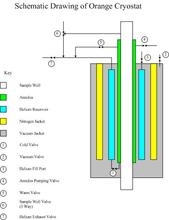

ORANGE CRYOSTATS

There are many variations of the orange cryostat here at the NCNR, such as the 70mm version shown above, but they all work in the same way. The design of the system came from scientists at the Institut Laue-Langevin (ILL) in France and is why you will hear them called ILL cryostats as well. The OCs are all top loading and use the same sample mounting surface on their respective sample sticks. The main differences are the sizes of the sample wells and the shapes of the cryostats themselves. Which cryostat you should use depends on the instrument you are using, the size of your sample and other factors. Choose your cryostat from the table below to access more detailed information.

| System Description | Sample Well Diameter | Available Instruments | Temperature Range (K) |

|---|---|---|---|

| OC-50 | 50mm | All Except HFBS | 1.5 - 300K |

| OC-70 | 70mm | All Except HFBS | 1.5 - 300K |

| OC-100 | 100mm | All Except HFBS, NSE, BT4 | 1.5 - 300K |

| OC-HFBS | 50mm | HFBS | 1.5 - 300K |

| OC-DCS-2 | 70mm | DCS | 1.5 - 300K |

General OC Information

Basic Operating Scheme

The sample is attached to the end of a sample stick and inserted into a sample well filled with helium exchange gas (i.e. heat exchange medium). The sample temperature is controlled by adjusting heater current and helium flow through a heat exchanger (HX) anchored to the sample well. The heater current is automatically adjusted by a PID loop temperature controller, while the helium flow rate is manually adjusted with valves. A "cold valve" controls the flow of liquid helium from a 10 liter reservoir into the HX (note that the reservoir is thermally isolated from the HX and held at a slight overpressure). Normally, gaseous helium leaves the HX and flows through an annular region (surrounding the well) before exiting the cryostat in one of the following ways: 1.) through a metered "warm valve" directly to atmosphere (for 4.2 Kelvin minimum temperature) 2.) through a port connected to a high capacity vacuum pump (this mode required below 4.2K). Note that you may operate over the full temperature range and refill cryogens while operating in the pumping mode, but at the expense of using more cryogens.

Other Capabilities

The capabilities stated so far have been for operation in the standard setup. When using a special setup these capabilities may change, however, many special setups have been used with success. Some of these include: gas handling, transport measurements, high pressure, etc. Any special setups should be discussed with the sample environment staff before being scheduled.

More Information:

Contacts

-

(301) 975-5295