Invent Calendar

- Sun

- Mon

- Tues

- Wed

- Thur

- Fri

- Sat

AC Radio Receiver (Patent 1,455,141)

Year Granted: 1923

Inventors: Percival D. Lowell and Francis W. Dunmore

Plug it in: Meet the first commercially built broadcast radio receiver that operated with alternating current (AC) delivered by the power grid (at 60 hertz).

In the early years of radio broadcasting, radio receivers were powered exclusively by batteries. The periodic need to change the batteries was inconvenient, to say the least. Batteries at that time were bulky, heavy, cumbersome and an acid-filled source of danger and damage in a household.

Our researchers showed that receivers could use household 110-volt AC without sacrificing performance quality. Using AC household current to power radio sets was much safer and more convenient for the consumer, which helped to expand radio ownership and propel the growth of the radio and broadcasting industries.

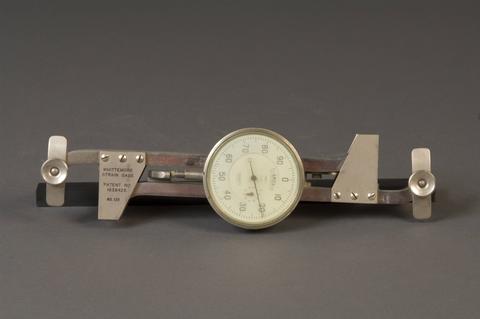

Whittemore Strain Gauge (Patents 1,638,425 and 2,177,605)

Years Granted: 1927-1939

Inventor: Herbert L. Whittemore

At the request of the Engineering Foundation in the mid-1920s, mechanical engineer Whittemore created this gauge to measure strains on structural pieces (such as bridge trusses) over long periods of time, even under adverse conditions in the field.

Fun fact: The instrument was also used to measure the reinforcement for the dome of the Smithsonian Institution’s Natural History building.

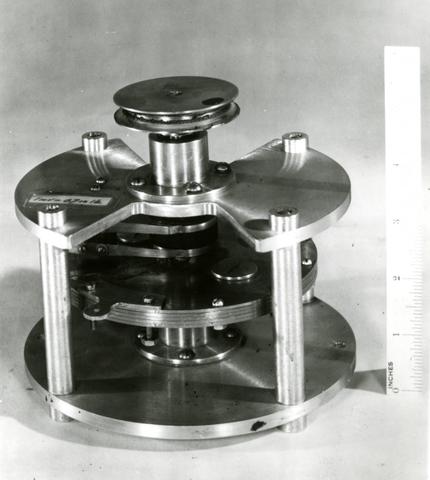

Proving Ring (Patents 1,648,375 and 1,927,478)

Years Granted: 1927-1933

Inventors: Herbert L. Whittemore and Serge N. Petrenko

Growing construction and industrialization in the U.S. after the Civil War, along with the birth of aviation, prompted the need to better test lightweight materials for machinery and buildings before use. Otherwise, projects could end in explosions, building collapses and other mishaps. Our researchers determined that a test used at the end of World War I for measuring the hardness of materials, the Brinell Hardness Test, yielded inaccurate results due to differences in force measurements from one lab to another.

After early successes using deadweight machines to measure force more consistently, the researchers created the proving ring (shown here) so that equally accurate measurements could be achieved outside of the lab and in the field. Proving rings are still produced and in use today.

Knoop Identifier (Patent 2,091,995)

Year Granted: 1937

Inventor: Frederick Knoop

In the 1930s at NIST (then known as the National Bureau of Standards), researcher Knoop developed a test for measuring the hardness of materials using this indenting instrument. At the time, it was the only testing equipment capable of making a hardness comparison between the softest and hardest materials, such as wax and diamond.

The Knoop hardness test is still used today.

Spiral Contractometer (Patent 2,568,713)

Year Granted: 1951

Inventors: Abner Brenner and Seymour Senderoff

When a metal is coated with a substance via electrodeposition, excessive internal stress can cause that coat to peel, blister or crack. The damage to the coating can, in turn, cause the metal itself to corrode. This device measured the internal stress while the metal was in the process of being coated. It was used for research and production in the plating industry.

Magnetic Particle Clutch (Patent 2,575,360)

Year Granted: 1951

Inventor: Jacob Rabinow

With a mixture of light lubricating oil and powdered carbonyl iron inside a chamber connecting two free-spinning plates, the magnetic particle clutch allowed precise torque control in multiple fields. It was used in Renault and Subaru automobiles in Europe and Japan, in airplane controls and in the disk file of the IBM RAMAC computer.

