available," Gaitan says.

In addition, researchers studying traumatic brain injury need increasingly accurate ways to measure shock, and engineers are examining better ways to embed vibration sensors in bridges and buildings to warn of possibly unsafe conditions.

The utility of these and other applications depends critically on the accuracy of the accelerometers. Calibrating them reveals how well they can measure the distance something moves (the "throw") over a specific amount of time, how fast it can respond to that change, and whether its readings vary over time, among other considerations.

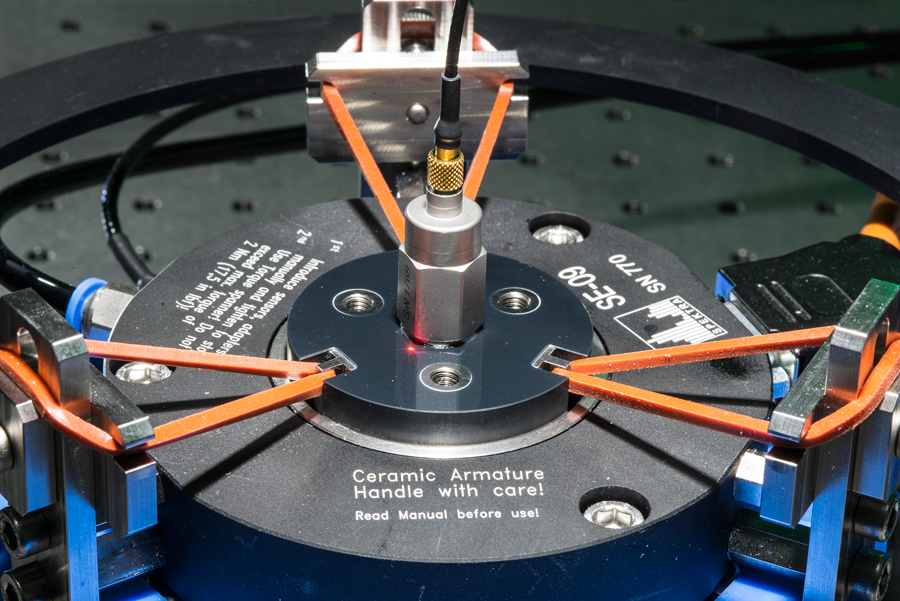

In NIST's facility, as in many others, measurements are made on a shaker table – a small platform that is vibrated at specific frequencies over specific distances. For a typical accelerometer about the size of a lipstick tube, a simple test run might take about 10 minutes to step the device from about 5 cycles per second (5 Hz) with a throw of about 8 millimeters to 25 kHz (the facility's initial upper limit for calibration measurements) at which frequency the plate moves only a few percent of the width of a human hair.

The table's motion is continuously monitored – without physical contact – by a downward-pointing laser beam from a device called a vibrometer, which is mounted on a 200-pound base plate above the shaker. The system very accurately monitors the shaker table's vibration frequency and displacement by detecting the way that laser-light waves, when reflected off the table surface, reinforce or cancel each other back at the vibrometer's sensors. The data are then compared to the output readings from the accelerometer under test over a span of approximately 1 m/s2 to 100 m/s2.

To measure the performance of accelerometers over much lower frequencies, which require longer throw distances, the NIST facility also contains two other instruments—mounted on a cubic meter of granite – that allow for motion over as much as 50 mm.

Although project researchers sometimes work collaboratively with manufacturers, the principal customers for the service will be calibration laboratories, many of which have contracts that call for NIST-traceable measurements, as well as large facilities such as nuclear plants that require periodic verification of sensors in safety systems.

When planning how to upgrade their calibration capabilities to meet the latest demands, the project scientists decided against building a full custom apparatus. Instead, they chose to obtain the kind of commercially available, high-tech system used at the world's top metrology institutes.

NIST's new primary calibration system is custom made to stringent NIST-required specifications. At present, the researchers are finishing a complete suite of tests on the system, and will soon publish the uncertainty budget – an analysis listing all possible sources of uncertainty in different aspects of the measurements, and the relative magnitudes of each. So far, they have determined that the system performance exceeds the manufacturer's claimed specifications. This finding, subject to further testing, may enable NIST's calibration service to lower its uncertainties even further as in the future.

"Although acceleration calibrations have been conducted at NIST and the world's other national measurement institutes since the 1960s, a new wave of microsensor technologies is driving new consumer portable technologies and are poised to be a prime application of the internet of things,"** Gaitan says.

"These applications are driving high-volume sensor manufacturing, resulting in a $15 billion world market with a 13% compound annual growth rate. It is projected to grow to $22 billion by 2018. The testing and calibration requirements of these sensors are becoming more complex and demanding as more functions, such as gyroscope and compasses, are integrated together with the accelerometers. NIST is working together with the sensor manufacturing industry to advance measurement technologies and standards to meet these needs."

Note: Any mention or image of commercial products within NIST web pages is for information only; it does not imply recommendation or endorsement by NIST.

* Inertial guidance uses motion sensors to determine the location of an object by tracking its path from a well-defined starting point.

** The "internet of things" refers to the rapidly expanding number of applications in which embedded computing devices communicate with one another over the Internet.