How Do You Ensure That a Tape Measure Is Accurate?

You need to measure length accurately to do things like make a dress, build a house, survey a plot of land, or determine if the home team made a first down on the football field. These length measurements and many others are often made with the help of a measuring tape.

Some manufacturers use highly accurate reference tape measures to print their familiar hash marks on the tape. Some are printed using computer-controlled ink printers with tiny printheads to ensure the markings are laid down accurately.

Once the tapes are printed, manufacturers check random samples for accuracy. They run the tape along a flat bench, holding it tightly in place with a specific tension from a mechanism or weight. Alongside the tape is a microscope, mounted on a moving carriage. The manufacturer aims the microscope at the tape’s hash marks and moves it from one end of the tape to the other.

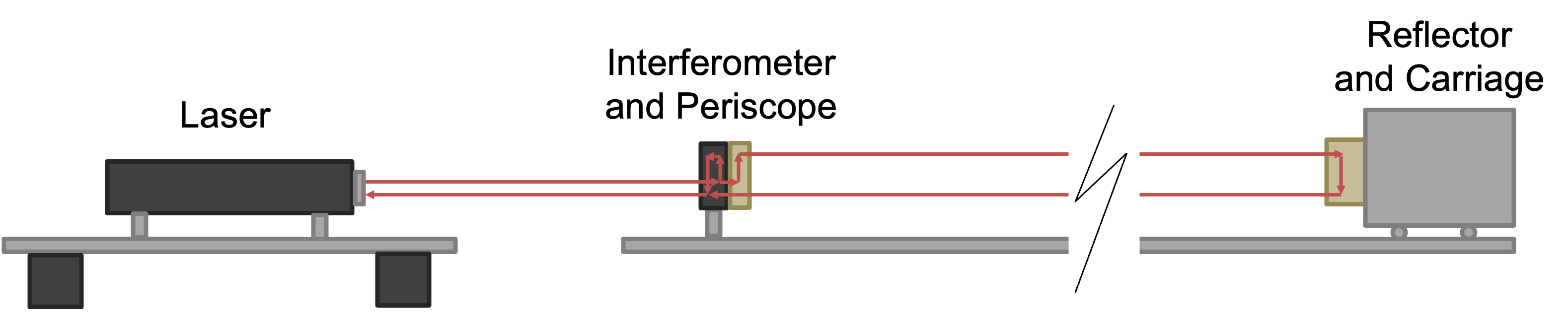

At one end of the bench is a device called a laser interferometer, which can precisely measure distances along the tape. Laser interferometers work by splitting a laser beam in two. One of the beams, the reference beam, goes directly to a detector, while the other, a measuring beam, goes toward a reflector on the side of the microscope. The measuring beam bounces off the reflector and rejoins the reference beam back at the detector.

Each laser beam is a vibrating electromagnetic wave, which consists of peaks and valleys. When two laser beams combine, they overlap and produce a bright signal if their wave peaks line up perfectly, and a dark signal if the peaks of one wave line up with the valleys of the other. The signal cycles between light and dark as the reflector moves across the tape. The system counts the number of light-dark cycles and translates this into the distance that the reflector has moved by plugging in the value of the laser light’s wavelength (one wavelength is the distance between two successive wave peaks).

As the microscope moves over the tape, manufacturers can compare the position of the hash mark on the tape with the distance reported by the interferometer. If the tape is accurate to within an acceptable tolerance, it passes the test, and the batch that it comes from can be sold. To be used for buying and selling goods, a 1.82-meter (6-foot) tape should be accurate to within 0.79 millimeters (1/32 inch), according to NIST Handbook 44, a sourcebook for many measurement standards. Even more accurate tapes are available, such as those used for the Olympics or to measure the level of oil tanks, but they are more expensive.

At NIST, researchers periodically verify the primary physical length standards that manufacturers use to print their tapes and other length standards used in industry. Scientists in NIST’s tape calibration laboratory can measure a meter (3.28 feet) with a standard uncertainty of plus or minus 350 nanometers (billionths of a meter). For perspective, a human hair is anywhere from approximately 17,000 to 180,000 nanometers in diameter (0.017 to 0.18 mm).

The total measurement uncertainty of a typical tape is higher due to additional contributing factors, such as the need to make repeatable measurements on the tape’s many hash marks. In NIST’s tape tunnel, which is over 60 meters long (almost 200 feet), researchers can measure a tape with an accuracy of 0.1 mm, about the thickness of a sheet of paper.

And you need all this accuracy because the world is an imperfect place and errors inevitably build up during the manufacturing process, conspiring to make the tape less accurate. Manufacturers, with guidance and help from places such as NIST, compensate for these errors as best as they can to produce tapes with the right level of accuracy for the job.