An official website of the United States government

Here’s how you know

Official websites use .gov

A .gov website belongs to an official government organization in the United States.

Secure .gov websites use HTTPS

A lock (

) or https:// means you’ve safely connected to the .gov website. Share sensitive information only on official, secure websites.

Projects

The National Institute of Standards and Technology (NIST) Material Measurement Laboratory (MML) Additive Manufacturing Program (AM) studies the fundamental behaviors of materials under various conditions. From this materials research, MML AM produces additive manufacturing reference standards to support U.S. commerce, competitiveness, and manufacturing.

The following are MML AM projects dedicated to the metrology of AM materials (metals, polymers, ceramics, & biomaterials). Feel free to contact us with questions or opportunities to collaborate.

Metals, Polymers, Ceramics, and Biomaterials

Click the plus icons (+) below to learn about our research in metals, polymers, ceramics, and biomaterials.

Additive Manufacturing Fatigue and Fracture

Metal additive manufacturing is not used in fatigue and fracture critical applications despite industrial need. The goal of this project is to enable confident use of metal AM in critical applications through several methods. Read more.

Project Leader: Nik Hrabe

Additive Manufacturing of Metals

Additive Manufacturing of Metals (AMOM) and its subprojects enable new pathways for innovative materials design of additively manufactured metal alloys through a foundation of materials science, measurement science, and data science that focuses on localized and in situ measurements of process-structure-property-performance relationships at relevant time and length scales. Read more.

- AMOM Accelerated AM Alloy Design

Project Leaders: Carelyn Campbell & Samantha Webster - AMOM Composition Sensitivity

Project Leader: James Zuback - AMOM Mechanical Characterization

Project Leaders: Lyle Levine & Saadi Habib - AMOM Performance of AM-Processed Alloys

Project Leader: Mark Stoudt

Advanced Materials Design: Structural Applications

The current project focus is on the development of high temperature Co-based superalloys, the development of new materials specifically designed for AM processing, and the optimization of currently used AM materials. Read more.

Project Leader: Carelyn Campbell

Multifunctional 3D Printable Polymer-Metal Composites

Our goal is to support innovation and fundamental research in additive manufacturing of multifunctional materials with low energy consumption, facilitating the transition from cutting-edge materials science to future AM technologies for multifunctional 3D hierarchical metallic and composite structures. Read more.

Project Leader: Ran Tao

Additive Manufacturing Benchmark Test Series

Additive Manufacturing Benchmark Test Series (AM Bench) provides a continuing series of AM benchmark measurements, challenge problems, and conferences with the primary goal of enabling modelers to test their simulations against rigorous, highly controlled additive manufacturing benchmark measurement data. Read more.

Project Leader: Lyle Levine

Hierarchical Materials

This program seeks to develop fundamental structure-property measurements to support advanced manufacturing of a new class of composites. Our focus is on damage resistant materials with long term performance. Read more.

Project Leader: Zois Tsinas

Multifunctional 3D Printable Polymer-Metal Composites

Our goal is to support innovation and fundamental research in additive manufacturing of multifunctional materials with low energy consumption, facilitating the transition from cutting-edge materials science to future AM technologies for multifunctional 3D hierarchical metallic and composite structures. Read more.

Project Leader: Ran Tao

Photopolymer Additive Manufacturing

NIST's goal is to support innovation in the photopolymer additive manufacturing (PAM) industry by enabling unprecedented high-resolution, mechanically-precise vat photopolymerization via fundamental understanding informed by novel voxel and sub-voxel-scale characterization throughout all major stages of the printing process. Read more.

Project Leaders: Jason Killgore & Callie Higgins

Polymer Additive Manufacturing and Rheology

We develop instrumentation and methodologies for measurement of temperature and stress fields in polymeric materials and their real-time material responses. We focus on measurements where national needs have been identified, such as plastics recycling and composite curing, and in emerging areas that represent sources of new U.S. manufacturing, such as additive manufacturing. Read more.

Project Leader: Anthony Kotula

Additive Manufacturing Benchmark Test Series

AM Bench provides a continuing series of AM benchmark measurements, challenge problems, and conferences with the primary goal of enabling modelers to test their simulations against rigorous, highly controlled additive manufacturing benchmark measurement data. Read more.

Project Leader: Lyle Levine

Additive Manufacturing of Ceramics

Additive manufacturing of ceramics seeks to facilitate the commercialization of ceramics AM via the concurrent development of new measurement approaches, characterization, and computational methods for ceramic materials. Read more.

