Summary

The widespread use of robots in flexible factories (i.e., factory environments subject to high product turnover, short production runs, and high variability in equipment configurations) is limited by the robots’ inability to safely collaborate with one another and with human labor. The robots’ incapacity to coordinate, communicate, and understand their actions, roles, and task statuses thus decreases the robots’ usefulness in applications where tasks cannot be completed by a single robot. This limitation is driven by both the absence of tools and protocols needed for describing collaborative functions, and the complete lack of metrics for assessing how we expect robots to work with other robots and with humans. The Performance of Collaborative Robot Systems project will provide the methods, protocols, and metrics necessary to evaluate the collaborative capabilities of robot systems, and will use a task-driven decomposition of manufacturing processes to assess and assure the safety and effectiveness of human-robot and robot-robot collaborative teams toward the manufacturing performance objectives. This collection of methods, protocols, and metrics will enable end-users to maximize the effectiveness and efficiency of integrating collaborative robots into their production processes, impacting both large-scale companies designing and repurposing fully autonomous manufacturing workflows, and smaller companies looking to begin automating existing processes performed largely by manual labor.

Description

Objective: Deliver a suite of test methods, protocols, and information models to assess and assure that robots working collaboratively in human-robot and robot-robot teams will complete their assigned tasks safely and correctly while meeting their assembly performance objectives.

Technical Idea: To achieve the specified objective, the Performance of Collaborative Robot Systems project will focus on developing a collective metrology suite consisting of test methods, metrics, systems models, software libraries, and algorithms to evaluate the robots’ capabilities that contribute to the successful completion of collaborative tasks. This collective metrology suite will enable end users of collaborative robot technologies to:

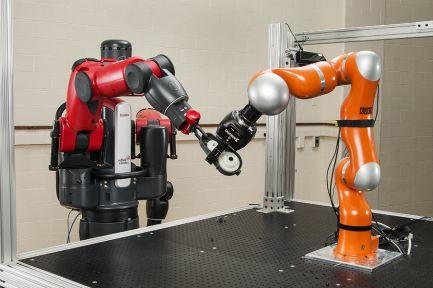

- Integrate, coordinate, evaluate, and optimize heterogeneous robot workcells (i.e., robots of different makes and models working together) consisting of robotic arms, hands, and mobile platforms using the test methods and metrics developed by this project. \

- ssess and optimize the motions of multiple robots to minimize negative impacts on motion timing, path trajectory efficiency, and structural integrity of workpieces, tooling, and the robots themselves using the test methods, metrics, and systems models developed by this project.

- Employ robots capable of collectively, intuitively, and safely deviating from programmed paths using explicit and implicit coordination methods to accommodate for robot, human, part, and obstacle location and orientation uncertainty using the algorithms and metrics produced by this project.

- Share and receive instructions, status updates, and diagnostic data using methods intuitive to the members of the collaborative team (e.g., audible or visual feedback for human teammates, and structured status messages for robot teammates) using this project’s resulting models, metrics and software libraries.

- Automatically allocate roles and responsibilities to multiple robot or human team members based on capabilities, expected performance, safety considerations, and availability using the algorithms and systems models developed by this project.

- Provide more intuitive plug-and-play capabilities in heterogeneous, multi-robot, collaborative teams where physical and process state representations of the different robot systems are incompatible. Information mined from communications can be used to validate, augment, and correct world models, and enable enhanced situational awareness and safety for collaborative robots.

- Assess and assure the efficiency and effectiveness of employing collaborative robots in flexible factory environments such that the costs and benefits of integrating robots into collaborative teams are optimally balanced in favor of the end user (or, in the event that collaborative teams are sub-optimal, provide justification for more traditional robot installations).

Research Plan: This research plan focuses on five principal capabilities of robot systems that collectively contribute to collaborative teams: 1) temporal and spatial coordination of robot, 2) task role and responsibility decomposition, allocation, and comprehension, 3) developing protocols for robot-robot and human-robot collaboration communications, 4) validating the cognitive awareness of collaborative robot systems, and 5) assessing and assuring the collective performance of teams containing collaborative robot systems. Each of these foci builds upon the capabilities defined or developed in its predecessor. Collectively, they will comprise a total suite of test methods, metrics, and protocols to assess the collaborative performance of robot systems. For each phase of development, the test methods, metrics, and protocols will be evaluated using the NIST collaborative robotics testbed.

- Coordination performance: We will deliver test methods and metrics for evaluating the coordinated performance of independently-controlled robot systems. These test methods and metrics will be developed through a focused engineering process, including a literature review and platform specific research and development. We will focus on both explicit (control-negotiated) and implicit (sensor-based) coordination, and will present metrology that characterizes temporal and spatial control uncertainties, and measures the impacts of synchronization errors.

- Comprehension performance: We will deliver hierarchical models of collaborative assembly task decompositions consisting of human and robot role representations and assignments. The process of the hierarchical model building will be based on methodologies for task decompositions and representations for human-robot task safety. We will leverage existing task decomposition methods when feasible, and will generate new methodologies when necessary. Role allocations and responsibilities will feed into state machines that guide robot motions and higher-level task planning. A library of parameterized motion primitives for multi-robot assembly will also be developed to support ease-of-programming and process diagnostics.

- Communication performance: We will deliver test methods for assessing robot-robot and human-robot collaboration communications of high-level, task-relevant information. Associated prototype robot messaging protocols will also that enables timely and actionable process instruction and diagnostics.

These protocols will be developed based on an assessment of the needs, hardware and software mechanisms, and capabilities of robots and humans to formulate and exchange information with one another. Metrics for assessing effectiveness of communications in human-robot interactions will also be compiled, and will provide feedback for manufacturers and systems integrators with subjective and objective feedback regarding operator effort and situational awareness, as well as the impacts the human-machine interfaces have on the manufacturing processes and human-robot team dynamics.

- Cognition performance: We will deliver test methods to validate a robot’s situational awareness of a collaborative assembly task. To accomplish this, we will construct numerical models that register the dissimilar physical and state representations, identify the similarities and differences between them, and then compare both with a ground truth to compensate for errors or gaps. Metrics and protocols for evaluating interfaces for safety systems and human position and intent tracking will feed into the situational awareness models will also be developed.

- Cooperative performance: We will deliver test methods that measure the conformance of human-robot and robot-robot collaborative teams to protocols, information models, and performance expectations for assembly tasks. The results of the previous four robot capability research efforts will be merged to form a suite of tools that will collectively assess the collaborative performance of collaborative robot systems working in human-robot and robot-robot teams. Metrology for evaluating, verifying, and validating the impacts of integrating robots into collaborative teams will be produced, and will provide insights into the costs and benefits of human-robot and robot-robot collaborations.