Beamline 3: Extended Range Monochromator for Ultraviolet and Extreme-Ultraviolet Optical Properties and Calibrations

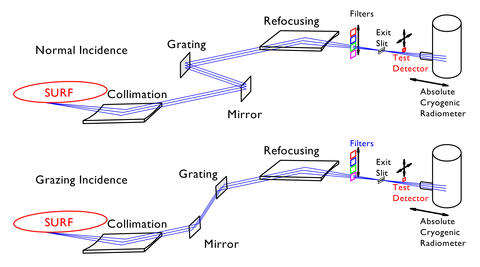

The extended range monochromator is based on a unique design that allows illumination of the gratings in both grazing and normal incidence, thus covering the whole wavelength range from soft x-rays to the visible with high throughput in a single instrument. When this monochromator was first installed on the x-ray ring at the National Synchrotron Light Source, it was the first of its kind. Now similar designs are common at many third-generation light source facilities.

In brief, synchrotron radiation is imaged using unity magnification onto the exit slit using a set of two equal off-axis parabolic mirrors, the first to collimate and the second to refocus. Two reflecting elements are installed in the region of the collimated beam between the two mirrors. At SURF III element one is usually a mirror and the dispersive grating is the second element. The mirror and grating are translated and rotated simultaneously so that the beam emerging from the monochromator is fixed.

A set of filters is installed on a linear feed through in front of the exit slit to suppress higher order reflections of the grating and establish the desired spectral purity. The available filter materials are carbon, boron, beryllium, aluminum, magnesium, tin, indium, magnesium fluoride, silicon dioxide (fused silica), and glass (BK7).

The gratings are installed on turrets with six available positions. Currently, only two gratings are used. In the wavelength range from 5 nm to 100 nm a grating with a line density of 150 lines per mm is used and from 100 nm to 400 nm a grating with 600 lines per mm is in service. They are plane gratings with gold coating. The monochromator allows operation of these gratings on-blaze for most of the wavelength range, which increases grating efficiency significantly.

While several end stations can be installed at the end of the beamline, the most frequently used accommodates both reflectometry measurements and detector calibrations.

Beamline 3: Detector Radiometry

NIST has operated several facilities in the past the perform extreme-ultraviolet and ultraviolet detector calibrations. At SURF BL-4 was used to calibrate detectors between 135 nm and 320 nm wavelength and BL-9 to calibrate them between 5 nm and 50 nm, leaving the wavelength range from 50 nm to 135 nm covered only by a laboratory facility based on a plasma discharge source, not the synchrotron source. Generally, customer devices are calibrated against working standard photodiodes using a substitution method. Currently, one of the biggest challenges in photodiode radiometry is the identification of suitable detectors that exhibit both high spatial uniformity, low electrical noise, and sufficient radiation hardness.

The scale realization was based on measurements with both absolute-cryogenic radiometers (ACR) and ionization chambers (IC). The scale was realized with an ACR using beamline 4 from 135 nm to 320 nm and using beamline 7 from 7 nm to 35 nm. On beamline 9 and in the plasma discharge facility, single and double ionization chambers were used for the remaining wavelength range.

Since the extended range monochromator has been installed all detector calibrations can be performed on beamline 3, which covers the wavelength range from 5 nm to 400 nm without leaving an uncovered range.

Currently we are planning to perform a scale realization using this beamline for the whole wavelength range from 4 nm to 400 nm. Overlap with the wavelength coverage of the Ultraviolet Scale Realization Facility (UV SRF), which has been used in the wavelength range from 200 nm to 400 nm, is intentional and provides redundancy.