Project Leader: Russell Maier

Biofabrication of Tissue Engineered Constructs

In the field of tissue engineering, 3D scaffolds and cells are often combined to yield constructs that are used as therapeutics to repair or restore tissue function in patients. Our project developed a noninvasive, label-free, 3D optical coherence tomography (OCT) method to rapidly image large sample volumes to assess cell viability and distribution within scaffolds. Read more.

Project Leaders: Carl Simon & Greta Babakhanova

Point-of-Care Pharmaceutical Manufacturing & Precision Medicine

Advancements in manufacturing technologies can aid the move from few rigid centralized pharmaceutical manufacturing facilities toward many agile distributed manufacturing and point-of-care (POC) manufacturing facilities to enable personalized and precision medicine. Read more.

Project Leaders: Thomas Forbes & Greg Gillen

Additive Manufacturing of Ceramics

Additive manufacturing of ceramics seeks to facilitate the commercialization of ceramics AM via the concurrent development of new measurement approaches, characterization, and computational methods for ceramic materials. Read more.

Project Leader: Russell Maier

Photopolymer Additive Manufacturing

NIST's goal is to support innovation in the Photopolymer Additive Manufacturing (PAM) industry by enabling unprecedented high-resolution, mechanically-precise vat photopolymerization via fundamental understanding informed by novel voxel and sub-voxel-scale characterization throughout all major stages of the printing process. Read more.

Project Leaders: Jason Killgore & Callie Higgins

Polymer Additive Manufacturing and Rheology

We develop instrumentation and methodologies for measurement of temperature and stress fields in polymeric materials and their real-time material responses. We focus on measurements where national needs have been identified, such as plastics recycling and composite curing, and in emerging areas that represent sources of new U.S. manufacturing, such as additive manufacturing. Read more.

Project Leader: Anthony Kotula

Biofabrication of Tissue Engineered Constructs

In the field of tissue engineering, 3D scaffolds and cells are often combined to yield constructs that are used as therapeutics to repair or restore tissue function in patients. Our project developed a noninvasive, label-free, 3D optical coherence tomography method to rapidly image large sample volumes to assess cell viability and distribution within scaffolds. Read more.

Project Leaders: Carl Simon & Greta Babakhanova

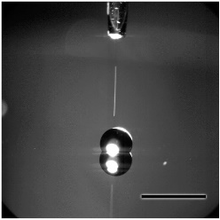

Inkjet Printing and Precision Deposition

The ability to deposit small amounts of material in a highly controllable and precise fashion helps create test materials for trace detection methods for a variety of chemical compounds and aids instrument development. Material microdeposition can enable delivery of chemical compounds for health care purposes, e.g., vaccines, small molecules, and drugs. Read more.

Project Leader: Michael Verkouteren

Photopolymer Additive Manufacturing

NIST's goal is to support innovation in the Photopolymer Additive Manufacturing (PAM) industry by enabling unprecedented high-resolution, mechanically-precise vat photopolymerization via fundamental understanding informed by novel voxel and sub-voxel-scale characterization throughout all major stages of the printing process. Read more.

Project Leaders: Jason Killgore & Callie Higgins

Point-of-Care Pharmaceutical Manufacturing & Precision Medicine

Advancements in manufacturing technologies can aid the move from few rigid centralized pharmaceutical manufacturing facilities toward many agile distributed manufacturing and point-of-care (POC) manufacturing facilities to enable personalized and precision medicine. Read more.

Project Leaders: Thomas Forbes & Greg Gillen

Additive Manufacturing of Ceramics

Additive manufacturing of ceramics seeks to facilitate the commercialization of ceramics AM via the concurrent development of new measurement approaches, characterization, and computational methods for ceramic materials. Read more.

Project Leader: Russell Maier

Additive Manufacturing Fatigue and Fracture

Metal additive manufacturing is not used in fatigue and fracture critical applications despite industrial need. The goal of this project is to enable confident use of metal AM in critical applications through several methods. Read more.

Project Leader: Nik Hrabe

Polymer Additive Manufacturing and Rheology

We develop instrumentation and methodologies for measurement of temperature and stress fields in polymeric materials and their real-time material responses. We focus on measurements where national needs have been identified, such as plastics recycling and composite curing, and in emerging areas that represent sources of new U.S. manufacturing, such as additive manufacturing. Read more.

Project Leader: Anthony Kotula

Contacts

MML Additive Manufacturing Program Coordinator

-

(303) 497-5991