Reduced-Scale Test to Assess the Effect of Fire Barriers on the Flaming Combustion of Cored Composites

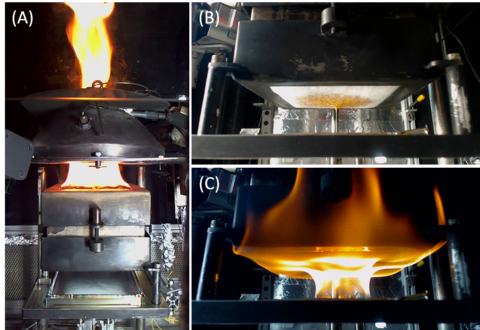

This study proposes a bench-scale fire test methodology based on the cone-calorimeter to characterize mass and heat transfer phenomena in multi-component products containing a flammable core and superficial layers that may act as fire barriers; hereafter referred to as the "Cube Test". The Cube Test assesses the propensity of a material or an ensemble of materials to produce a pool fire by measuring the time required to generate liquid products and induce mass transfer of liquid products from the bottom of the specimen. In this study, the Cube Test is applied to material assemblies used in residential upholstered furniture (RUF).

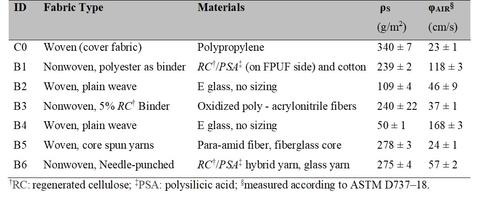

A cube shaped specimen of flexible polyurethane foam with nominal dimensions of (108 × 108 × 108) mm3 was used as the specimen core in all experiments. Barrier fabrics B1 to B6 were commercial fire barriers that did not contain halogenated/organo-phosphorous fire retardants. Fabric C0 was a polypropylene cover fabric. The selected fire barriers were intended to cover a variety of commercially available products (non-woven/woven, thermally thin/thick, high/low air permeability) and a broad range of materials including cellulosic fibers, E-glass fibers, para-amid fibers, polysilicic acid fibers, oxidized polyacrylonitrile fibers, and combinations thereof.

Data

Spreadsheets containing the data from the experiments summarized in the test matrix to the right can be downloaded in the ZIP file provided below. Information about the instrumentation layout, including sensor types and uncertainties, can be found in the reference cited below.

- ZIP file with test data (Microsoft Excel files)

Videos

References

- Zammarano M, Shields JR, Leventon I,et al. Reduced-scale test to assess the effect of fire barriers on the flaming combustion of cored composites: An upholstery-material case study. Fire and Materials. 2020;1–13. https://doi.org/10.1002/fam.2910

Contacts

-

(301) 975-5244