Mercury Thermometer Alternatives: Thermistor

Thermistors (thermal resistors) are based on extremely well characterized relationships between temperature and electrical resistance in different semiconductor materials.

Instead of metal sensors, as in platinum resistance thermometers (PRTs), thermistors usually employ polymers or ceramics – usually semiconductors made by sintering mixtures of metallic oxides such as manganese, nickel, cobalt, copper, iron, and more.

Depending on sensor composition, thermistors can exhibit either increased or decreased resistance as temperature increases. Most commercial models are "negative temperature coefficient" units in which resistance decreases with temperature. Positive temperature coefficient models are customarily used for specialized applications over a very narrow temperature range, primarily as control and safety devices.

Both types tend to perform best from about -50 °C to around 100 °C. Elevated temperatures will excessively age the thermistor and cause drift.

Thermistors have high stability if used over a narrow temperature range of 0 °C to 50 °C, and can have uncertainties as low as less than 0.001 °C. This sensitivity, which is substantially higher than a PRT in the same range, results from the fact that a thermistor's resistance changes by more than a factor of 300 from –50 °C to 90 °C (about 4 percent per degree Celsius) whereas a PRT exhibits about 0.4 percent resistance change per degree in the same range.

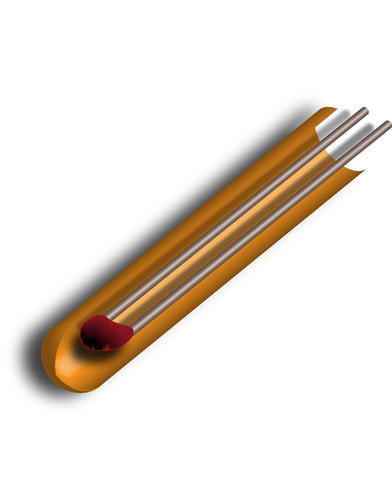

Typical thermistor probe sizes range from less than a millimeter to about 2 cm in diameter, and can take the form of beads, rods, washers, or chips. Sensors are usually encapsulated in epoxy or hermetically sealed in glass. Frequent applications, aside from temperature measurements, include temperature compensation in electrical circuits, temperature control, liquid-level measurements, power measurements, thermal conductivity, biomedical applications, and power level control.

NIST calibrates these devices from -50 °C to 100 °C, and other temperature ranges by special request.

Advantages

- Easy to miniaturize

- Rugged

- Fast response time

- Easy to use

- Inexpensive

- High sensitivity (calibration uncertainty of 1 mK over 50 °C of temperature span)

- Small-size beads may be used for point-sensing

- Stability: 4000 h at 100 °C; bead-in-glass: 0.003 °C to 0.02 °C; disc: 0.01 °C to 0.02 °C

Disadvantages

- Small temperature range

- Non-linear device

- Needs frequent checks on calibration when exposed to t > 100 °C

- Interchangeability is limited unless the thermistors are matched

- Self-heating may be large

Contacts

-

Questions about Mercury Thermometer Alternatives?