Inventor Rabinow used a model autobus equipped with a magnetic fluid clutch and a magnetic fluid brake to demonstrate the potential use of the magnetic fluid principle for automotive clutches.

Flexometer (Patent 2,603,083)

Year Granted: 1952

Inventor: Herbert F. Schiefer

This instrument helped researchers evaluate the physical properties of fabrics that affected stiffness and creasing, which in turn affected a fabric’s “feel” and “drape.” In addition to cloth, this tool was used to measure other materials such as paper, sheet rubber and patent leather.

Telephone Call Indicator (Patent 2,813,154)

Year Granted: 1957

Inventor: Jacob Rabinow

Dares don’t always spur good results, but this one did. This device was born from a challenge presented by Rabinow’s patent attorney during a long car trip. Could this mechanical engineer create an inexpensive device to indicate whether a telephone call had rung even if nobody had been there to answer it? (This was before the creation of answering machines and voicemail, by the way.)

Rabinow crafted a device that would operate with a principle similar to one he saw in childhood: A wooden toy bulldog would jump out of its doghouse box when stimulated by a clap or yell, operating on a closed circuit between a battery and electromagnet that would open briefly when a loud sound vibrated the box. With Rabinow’s invention, the telephone ring would stimulate a jump in voltage that would cause a neon light to shine. Neon caused the light to shine even after the sound ceased and the circuit closed, so someone coming back later would notice that a call had been received.

Conveyor Belt Card Sorter (Patent 2,961,093)

Year Granted: 1960

Inventor: Jacob Rabinow

All census work at the U.S. Census Bureau until 1948 was carried out via millions of punched cards. Most of the machines used to sort the cards would separate them into 12 stacks, but the Census Bureau wanted to sort into as many categories as necessary and, in the 1940s, turned to NIST (then known as the National Bureau of Standards) for a solution. To meet the need, mechanical engineer Rabinow developed this conveyor belt card sorter, which could sort at a rate of 420 cards per minute.

Rabinow turned out to be one of the most creative and prolific inventors ever to work for the United States government, even building on this invention to create a patent for his private company that helped the U.S. Post Office code and sort mail. Watch our video to get to know this practical man a little better.

Diamond Anvil Device (Patent 3,079,505)

Year Granted: 1963

Inventors: Charles E. Weir, Alvin Van Valkenburg and E.N. Bunting of NIST, and Ellis R. Lippincott of the University of Maryland

This device squeezed a finely powdered sample material into a film between the flat surfaces of two gem-cut diamonds to help researchers study the effects of high pressures on molecular interactions.

At the time (and still today), diamonds could get expensive, and it might have been hard to justify taxpayer dollars for the invention. To bring this idea to fruition, researchers used diamonds confiscated by the U.S. government from international smugglers.

Radio Frequency Radiation Monitor (Patent 3,750,017)

Year Granted: 1973

Inventors: Ronald R. Bowman, Ezra B. Larsen, and Donald R. Belsher

In response to a need from the National Institute for Occupational Safety and Health in the early 1970s, researchers at NIST (then known as the National Bureau of Standards) worked to develop a simple yet reliable method to accurately measure occupational exposure to electromagnetic radiation from industrial radio frequency power sources. Shown here is a prototype model of an electromagnetic radiation field survey monitor developed as part of this project.

Three and Five Axis Laser Tracking Systems (Patent 4,714,339)

Year Granted: 1987

Inventors: Kam Lau and Robert Hocken

This instrument uses a laser to measure the distance and angle of a moving target, and it’s the first laser tracking interferometer combined with a servo system to do so. Three-dimensional measuring systems such as this are now essential for large-scale precision manufacturing, particularly in aerospace, where laser trackers have almost completely replaced traditional techniques for measuring and accurately assembling airplanes.

Neutron Absorbing Glass Compositions (Patent 5,221,646)

Year Granted: 1993

Inventors: Douglas H. Blackburn, Craig Stone, David C. Cranmer, Dale A. Kauffman and James Grundl

To support experiments at the NIST Center for Neutron Research, our researchers developed a neutron-absorbing glass material that would not release gamma rays. This glass is still made at NIST and used at the NCNR today, often to shield instruments from thermal neutrons.

Three Degree-of-Freedom Telescoping Geometry Scanner (Patent 6,600,553)

Year Granted: 2003

Inventor: William C. Stone

Remember the laser tracker from a few days ago on the Invent Calendar? Have another one! This laser scanner has a 360-degree rotating sensor head and extendable mast system, which can be especially helpful for measuring geometrical features inside of nuclear power areas without contamination problems. While the sensor remains outside of a contaminated area, the mast system can be extended into the space.

