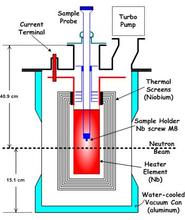

This is the general use furnace that is available for use on all instruments except HFBS and BT4. It is made up of a water cooled aluminum outer vacuum can containing a niobium resistive heating element surrounded by niobium heat shields. The sample is top loaded on a stick, but the furnace must be brought to room temperature for sample changing. The sample stick has a threaded stud for sample can mounting. Use of this system requires the assistance of a sample environment team member.

| Sample Geometry |

|---|

| Sample Holder |

Top Loading Stick with Male M8 Thread |

| Sample Access In Plane |

350o |

| Sample Access Out of Plane |

+20o |

| Maximum Sample Diameter |

4.2cm (1.65 in) |

| Maximum Sample Height |

12cm (4.72 in) |

|

|

Sample Preparation

Safety Issues

Experiment Planning

More Information:

-

- Sample Holders: The sample probe terminates in a threaded M8-1.25 stud. A user designed (NIST assistance is available) holder compatible with our probe is required. Ventilated (i.e. non-pressure building) crucible-type holders made of niobium or platinum are recommended. Any sealed sample holder must be tested off-line at the maximum desired temperature before loading into the furnace to ensure that an over-pressure burst will not occur on the beam line.

- Sample Geometry:

- Note that the beam center is 40.9cm below the top of the sample well, and the probe height is adjustable to accommodate a wide range of sample sizes.

- Your probe/sample length must be adjusted so that it DOES NOT TOUCH THE HEATING ELEMENT OR THE BOTTOM OF THE SAMPLE WELL

- The furnace must be operated under high vacuum (less than 10-4 Torr).

- KNOW YOUR SAMPLE!! Users must verify that their sample will maintain low vapor pressure (< 10-5 Torr) and not react with its surroundings at high temperature; since the heating element along with all of the heat shields in the furnace are made of niobium (refractory material that readily oxidizes at temperatures above 150 degrees Celsius).

- The furnace requires high vacuum and proper water flow for safe operation. There are two safety interlock systems: One is for over-temperature and is controlled by the small temperature reader on the upper right of the control unit. The vacuum gauge and the water-flow switch share the other. The furnace will not operate if either of these interlocks is not functioning.

- Set appropriate current limits. If using the manual ramping, do not jolt the furnace with high current spikes. Slowly increment the output limit setting and/or ramp your setpoint for smooth operation.

- Note that this is a high temperature furnace that performs best at higher temperature.

- Plan ahead. At most it will take 2 hours for the sample to reach 1600oC.

- Leave time at the end of the experiment to allow the sample cell to cool in order to remove the sample stick.

- Design the experiment with proper sample mounting and ultimate sample temperature requirements in mind.