Summary

Advanced manufacturing processes create novel materials and components with superior properties and performance, enhancing the precision, efficiency, and capabilities of traditional manufacturing processes. These processes also offer possibilities for energy and cost savings, as highlighted by recent national strategies for advanced manufacturing. However, these advanced processes pose unique challenges in establishing the relationships between material processing, structures, and properties due to the complexity of material structures and their behavior under processing conditions.

To address these challenges, we develop measurement solutions to characterize the structural and microstructural evolution of materials in situ during manufacturing. These solutions, along with the high-quality data they generate, are essential for the industry to optimize and control the final materials' performance.

Description

Understanding material structures in advanced manufacturing is crucial because it enables precise control over material properties, leading to improved performance, efficiency, and cost-effectiveness in production processes. However, this understanding poses many challenges, such as the heterogeneity in material structures resulting from manufacturing processes that require structure characterization over different length scales and kinetics-driven changes that demand in situ characterization. To address these challenges, the Materials Structures and Data Group at the National Institute of Standards and Technology has developed metrologies that combine a broad range of high-precision advanced structure characterization tools to accurately assess and monitor the evolution of material structures during manufacturing. In particular, we develop and exploit high-brightness, high-energy synchrotron X-ray scattering methods to rapidly probe materials’ structure. We then combine these data with neutron scattering and various modes of electron microscopy for an in-depth understanding of the material’s behavior. This metrology and the foundational data it generates provide the industry with much-needed insights to ensure the optimal performance and reliability of the final products.

This metrology has provided essential understanding of material structure evolution under processing conditions across a wide range of material systems and applications, including metal and ceramic processing, carbon mitigation, materials sustainability, and advanced materials development. Currently, we have two focus areas: additive manufacturing and alternative processes for energy-intensive industries.

1. Additive Manufacturing

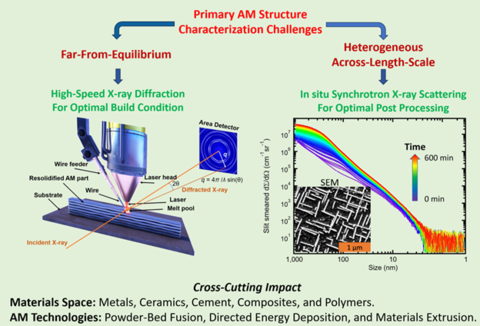

Additive manufacturing (AM) offers design flexibility and enables industrial innovation across many sectors, notably medical, aerospace, and defense. It also represents an essential component of U.S. domestic supply chain integrity. However, AM processing conditions can be extreme and highly nonequilibrium. For example, typical laser-powder bed fusion of metal AM can experience cooling rates exceeding 1,000,000 K/s. Such processing conditions make it extraordinarily difficult to measure the material structure evolutions. The lack of control over the material structure presents a significant hurdle in the qualification and certification of AM parts, preventing their widespread industrial adoption.

To address these challenges, we have developed solutions capable of monitoring structure evolution at every step of the process, from the initial rapid solidification to the required post-built heat treatment. We have demonstrated that phase-transformation sequences in additively manufactured metal alloys are controlled by kinetics and dependent on cooling rates. Our work has also revealed the formation kinetics of unexpected deleterious phases in AM alloys and developed mitigation strategies. Importantly, our solutions are a critical component of the AM benchmark series, providing essential and much-needed calibration datasets for the AM modeling community to calibrate their models and enable more reliable predictions.

2. Alternative Processes for Energy-Intensive Industries

Global competition in industrial sustainability increasingly demands alternative processes for energy-intensive industries. Low-energy processes conserve energy and resources, reduce environmental impacts, and strengthen supply chains through local production. These processes are crucial for foundational industries like steel, ceramics, glass, and cement, which require highly energy-intensive processing. Accurate structural characterization is essential for validating these new processes. In this emerging area, manufacturers are increasingly turning to NIST for critical data to validate new energy-efficient materials and processes, along with international standards leadership, both of which are essential for the U.S.’s global market competitiveness.

Similar to additive manufacturing, low-energy processes are kinetics-driven and require in-situ structural characterization for materials optimization. Our work in this space has successfully demonstrated that hydrogen-assisted steelmaking can reduce Fe3O4 to Fe at temperatures as low as 350 °C, compared to the typical 2,000 °C required by an industrial blast furnace. Our in-situ measurements provide the transformation sequence and kinetics. Additionally, we performed in-depth structural characterization of cold sintering, a new paradigm in ceramic sintering, another energy-intensive industrial process. We demonstrated that cold sintering can sinter a range of ceramics at temperatures at least 1,000 °C below their conventional sintering temperatures. Our structural metrology revealed the formation of previously unknown grain boundary phases that promoted the cold sintering step and established the interfacial transformation kinetics.

In summary, our project aims to provide industry with world-leading measurement capabilities for qualifying new materials and processes through advanced structure characterization, ensuring economic security and promoting global competitiveness in advanced and sustainable manufacturing.