Method and Apparatus for Artificial Weathering (Patent 6,626,052)

Year Granted: 2003

Inventors: Joannie Chin and Jonathan Martin

NIST’s SPHERE (aka Simulated Photodegradation via High Energy Radiant Exposure) puts materials through the wringer, mimicking days, weeks or years of exposure to the elements. A high-intensity ultraviolet light source at the center of the machine can generate 60 times the irradiance levels of the Sun. The light shines inside chambers on the periphery of the device where samples are held. There, temperature and humidity can be precisely controlled. Even today, our researchers use the machine to break down specimens, exploring everything from building materials to electrical cables, and solar panels.

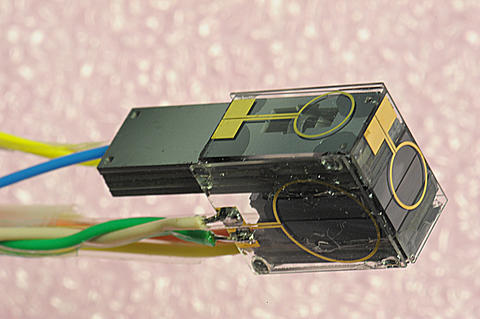

Atomic Magnetometer and Method of Sensing Magnetic Fields (Patent 8,334,690)

Year Granted: 2012

Inventors: John Kitching, Vladislav Gerginov, Svenja Knappe, and Jan Preusser

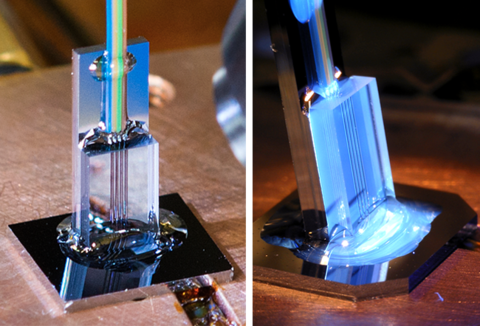

The brain and heart produce magnetic fields caused by electrical currents, and detecting those fields can help with diagnoses of medical conditions such as epilepsy and cardiac dysfunction. Cue NIST’s chip-scale magnetometer, which operates without directly touching the skull or disturbing the brain. This compact device passes small beams of laser light through a chamber containing a vapor of alkali atoms. If it’s in the presence of a magnetic field, the spin orientations of the atoms change, and the outgoing laser beam does too.

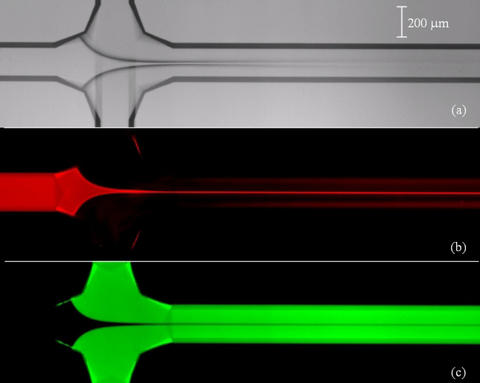

Controlled Vasicle Self-Assembly in Continuous Two Phase Flow Microfluidic Channels (Patent 9,198,645)

Year Granted: 2015

Inventors: Andreas Jahn, Wyatt Vreeland, Laurie Locascio and Michael Gaitan

What if doctors could deliver anti-cancer drugs directly to tumors without making patients sick? NIST researchers brought the dream of targeted drug delivery closer to reality for pharmaceutical manufacturers with today’s patent.

The NIST method employs microfluidics, the use of fluids at the microscopic level, to create precise nanoscale spherical capsules made of lipids (the kinds of biomolecules that also comprise fats). Essentially, the capsules are simplified artificial versions of cell membranes, the outer coverings of cells. The inside could hold drugs, and the outside could be coated with receptors that bind to specific cancer cells.

Optical Temperature Sensor (9,726,553)

Year Granted: 2017

Inventors: Zeeshan Ahmed, Stephen Semancik, Jacob Taylor, Haitan Xu, Jingyun Fan, Greg Strouse and Mohammad Hafezi

Our modern world depends on accurate and rapid temperature measurements. Most sensors used are based on a temperature-dependent resistance measurement of a strain-free metal wire or thin film, but these are sensitive to environmental conditions and mechanical shock, and may drift over time.

Consider the photonic temperature sensor an ultra-sensitive alternative. This device works by manipulating light's interaction with structures etched into a chip. It’s low-cost, lightweight, portable and resistant to the interference of magnetic and electrical fields. From controlled laboratory conditions to a noisy factory floor to private residences, this thermometer can handle its surroundings.

