Kibble Dynamic Force Reference

Static force, such as the weight of a motionless mass, is easily determined using scales, balances, load cells and the like because it does not change over time. It is straightforward to calibrate such devices with an unvarying force such as gravity acting on a mass.

Dynamic force, however, which changes continuously as it is applied — as in automobile crash testing, fatigue testing, and application of machining forces — has historically been difficult to measure. In many applications, a time-varying force causes large errors in instruments designed to measure static force. It is thus necessary to calibrate the response of these instruments to dynamic forces.

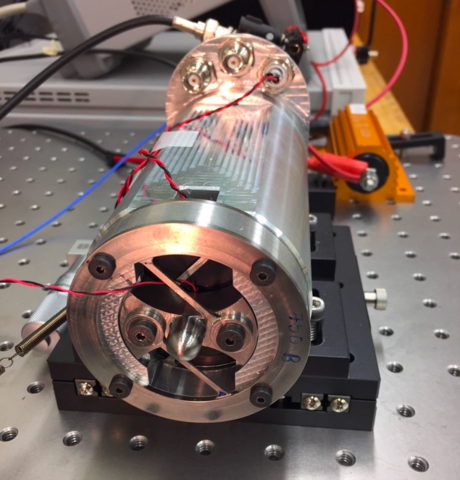

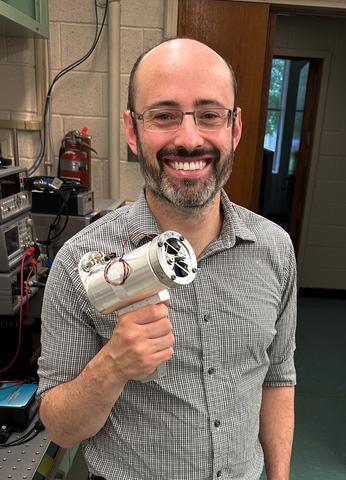

To meet that need, NIST scientists have devised the Kibble Dynamic Force Reference (KDFR), a traceable dynamic force source based on the same electromagnetic principle used in a Kibble balance to generate a force that exactly offsets the static weight of an unknown mass.

Like that instrument, the KDFR is a primary standard — that is, it does not require calibration because its operation is based on fundamental physical interactions. But instead of generating a single force, the portable KDFR generates waves or pulses of repeated dynamic force while a separate sensor detects the vibrations produced in response. The pulse frequency ranges from a few hertz up to several kilohertz, with a target uncertainty of about 1% in the amplitude of the force generated by the KDFR. The sensor samples the response at several times the frequency of the applied force to detect the dynamic effects.

Theoretically, it is possible to determine an object’s impulse response to dynamic force at a particular point by striking it only once and observing how it rings. But there is inevitably some noise in the response. So as a practical matter, it is necessary to apply many identical pulses in succession to improve the signal-to-noise ratio and get an accurate measurement of the impulse response.

The KDFR can apply known dynamic forces to a wide variety of mechanical structures. It could potentially be used for structural testing of vehicles, buildings and bridges. It could also be used to calibrate sensor systems for measuring dynamic forces, such as in materials testing (dynamic tensile testing, fatigue testing, impact testing) and in aerodynamic balances in wind tunnel tests.

The Technology

The Kibble approach provides an accurate determination of the mechanical force generated by a current flowing in a wire coil that moves in a magnetic field — from measurements of current, voltage and velocity — without requiring knowledge of the magnetic field or the geometry of the coil.

According to the Lorentz force law, a current-carrying wire in a magnetic field experiences a force perpendicular to the current and to the magnetic field. A coil embedded in a radially pointing magnetic field thus experiences a force along the axis of the coil.

Accurately knowing this force, so that it can be used as a standard, would ordinarily require knowing details of the three-dimensional magnetic field and the geometry of the coil moving through the field to high accuracy, which is difficult. However, Faraday’s law allows the relevant quantity to be calculated from the voltage generated between the ends of the coil wire when it moves through the magnetic field at a known velocity.

In a mass-measuring Kibble balance, the current is adjusted to generate a force that exactly offsets the static force exerted by an unknown mass, with the coil stationary. In a separate step, the coil is moved with no current flowing through it and the voltage generated between its ends is measured.

Separating the current and voltage measurements into two steps requires a high degree of uniformity and stability of the magnetic field, which is difficult to achieve in a dynamic measurement. Therefore, the KDFR measures the current, voltage and velocity simultaneously and synchronously at a rapid sampling rate (tens of kilohertz), providing the generated force output in real time. For such a simultaneous-mode device, the electrical impedance (resistance and inductance) of the coil creates additional voltage components that must be removed by either design or analysis.

Advantages Over Existing Methods

Measurements of dynamic force generally do not correspond to those obtained by a statically calibrated force sensor. That difference results from the inertia of system components that accelerate in the presence of the dynamic force, and also because of the frictional (damping) forces that moving material experiences.

To account for those effects, dynamic system models are sometimes used. But they are generally of limited accuracy and often require measurements from additional sensors.

Accurate measurements can, however, be achieved if the sensor systems are calibrated (a) dynamically and, importantly, (b) as assembled for the measurement, rather than relying on an ex-situ calibration of the force sensor in which it is removed from its measurement setting. Because the KDFR is a portable, primary force generator, it can calibrate measurement systems on-site as assembled.

Existing methods for generating known dynamic forces (for calibrations and other applications) commonly use a calibrated force sensor (piezoelectric or strain gauge-based) in the force-application chain. These are not primary standards and therefore have increased uncertainty and require periodic recalibration.

The most commonly used such secondary force standard is a so-called impact hammer or impulse hammer, which is a hand-held calibrated force sensor (typically piezoelectric) that is struck against the target system in order to apply a pulse force. In using impact hammers, the fact that the output force is a single pulse limits the ability to determine system frequency responses.

In contrast, the KDFR can be driven to produce a variety of force output wave profiles. Sinusoids and frequency sweeps (chirps) are particularly well suited for measuring frequency response amplitude and phase with high resolution.

Applications

The device produces an accurate, traceable dynamic force output, applicable wherever needed. Expected applications include: (1) modal testing, which identifies the natural vibration modes of structures in civil engineering, automotive, aeronautical and marine settings; and (2) calibration of force-measurement systems for dynamic measurement applications such as fatigue testing of materials, impact testing of materials and consumer devices, crash-test dummy measurements, aerodynamic force balances, and measurements of cutting forces in machining operations.

Key Paper

A. Chijioke and N. Vlajic. Portable high-frequency electrodynamic force standards. IEEE Conference on Precision Electromagnetic Measurements. July 2018. DOI: 10.1109/CPEM.2018.8501146

Key Patent

A. Chijioke and N. Vlajic. Dynamic force contactor, providing a dynamic force, and calibrating a force sensor to be traceable to the international system of units. United States Patent US 10641663. May 5, 2020.

Contacts

-

(301) 975-3898

-

(301) 975-2240