Mercury Thermometer Alternatives: Platinum Resistance Thermometers (PRTs)

Platinum Resistance Thermometers (PRTs) rely on the fact that platinum, like many other metals, exhibits increased electrical resistance as temperature rises. For example, a conventional PRT designed to provide 100 Ω at 0 °C has a resistance in the neighborhood of 80 Ω at -50 °C and 120 Ω at 50 °C, or a sensitivity of about 0.4 Ω per degree. PRTs constructed to particularly exacting specifications, termed Standard Platinum Resistance Thermometers (SPRT), are named as the defining measurement tools for interpolating temperatures under ITS-90. In general, PRTs can have high accuracy (0.01 °C), stability, and repeatability across a wide range of temperatures from -200 °C to 500 °C.

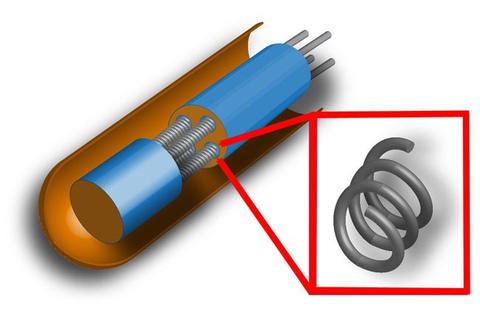

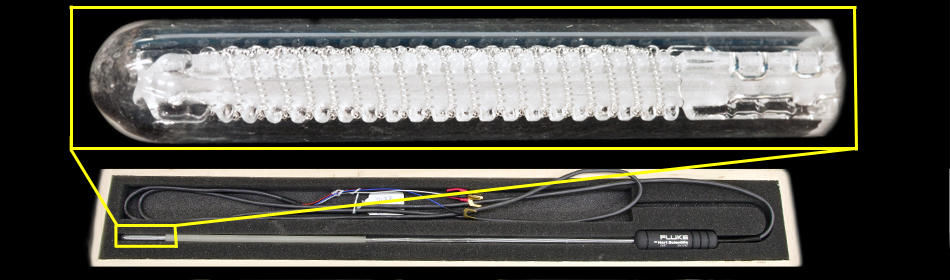

Typically the platinum element is formed into thick or thin films, or the platinum wire is arranged in two, three or four helical coils (see diagram, right) – the more coils, the higher the sensitivity. The film or wire is placed inside a glass or ceramic enclosure, and can be supported by loose or compacted MgO. Platinum-based leads connect the probe unit to the thermometer electronics, which convert the electrical signal to temperature.

PRTs are broadly divided into two groups: Industrial PRTs (IPRTs) and SPRTs, depending on sensitivity and robustness. ASTM and IEC define several classes of PRTs, each with a different set of specifications. An ASTM "Class A" unit, for example, has an out-of-the-box tolerance — maximum permissible error — that ranges from 0.47 °C at -200 °C to 0.13 °C at 0 °C to 0.98 °C at 500 °C.

Users considering an IPRT should consult ASTM E1137 for standards and specifications.

NIST calibrates these devices from -196 °C to 550 °C

Advantages

- Wide temperature range

- Resistance-temperature relationship is well characterized.

- Rugged construction in IPRTs

- Cost of an IPRT is less than an SPRT.

- Available in different shapes and sizes – application specific

- Can be used with a digital temperature read-out device.

Disadvantages

- Mechanical shock and vibration will cause drift.

- Deterioration at elevated temperatures (e.g., >500 °C)

- 2- and 3- wire devices need lead-wire compensation.

- Non-hermetically sealed IPRTs will deteriorate in environments with excessive moisture.

- Not as accurate as an SPRT

Any mention or image of commercial products within NIST web pages is for information only; it does not imply recommendation or endorsement by NIST.

Contacts

-

Questions about Mercury Thermometer Alternatives?