Photonic thermometry is part of the NIST on a Chip program, which seeks to unleash American innovation with technologies that can be deployed nearly anywhere and anytime, without the need for periodic calibration.

Aerodynamic Shoe Sampling System (9,983,102)

Year Granted: 2018

Inventors: Stefan Lukow and Matthew Staymates

If you enjoy long lines and wait times to get through security at airports, you might not be a fan of this invention. Using high-pressure air jets and air knives, our aerodynamic shoe sampling system removes and collects small particles from footwear without the need for physical contact. That means law enforcement authorities could still accurately test for trace amounts of explosives and narcotics, but people moving through security checkpoints wouldn't have to remove their shoes.

Authentication Article and Process for Making Same (Patent 10,152,666)

Year Granted: 2018

Inventors: Yaw S. Obeng, Joseph J. Kopanski and Jung-Joon Ahn

Counterfeit products entering the supply chain are a big problem for our security and safety, affecting all manufactured items, from electronics to pharmaceuticals. Detecting the fakes often requires destructive forensic testing that happens only after suspect items have made it into our supply, but NIST researchers have a proactive solution that lies just beneath the surface.

Similar to a QR code, we can create a unique and permanent identification code for each product by implanting electromagnetically active clusters of atoms into its physical structure. NIST’s nanoscale implanting is a difficult-to-duplicate solution. Since the patent, our researchers have moved ahead with this idea, using atomic force microscopy as an even simpler implanting technique.

Icemaker, Process for Controlling Same and Making Ice (Patent 10,174,981)

Year Granted: 2019

Inventor: David Yashar

Cool down with our next addition to the Invent Calendar. Icemakers in refrigerators operate by cycling through a series of steps that are completely separate from the refrigerator’s own cycle. This invention synchronizes the two cycles to maximize the efficiency of both.

Hub and Spoke System for Detecting and Locating Gas Leaks (Patent 10,228,490)

Year Granted: 2019

Inventors: Greg Rieker, Ian Coddington, Nathan R. Newbury, Kuldeep Prasad and Anna Karion

Today’s addition to the Invent Calendar exhibits one of many practical uses for the optical frequency comb, a technology for which NIST researcher Jan Hall shared a Nobel Prize in Physics in 2005. We can use frequency combs to shine light over the air and identify chemicals based on the colors of light they absorb.

In this case, researchers developed a device using frequency comb technology to specifically scan for trace gases in the environment across kilometer-scale distances. Not only can the instrument identify which gases are in the atmosphere (around gas fields and storage facilities, for example), but it can also help determine where they’re coming from.

The system, borne from a collaboration between researchers at NIST and University of Colorado, spurred a commercial company called LongPath Technologies. Get the details on its journey from lab to market in this Taking Measure blog post.

Photon Momentum Sensor (Patent 10,234,309)

Year Granted: 2019

Inventors: Aly Artusio-Glimpse, John H. Lehman, Michelle Stephens, Nathan A. Tomlin, Paul A. Williams, and Ivan Ryger

From welding car parts to crafting engine components with 3D printers, lasers play lots of roles in manufacturing. We can save time and costs by accurately knowing the laser power used when a part is being made or modified, which helps to produce more reliable manufactured parts overall.

That’s where our photon momentum sensor (which we call the Smart Mirror) comes in, measuring the force of photons bouncing off of the mirror shown here. It provides the ability for real-time laser power measurements while the lasers are being used. The Smart Mirror is designed to eventually serve as a compact, consistent tool that could be embedded at the end of a robotic arm or in a laser welding system to provide the robust, yet accurate measurements necessary on the factory floor.

Dual Dielectropheretic Membrane for Monitoring Cell Migration (Patent 10,514,359)

Year Granted: 2019

Inventors: Darwin R. Reyes-Hernandez and Brian Nablo

Organs on a chip: It’s not science fiction, just science. Systems such as this invention can imitate the interactions of cells in the body (even a specific organ, such as the lungs or liver), which helps us determine a medical therapy’s usefulness. We can track the health of cells before and after treatment with drugs.

Here’s how ours works: Electrical measurements on both sides of this microfluidic system act as signals, changing as cells migrate through its porous membranes. The controlled system allows real-time, quantitative measurements and simplifies the conventional process of counting cells, which can be tedious and only completed after the migration finishes.

One of the inventors dives into the details in this Taking Measure blog post.

