Mercury Thermometer Alternatives: Thermocouple

Thermocouples rely on the fact that when a conductor is exposed to a thermal gradient, it will naturally generate a voltage. (This is known as the thermoelectric effect.) If two different conductors are arranged in a circuit across a temperature gradient, each conductor will generate a different voltage. The net voltage difference will be proportional to the magnitude of the temperature gradient, customarily in the range of a few microvolts per degree, and that voltage is converted to a temperature by the thermometer electronics.

Because thermocouples are sensitive only to differences between two temperatures, one circuit component must be kept at a well-characterized reference point (for example, the ice melting point) while the other component is at the temperature to be measured.

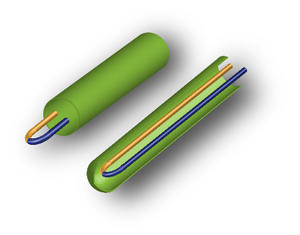

Modern thermocouples typically use two different alloys of elements such as iron, nickel, chromium, manganese, aluminum, tungsten, rhenium and more -- including platinum and gold alloys in some models -- as well as pure metals. Each combination has different characteristics, and thus different standards as set by ASTM. To see a list of types and specifications, see ASTM E230.

Thermocouples are relatively inexpensive, can endure very low and very high temperatures, and can be constructed from a wide variety of materials. Depending upon class type (base metal, noble metal and pure metal), they can resolve temperature differences of about 1 °C, 0.1 °C and 0.01 °C respectively.

NIST calibrates these devices from -196 °C to 2100 °C

Advantages

- Comparatively inexpensive

- Wide temperature range (-270 °C to 2100 °C)

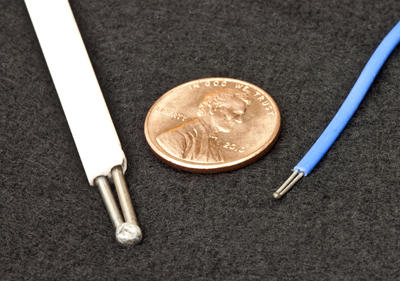

- Small (down to 0.25 mm diameter)

Disadvantages

- Small signals, limited temperature resolution (0.01 °C to 1 °C) in some models

- Thermocouple wires must extend from the measurement point to the readout or ice-point junction.

- At higher temperatures (>500 °C), thermocouples may undergo chemical and physical changes, leading to loss of calibration.

- Recalibration for use above 200 °C is difficult in base-metal units.

| TC type | Ref. func. range, °C | Nominal composition majority component in italics, % in mass | |

|---|---|---|---|

| Positive leg | Negative leg | ||

| B | 0 to 1820 | platinum-30% rhodium | platinum-6% rhodium |

| E | -270 to 1000 | nickel-chromium alloy | copper-nickel alloy |

| J | -210 to 1200 | iron | copper-nickel alloy |

| K | -270 to 1372 | nickel-chromium alloy | nickel-aluminum alloy |

| N | -270 to 1300 | nickel-chromium-silicon | nickel-silicon-magnesium |

| R | -50 to 1768 | platinum-13% rhodium | platinum |

| S | -50 to 1768 | platinum-10% rhodium | platinum |

| T | -270 to 400 | copper | copper-nickel alloy |

Contacts

-

Questions about Mercury Thermometer Alternatives?