Summary

Additive manufacturing (AM) uses digital designs to fabricate three-dimensional products that are built up layer by layer. This process, also known as 3D printing, can produce complex designs using less material and generating less waste than traditional manufacturing. Comprehensive measurements and standards are critical for expanding AM use by industry. Through its core missions of measurement science research and standards development, the National Institute of Standards and Technology (NIST) is working with U.S. industry to lead these manufacturing transitions.

What is Additive Manufacturing?

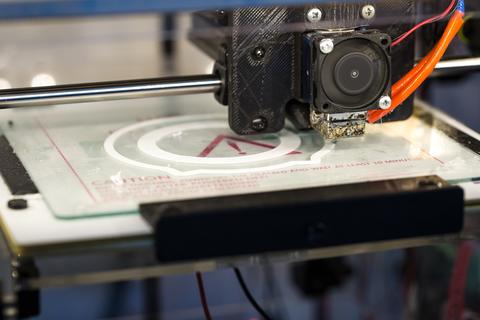

Additive manufacturing (or 3D printing) fabricates parts by building them up layer-by-layer (as opposed to cutting material away or molding it). The field shows great promise for a diversity of applications, from lightweighting aerospace structures to creating customized biomedical implants. 3D printing is one of several approaches to additive manufacturing (AM).

The image on the left shows the scrap generated from traditional manufacturing and the image on the right shows how AM builds parts layer by layer.

How Does Additive Work?

Metallic, plastic, or ceramic materials are typically laid down one thin layer at a time and placed precisely as directed by a digital design file. The raw materials are often in the form of powders or wires that can be melted and shaped by a laser.

An example application for the medical industry would be an artificial jawbone. A 3D computer model of a jawbone is created based on the patient's bone structure, and this model is sliced into many layers. The computer then feeds the information into the additive machine, which could generate the complex bone structure substitute out of metal.

Why NIST?

Additive manufacturing is causing fundamental changes in the way mechanical parts are produced. As the field matures, comprehensive measurements and standards will be critical for expanding AM use by industry. Through its core missions of measurement science research and standards development, NIST is working with U.S. industry to lead these manufacturing transitions.