Optomechanical Gravimeter (Patent 10,545,259)

Year Granted: 2020

Inventor: Felipe Guzman, Michael Lee Kumanchik, M. Jacob Taylor and Jon R. Pratt

Projects happening outside of our atmosphere require highly sensitive sensors that can measure forces acting on spacecrafts, particularly for high-accuracy navigation and drag-free flights.

Cue NIST. This invention can lead to all of these devices and measurements: gravimeter, seismometer, gradiometer, low frequency inertial sensing and accelerometer. While current commercial systems that perform similarly weigh several kilograms and are the size of a backpack, NIST’s optomechanical gravimeter is highly compact and weighs about 30 grams.

3D Printing of Composition-Controlled Copolymers (Patent 10,625,470)

Year Granted: 2020

Inventors: Jirun Sun and Young Jong Lee

Conventional photo-curing 3D printing uses visible or ultraviolet light to solidify a liquid layer by layer into a 3D structure; however, it’s applicable only to single-component products. The new invention of a 3D photo-curing process enables users to continuously control a mixture's material composition while printing. The resulting printed object can have uniquely optimized chemical, biological and mechanical properties obtainable by only 3D-composition-varying construction. That means, all in one print, manufacturers can produce a 3D object with complex geometry and unique properties to suit their specific needs.

One day, you might see the results of this invention when you look in the mirror. The process can help with printing customized flat lenses and personalized high-performance medical implants such as dental implants, cartilage replacements and more.

Collaborative Robot Motion and Force-Torque Gauges (Patent 10,737,390)

Year Granted: 2020

Inventors: Nicholas G. Dagalakis and Yong Sik Kim

Promising to revolutionize the manufacturing industry, state-of-the-art industrial robots on the factory floor can have multiple arms and be programmed to work side by side with humans. However, it’s difficult to measure the performance of multiple arms all operating together.

The patent motion and force-torque gauges measure the properties of multiple arms when they are working together in a coordinated synchronized manner to transport, position and manipulate objects. In doing so, they identify errors in accuracy, repeatability and reproducibility so that manufacturers can improve difficult operations, such as grinding, moving heavy workloads and negotiating sharp trajectory turns.

Active Security Token with Security Phantom for Porting a Password File (Patent 10,778,436)

Year Granted: 2020

Inventors: James Dray Jr.

For as long as we still use passwords, we will still require secure password management. Today’s invention describes a way to store a database of credentials on software and hardware security modules (such as smartcards and USB security tokens) that do not offer native password database storage capabilities.

Amino Acid-Specific Binder and Selectively Identifying and Amino Acid (Patent 10,836,798)

Year Granted: 2020

Inventor: John Marino, Zvi Kelman and Jennifer Tullman-Arbogast

Genome sequencing promises major leaps and bounds for health and medicine, but for now, genomes tend to fall short of explaining or predicting biological systems or human health and disease. That’s partly because they do not fully determine the complete set of proteins (proteomes) found in a complex biological system. We need to measure the proteomes thoroughly, which is where today's invention comes in.

NIST researchers developed protein-based sensors that enable the readout of the amino acid sequence that makes up a protein. This technology, spurred from a competition among NIST’s researchers to prove their innovations had a clear pathway to commercialize, is now in the hands of a startup company with an exclusive license.

Optical Flow Meter for Determining a Flow Rate of a Liquid (Patent 11,035,707)

Year Granted: 2021

Inventors: Gregory Cooksey, Paul Patrone and Anthony Jose Kearsley

Medical diagnostics, molecular biology, pharmaceuticals, nanotechnology — many fields depend heavily on exact control over microfluidics at ever smaller volumes and on accurate analyses of the liquids’ properties.

Today’s chip-scale invention combines microfluidics and optical technology to make accurate measurements of liquid flows, which can be critical for advancing biomedical devices that depend on the way materials move at the micro and nanoscale. This matters for the delivery of nutrients and drugs from a culture of cells to a sensor, or within an organ-on-a-chip system (such as the patent from Dec. 24 in our Invent Calendar). Learn more about NIST’s work in microfluidics and chip-scale technology.

Data Block Matrix (Patent 11,175,826)

Year Granted: 2021

Inventors: D. Richard Kuhn

Patents can extend into the digital realm, too. This data structure (aka block matrix) provides the security of blockchain, letting a person link together records in an ongoing way, while also allowing the revision or deletion of arbitrary records. That way, we can be sure that the remaining pieces of data in the chain remain unchanged.

This capability could be useful for complying with meeting privacy requirements such as the European Union General Data Protection Regulation, which requires that organizations make it possible to delete all information related to an individual at that person's request. Conventional blockchains are incompatible with this requirement.